Method for synthesizing caproic acid by catalyzing lactic acid through microorganisms

A technology for catalyzing lactic acid and microorganisms, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of hydrogen safety, low solubility, unfavorable caproic acid synthesis, increased extraction costs, and complex bacterial fermentation products. The effect of avoiding competition for organic substrates, increasing substrate selectivity, and improving substrate utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The cultivation of embodiment 1 hexanoic acid functional flora

[0036] After the culture medium was boiled, it was divided into 250ml anaerobic bottles. Nitrogen gas was introduced until the color of the culture medium changed from blue to light red until it became colorless. It was sterilized at 121°C for 15 minutes and cooled. Inoculate caproic acid flora at a ratio of 5%. Anaerobic culture at 25-35°C for 3-5 days, the bacterial cell density OD600 reaches 3-5 bacterial suspension, and set aside.

[0037] The medium components are as follows: 1.0g lactic acid, 1g casein peptone, 0.5g yeast powder, 0.5g NH 4 Cl, 0.4g NaHCO 3 , 0.1g cysteine, 0.045g K 2 HPO 4 ,0.045g KH 2 PO 4 ,0.09g NaCl,0.009g MgSO 4 7H 2 O, 0.009g CaCl 2 , 0.1mg resazurin, 1mg hemin, 1mg biotin, 1mg vitamin B12, 3mg p-aminobenzoic acid, 5mg folic acid and 15mg vitamin B6, 100ml distilled water.

[0038] Caproic acid functional flora included Clostridium sporosphaeroides with an abundance of...

Embodiment 2

[0039] Example 2 Microbial Batch Fermentation of Lactic Acid to Produce Caproic Acid

[0040] Put the culture solution containing 50g / L lactic acid into the fermenter, sterilize at 121°C for 20 minutes, pass nitrogen gas after cooling to reduce the redox potential of the medium to below -50mV, insert 5-8% seed bacterial liquid, and pass nitrogen gas again Reduce the oxidation-reduction potential of the medium to below -50mV, control the temperature at 25-35°C, pH 5.5-5.8., stir and cultivate at 100 rpm for 10-12 days, and the hexanoic acid concentration is above 20g / L. The caproic acid fermented liquid is subjected to conventional extraction processes such as distillation and rectification to obtain high-purity food-grade caproic acid.

Embodiment 3

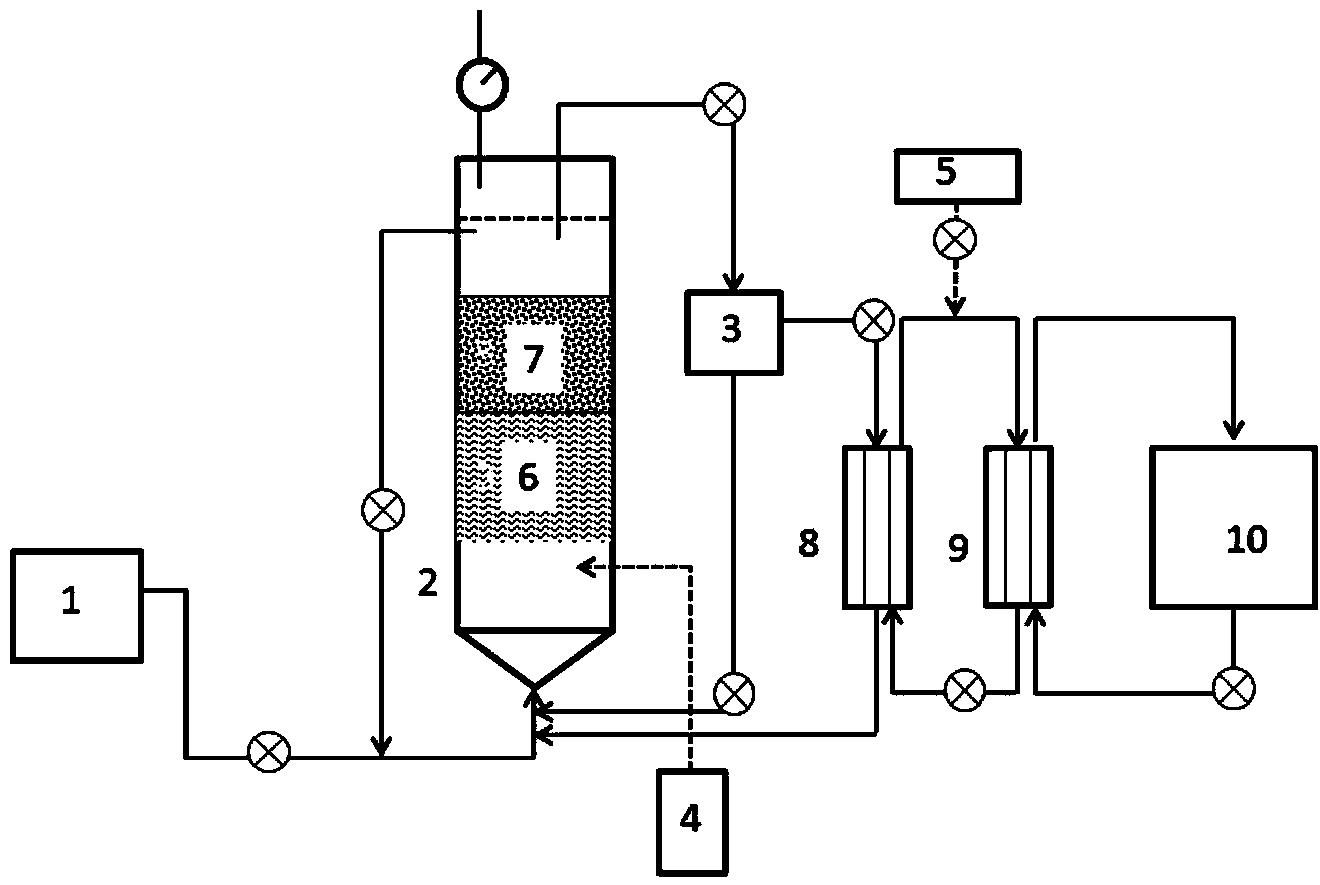

[0041] Example 3 Microbial continuous fermentation of lactic acid or lactic acid-containing wastewater to produce hexanoic acid and its on-line separation and purification

[0042] 1. Immobilization of microorganisms

[0043] The seed solution was transferred to an upflow anaerobic reactor containing lactic acid culture solution (attached figure 1 ), feed nitrogen / carbon dioxide (9:1) mixed gas, keep the reactor temperature at 25-35°C, make the bacteria adsorb to the immobilized film filler, until the concentration of the bacterial suspension in the reactor no longer drops;

[0044] 2. Production of caproic acid by continuous fermentation of lactic acid wastewater

[0045] (1) Pump 10g / L lactic acid (or lactic acid-containing wastewater) into the reactor, control HRT: 5d, anaerobic culture at 25-35°C, pH: 5.5-5.8, maintain the influent load of 2g lactic acid / L.d, run 10d;

[0046] (2) Control HRT: 2.5d, other conditions remain unchanged, the influent load is 4g lactic acid / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com