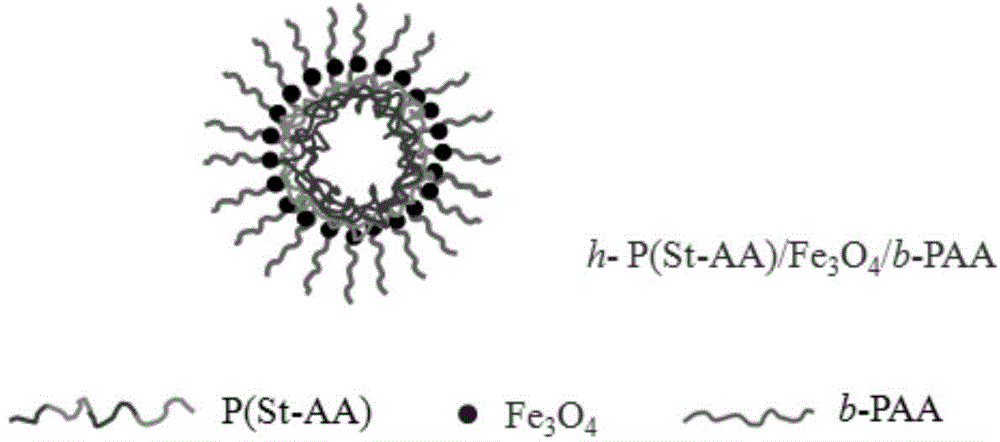

Amphipathic superparamagnetic composite hollow microsphere and preparation method thereof

A superparamagnetic and composite microsphere technology is applied in the field of amphiphilic superparamagnetic composite hollow microspheres and their preparation, which can solve the problems of poor stability, limited biomedical application effect, and small particle size adjustment range, and avoid the Decomposition, Ease of Purification and Collection, Enhanced Magnetic Responsiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

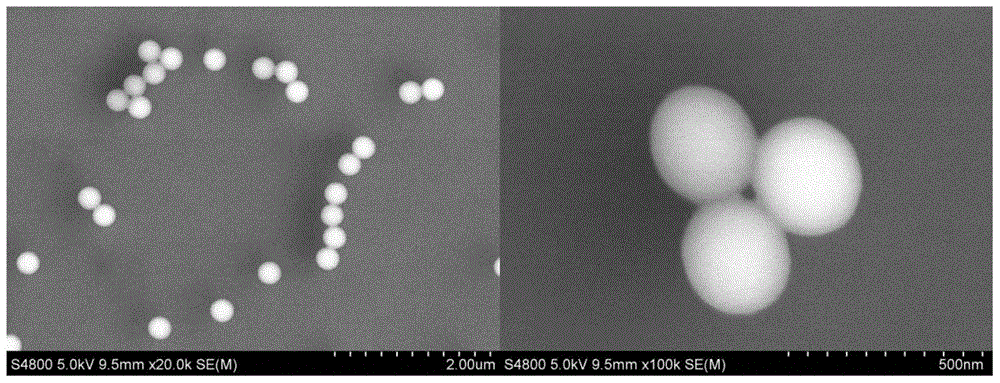

[0041] Embodiment one: preparation of copolymer solid microspheres P (St-AA) by soap-free seed emulsion polymerization

[0042] Take a three-necked bottle equipped with mechanical stirring, vacuumize and ventilate nitrogen, and repeat three times to ensure that the reaction system is anhydrous and oxygen-free; inject 45mL distilled water into the reaction system, and ventilate nitrogen for 30 minutes under mechanical stirring to remove dissolved in water. Oxygen; then inject 0.5g styrene (St) into the aqueous solution, mechanically stir to make it fully emulsified; heat the reaction system to 70°C in an oil bath, add ammonium persulfate as an initiator, and react for 3 hours to obtain polystyrene seed small Then 4.5g styrene, 1.0g acrylic acid (AA), and 5mL water were injected into the reaction system respectively, and the reaction was continued for 5 hours; after the reaction, a white emulsion was obtained; cooled to room temperature, the reaction solution was distilled under ...

Embodiment 2

[0043] Embodiment two: no soap seed emulsion polymerization method prepares copolymer solid microsphere P (MMA-AA)

[0044] Take a three-necked bottle equipped with mechanical stirring, vacuumize and ventilate nitrogen, and repeat three times to ensure that the reaction system is anhydrous and oxygen-free; inject 45mL distilled water into the reaction system, and ventilate nitrogen for 30 minutes under mechanical stirring to remove dissolved in water. Oxygen; then inject 0.5g methyl methacrylate (MMA) into the aqueous solution, and mechanically stir it to make it fully emulsified; heat the reaction system to 70°C in an oil bath, add potassium persulfate as an initiator, and react for 3 hours to obtain polymethylmethacrylate Methyl methacrylate seed pellets; then 4.5g methyl methacrylate, 1.0g acrylic acid (AA), and 5mL water were injected into the reaction system respectively, and the reaction was continued for 5 hours; after the reaction, a white emulsion was obtained; cooled ...

Embodiment 3

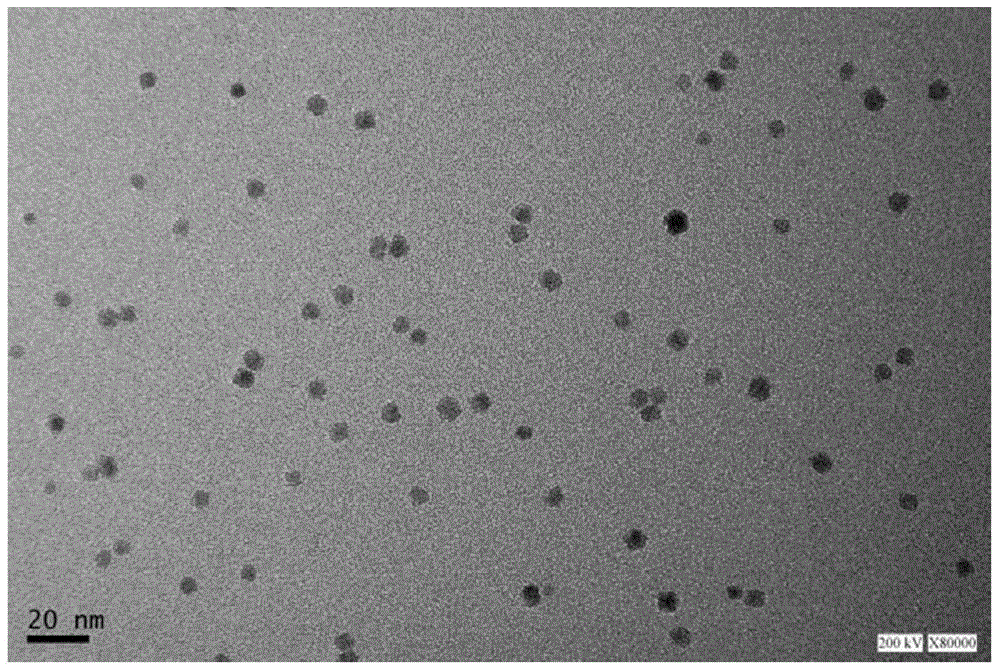

[0045] Embodiment three: polyol method prepares Fe 3 o 4 superparamagnetic nanoparticles

[0046] Take a 100mL three-necked bottle with a condenser, vacuumize and ventilate nitrogen three times, dissolve 720mg of iron acetylacetonate in 40mL of triethylene glycol and inject it into the reaction system; magnetically stir, heat in a sand bath, and slowly raise the temperature to 180°C , keep warm for 30 minutes; then rapidly raise the temperature to 278°C (the boiling point of triethylene glycol), and reflux for 30 minutes to obtain a black magnetic fluid (Fe 3 o 4 The original reaction solution of nanoparticles); cooled to room temperature, washed three times with ethanol / ethyl acetate mixed solvent with a volume ratio of 1:10, and then subjected to magnetic separation. The obtained product was dispersed in ethanol and stored at low temperature.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com