Method for preparing element doped manganese dioxide electrode materials for super-capacitors

A manganese dioxide electrode, supercapacitor technology, applied in hybrid capacitor electrodes, hybrid/electric double layer capacitor manufacturing, manganese oxide/manganese hydroxide, etc. problem, to achieve the effect of low cost, high activity and specific capacity, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

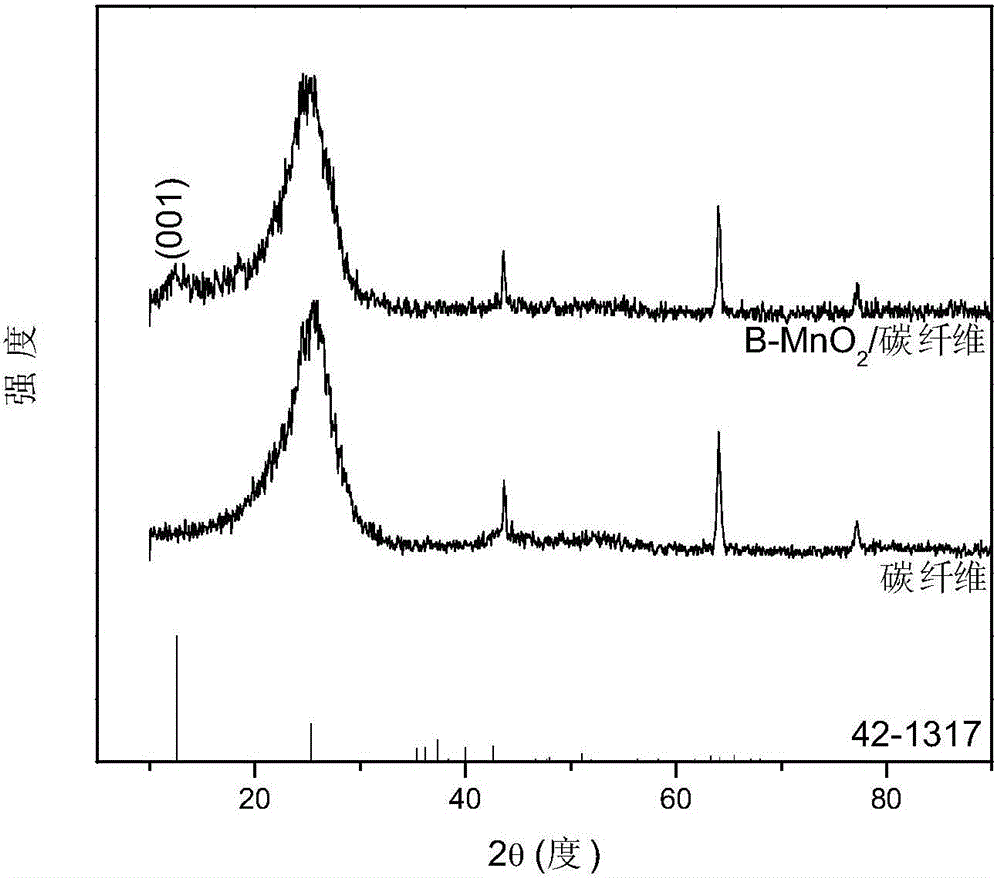

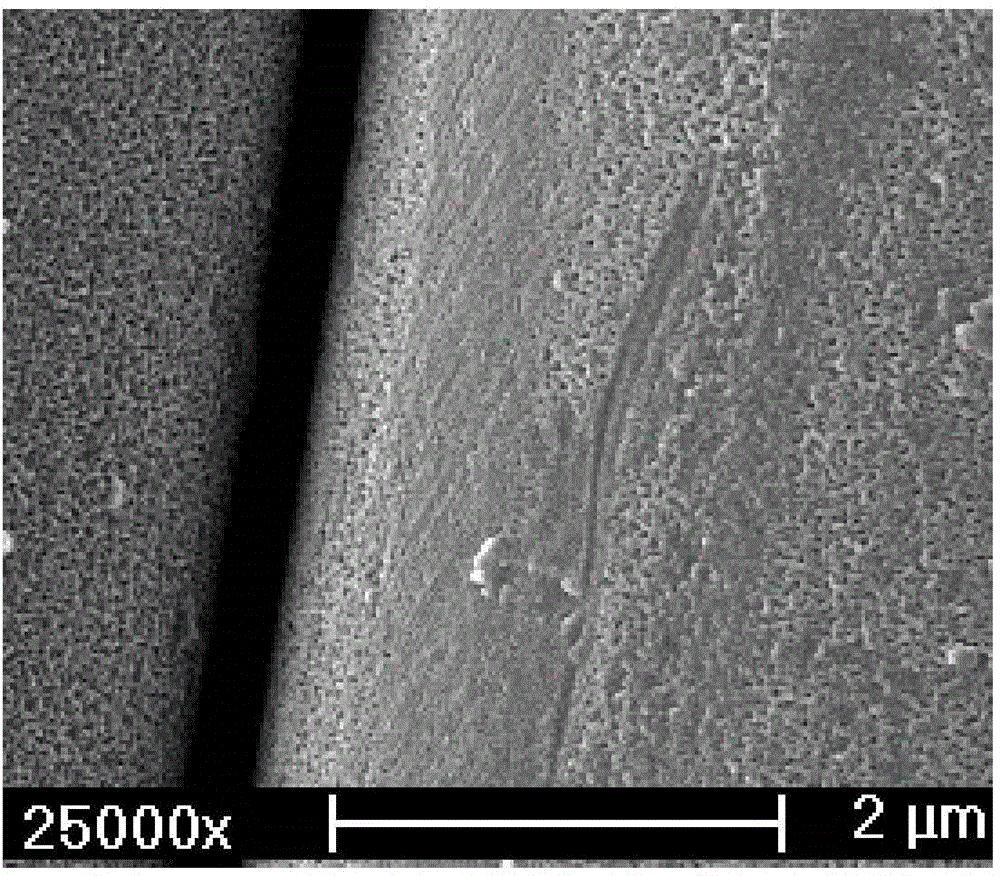

[0017] Weigh 3.16g of potassium permanganate, 12.37g of boric acid and 1.73g of manganese acetate, dissolve them in 20ml, 10ml and 10ml of deionized water respectively, add the boric acid solution and manganese acetate solution to the potassium permanganate solution in sequence. Then the mixed solution was transferred to a hydrothermal reaction kettle, the hydrothermal reaction temperature was 120°C, and the reaction time was 12h. After the reaction, the reaction product was washed with ethanol and deionized water, and dried under vacuum at 80° C. for 12 hours. By adding carbon fiber cloth during the hydrothermal reaction, boron-doped MnO 2 directly deposited on carbon fiber cloth to prepare flexible composite supercapacitor electrodes. figure 1 It is the XRD pattern of the composite electrode, and the manganese oxide material is birnessite-MnO 2 . figure 2 It is the SEM picture of the composite electrode, it can be seen that MnO 2 3D network surface structure.

Embodiment 2

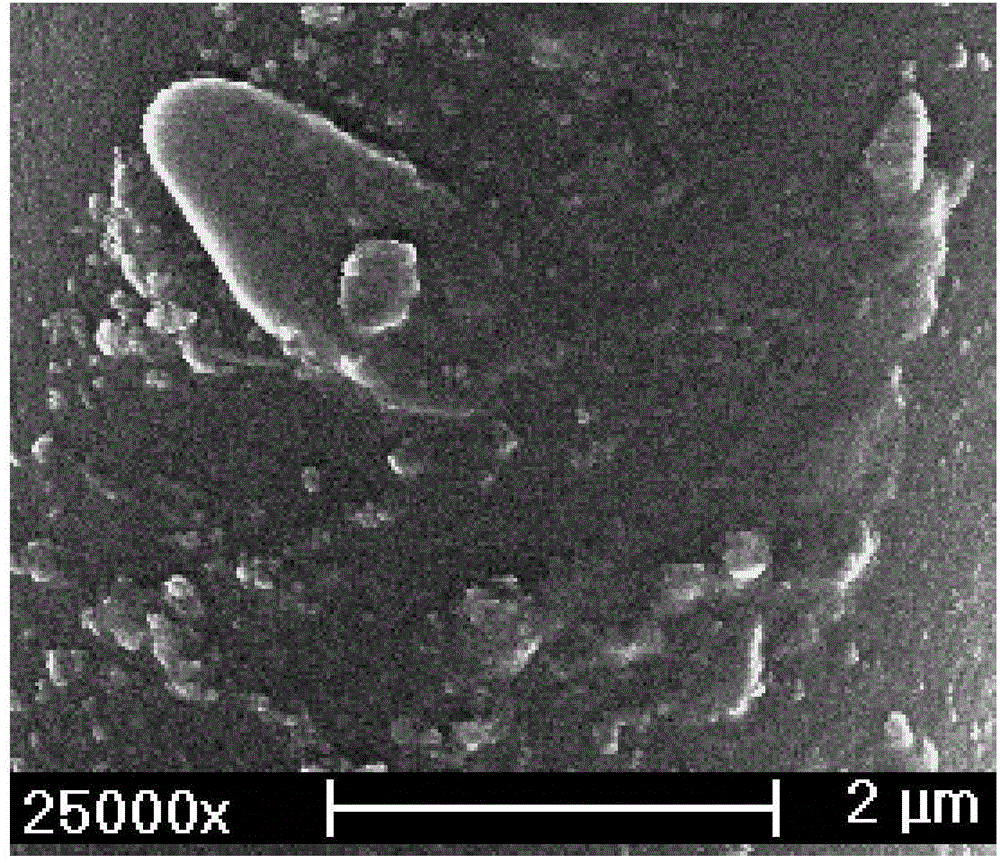

[0019] Weigh 3.16g of potassium permanganate, 0.00248g of boric acid and 1.73g of manganese acetate, dissolve them in 20ml, 10ml and 10ml of deionized water respectively, add the boric acid solution and manganese acetate solution to the potassium permanganate solution in sequence. Then the mixed solution was transferred to a hydrothermal reaction kettle, the hydrothermal reaction temperature was 120°C, and the reaction time was 12h. After the reaction, the reaction product was washed with ethanol and deionized water, and dried under vacuum at 80° C. for 12 hours. By adding carbon fiber cloth during the hydrothermal reaction, boron-doped MnO 2 directly deposited on carbon fiber cloth to prepare flexible composite supercapacitor electrodes. image 3 is the SEM image of the composite electrode. Compared with Example 1, the reduction of boron doping amount will obviously change the deposition method of manganese dioxide.

Embodiment 3

[0021] Weigh 3.16g of potassium permanganate, 2.48g of boric acid and 2.51g of manganese nitrate, dissolve them in 20ml, 10ml and 10ml of deionized water respectively, add the boric acid solution and manganese nitrate solution to the potassium permanganate solution in sequence. Then the mixed solution was transferred to a hydrothermal reaction kettle, the hydrothermal reaction temperature was 60° C., and the reaction time was 24 h. After the reaction, the reaction product was washed with ethanol and deionized water, filtered, and vacuum-dried at 60° C. for 24 hours.

[0022] Mix manganese dioxide, carbon black and polytetrafluoroethylene emulsion evenly in a mass ratio of 65:30:5, adjust it into a slurry, and evenly coat it on the foamed nickel, use a powder tablet press at a pressure of 15MPa Press down the tablet, and then put the electrode sheet into a vacuum oven at 120°C for 24 hours to vacuum dry. A saturated calomel electrode is used as a reference electrode, a 2×2 pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com