Adhesive reinforcing agent for building inorganic coating material and preparation method of adhesive reinforcing agent

A bonding enhancer, inorganic coating technology, applied in the field of building materials, to improve the microstructure, improve the density and mechanical properties, high mechanical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

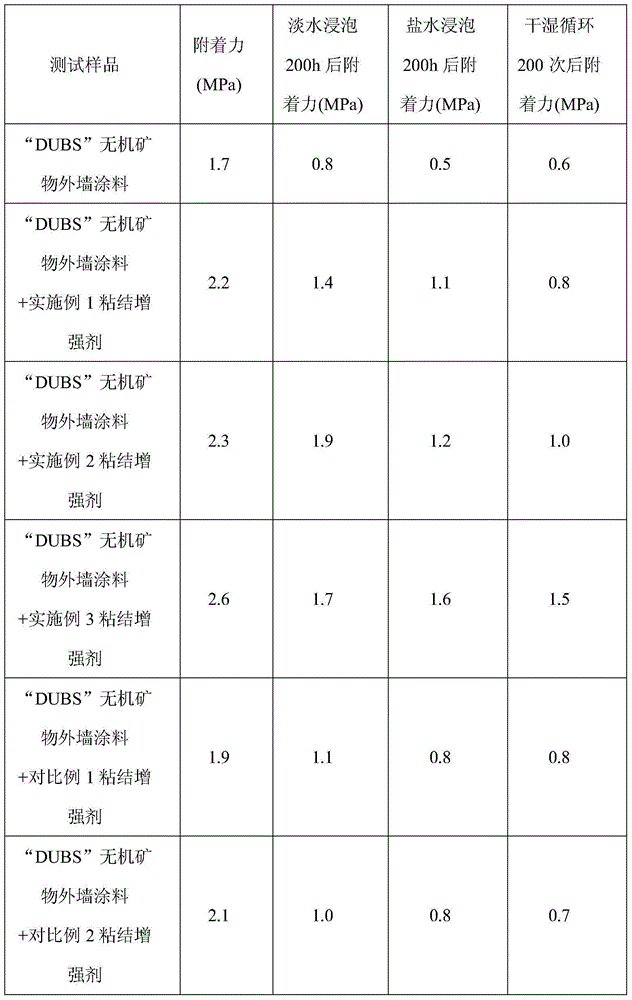

Examples

Embodiment 1

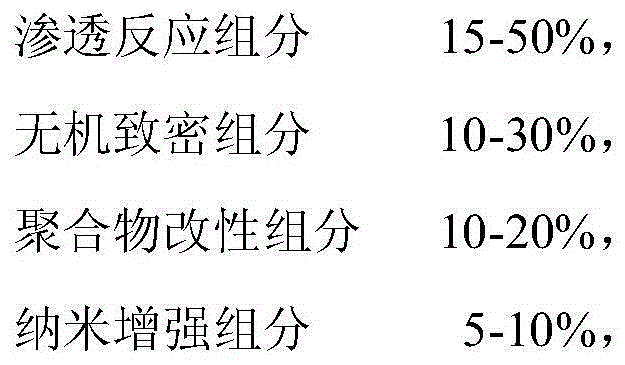

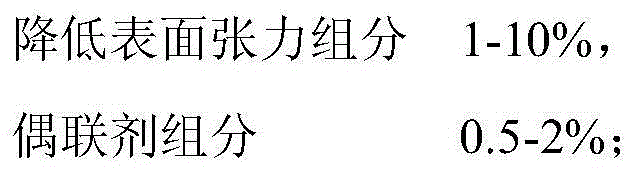

[0029] A kind of preparation method of the bonding enhancer of inorganic coating material for building, it comprises the steps:

[0030] Osmotic reaction components: industrial grade sodium metasilicate, 40%;

[0031] Inorganic dense components: industrial grade calcium hydroxide and gypsum, 30%;

[0032] Polymer modification component: vinyl acetate and ethylene copolymer powder (VAC / E), 10%;

[0033] Nano reinforcement component: industrial grade nano silica, 10%;

[0034] Surface tension reducing component: sodium stearate, 10%;

[0035] Coupling agent component: silane coupling agent SI-69 (Degoza, Germany), 0.5%.

[0036] Preparation method: First, weigh the osmotic reaction component, inorganic dense component, polymer modification component, nano-reinforcement component, surface tension reduction component and coupling agent component according to the above mass percentage; secondly, weigh the The above material components are ground to a particle size of less than ...

Embodiment 2

[0038] A kind of preparation method of the bonding enhancer of inorganic coating material for building, it comprises the steps:

[0039] Osmotic reaction components: industrial grade sodium metasilicate and industrial grade sodium tripolyphosphate, 50%;

[0040]Inorganic dense components: activated alumina and cement, 30%;

[0041] Polymer modification component: acrylate and styrene copolymer powder (A / S), 10%;

[0042] Nano reinforcement components: industrial grade nano calcium carbonate and industrial grade nano titanium dioxide, 5%;

[0043] Surface tension reducing component: sodium dodecylbenzenesulfonate, 5%;

[0044] Coupling agent component: aluminate coupling agent DL-411 (Huanrui Plastic Additives Co., Ltd., Shunde District, Foshan City), 1%.

[0045] Preparation method: First, weigh the osmotic reaction component, inorganic dense component, polymer modification component, nano-reinforcement component, surface tension reduction component and coupling agent compo...

Embodiment 3

[0047] A kind of preparation method of the bonding enhancer of inorganic coating material for building, it comprises the steps:

[0048] Osmotic reaction components: industrial grade sodium tetraborate and industrial grade sodium aluminate, 40%;

[0049] Inorganic dense components: industrial grade gypsum and slag, 15%;

[0050] Polymer modification components: vinyl acetate and higher fatty acid vinyl ester (VAC / VEOVA) and polyvinyl alcohol 0588, 15%;

[0051] Nano reinforcement components: industrial grade nano alumina and calcium carbonate whiskers, 3%;

[0052] Surface tension reducing component: triisopropanolamine, 7%;

[0053] Coupling agent component: titanate coupling agent JTW-131 (Nanjing Jingtianwei Chemical Co., Ltd.), 2%.

[0054] Preparation method: First, weigh the osmotic reaction component, inorganic dense component, polymer modification component, nano-reinforcement component, surface tension reduction component and coupling agent component according to t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com