Doped Li/Ni/Mn/O material and preparation method thereof as well as lithium ion battery

A lithium-nickel-manganese-oxygen and atomic technology, which is applied in the field of doped lithium-nickel-manganese-oxygen materials and its preparation, can solve the problems of affecting lithium deintercalation and deintercalation of batteries, large usage of doping materials, and affecting the capacity of active materials, etc., to achieve effective It is beneficial to the performance of the battery, reduces the direct contact area, and improves the effect of electrochemical activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

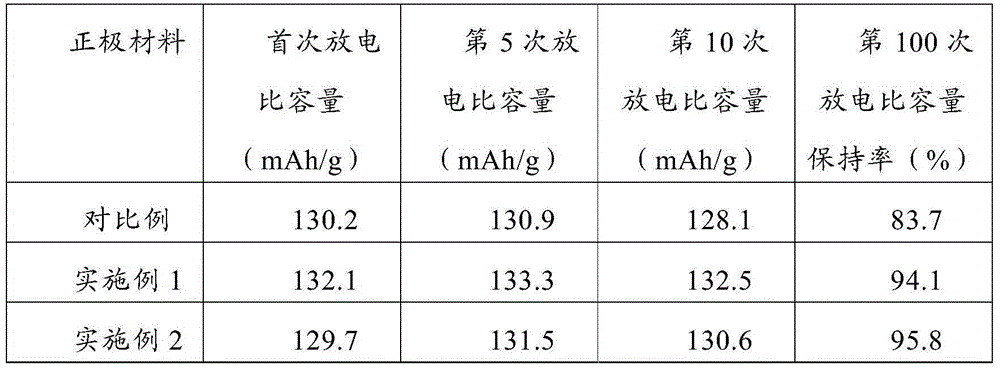

Examples

Embodiment 1

[0033] This embodiment provides a kind of doped lithium nickel manganese oxygen LiNi 0.5 mn 1.5 o 4 The preparation method of material, it comprises the following steps:

[0034] (1) First disperse 0.15g of chromium sulfate in a mixed solution of 100ml of ethanol and distilled water (the volume ratio of ethanol to distilled water is 4:1), after the chromium sulfate is fully dissolved, then add 9.85g of LiNi 0.5 mn 1.5 o 4 Material. After ultrasonic dispersion for 1 hour, heat and stir in a water bath at 85° C. for 4 hours, filter to obtain a solid powder, dry the solid powder and grind to obtain a precursor powder.

[0035] (2) The precursor powder was heated to 900°C for 18 hours at a heating rate of 5°C / min, and then annealed at 600°C for 12 hours at a cooling rate of 10°C / min. Naturally cooled to room temperature, after grinding and pulverizing, lithium nickel manganese oxide LiNi doped with chromium can be obtained 0.5 mn 1.5 o 4 Material.

[0036] In the present...

Embodiment 2

[0041] This embodiment provides a kind of doped lithium nickel manganese oxygen LiNi 0.5 mn 1.5 o 4 The preparation method of material, it comprises the following steps:

[0042] (1) First disperse 0.10g of aluminum nitrate in a mixed solution of 150ml of ethanol and distilled water (the volume ratio of ethanol to distilled water is 1:1), after the aluminum nitrate is fully dissolved, then add 19.90g of LiNi 0.5 mn 1.5 o 4 Material. After ultrasonic dispersion for 4 hours, heating and stirring in a water bath at 55° C. for 12 hours, filtering to obtain a solid powder, drying the solid powder and grinding to obtain a precursor powder.

[0043] (2) After the precursor powder is dried, it is heated to 950°C for 10 hours at a heating rate of 10°C / min and calcined for 10 hours; finally, it is annealed at a cooling rate of 5°C / min to 550°C for 6 hours. Cool naturally to room temperature, grind and pulverize to obtain doped lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 ...

Embodiment 3

[0049] This embodiment provides a kind of doped lithium nickel manganese oxygen LiNi 0.5 mn 1.5 o 4 The preparation method of material, it comprises the following steps:

[0050] (1) First disperse magnesium sulfate in ethanol solution, the concentration of magnesium sulfate in ethanol solution is 80mM, then add LiNi 0.5 mn 1.5 o 4 Material. LiNi 0.5 mn 1.5 o 4 The specific surface area of the material is 0.2m 2 / g, the particle size is 3 μm. The sound intensity is 30W / cm 2 After ultrasonic dispersion for 4 hours, heat and stir in a water bath at 120° C. for 2 hours, filter to obtain a solid powder, dry the solid powder and grind to obtain a precursor powder.

[0051] (2) Burn the precursor powder at 800°C for 2 hours, grind and pulverize, and obtain doped lithium nickel manganese oxide LiNi 0.5 mn 1.5 o 4 Material, the lithium nickel manganese oxide material LiNi doped with magnesium 0.5 mn 1.5 o 4 The content of the metal magnesium atoms in the is 0.1wt%. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com