Non-ferrous smelting waste acid purification treatment method

A purification treatment, non-ferrous metal technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that gypsum slag storage occupies a large amount of land resources and is difficult to stabilize Disadvantages such as standard discharge and high concentration of calcium ions in the effluent achieve the effect of reducing the possibility of scaling, stable treatment effect and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The polluted acid used in this example comes from Plant A and Plant B. However, the acidity of the polluted acid in the two plants differs greatly, and the F content is lower than the standard level. Therefore, the acidity and F content were adjusted first.

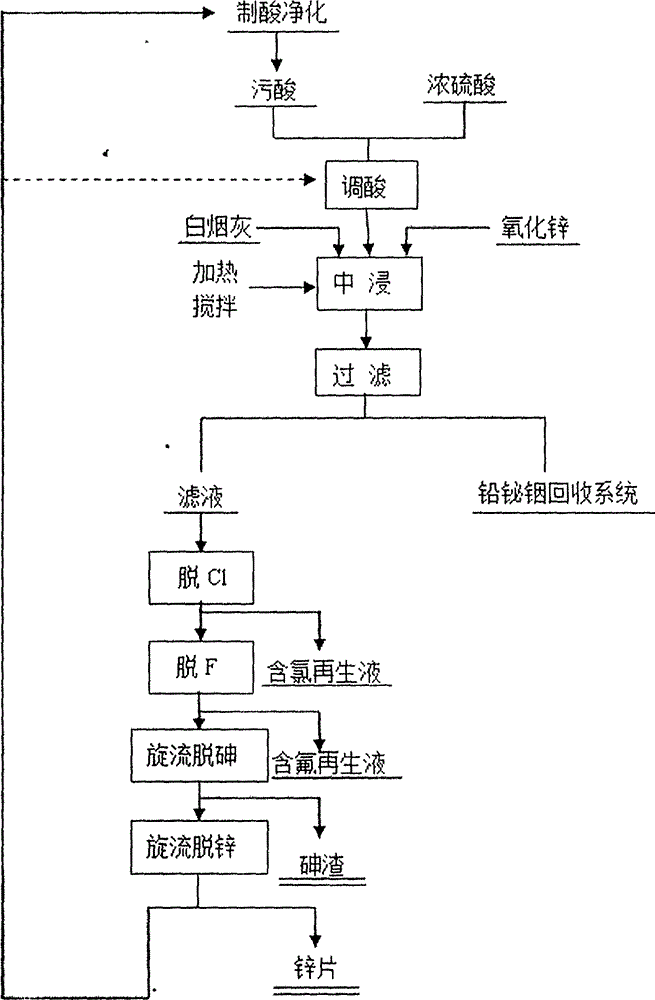

[0021] (1) Acid adjustment and middle immersion

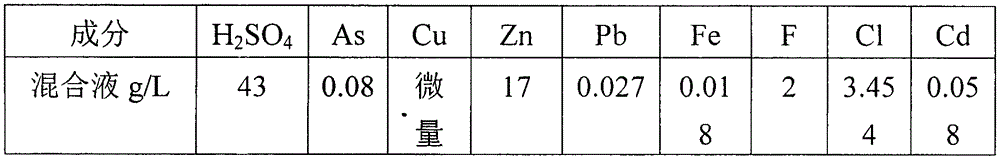

[0022] ①Mix the polluted acid from Plant A and Plant B at a volume ratio of 2:1 to make the acidity of the treated polluted acid more typical, then add 60mL of concentrated sulfuric acid until the acidity of the solution is 43g / L, and at the same time add 8.8 g NaF, so that the F content is more in line with the F content of typical polluted acid; see the following table for the content of each component after mixing:

[0023]

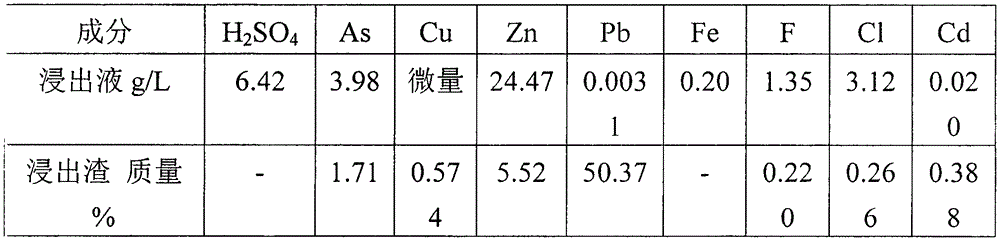

[0024] ② Add 100g of white soot and leach for 1 hour at a temperature of 70-80°C. Keep the temperature stable and then gradually add ZnO to adjust the acidity of the solution to a pH value of 2.5-3.0. When the pH value does not change, st...

Embodiment 2

[0050] This embodiment is to investigate the situation of using the liquid after electrowinning and impurity removal in Embodiment 1 to continue the swirling electrowinning and electrowinning zinc.

[0051] The content of zinc in the solution after electrodeposition and impurity removal is low, and zinc sulfate is added to prepare zinc sulfate solutions with zinc content of 50g / L and 100g / L respectively.

[0052]Clean the equipment with clean water, then inject 3L of zinc sulfate solution into the electrolyte storage tank, start the magnetic pump, and circulate the solution for 5 minutes; the swirl electrodeposition parameter takes the solution circulation volume of 600L / hr, and sets the current density for the electrodeposition experiment . During the test, the voltage was recorded at intervals during electrolysis, and the average cell voltage was calculated; the acidity of each time period was analyzed, and the records of the entire experiment process are shown in Table 1: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Removal rate | aaaaa | aaaaa |

| Removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com