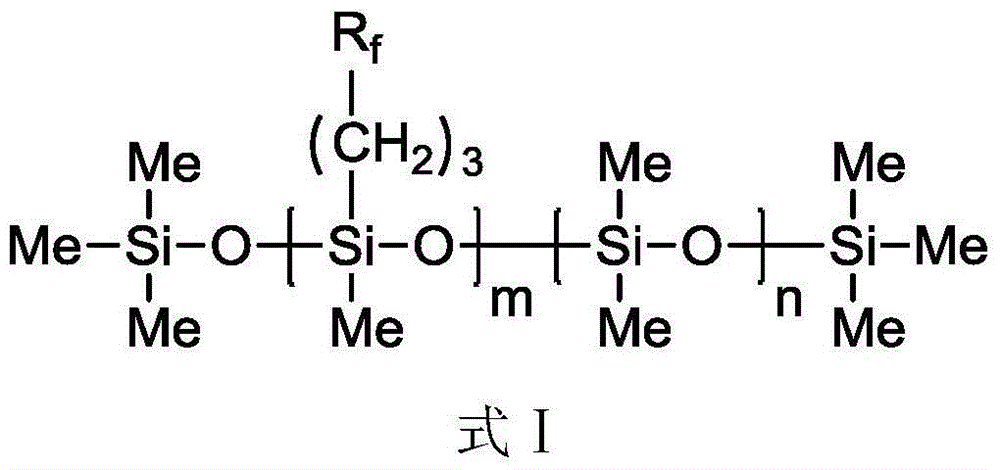

Fluoride-containing silicone oil defoamer and preparation method thereof

A technology of fluorine-containing silicone oil and defoamer, which is applied in the direction of foam dispersion/prevention to achieve the effects of suppressing foam, simple process flow, increasing high temperature resistance and chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

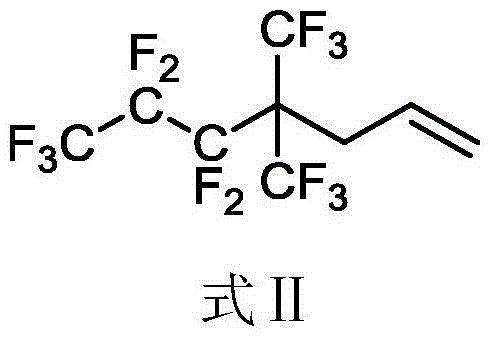

[0041] (1) Put 60g of hexafluoropropylene dimer and 23.2g of potassium fluoride into a three-necked flask with a reflux condensing device, then add 30mL of anhydrous DMF, heat to 60°C under stirring, and then add 24g of allyl bromide with The dropping funnel was added dropwise into the reaction bottle, and the dropwise addition was completed in 1.0 hour. After continuing to react at constant temperature for 26 hours, cool to room temperature, add 300 mL of water to the reaction solution, extract three times with 300 mL of ether, combine the organic phases, and separate the organic phases by rectification to obtain 50.0 g of fluorine-containing olefins with a yield of 68%.

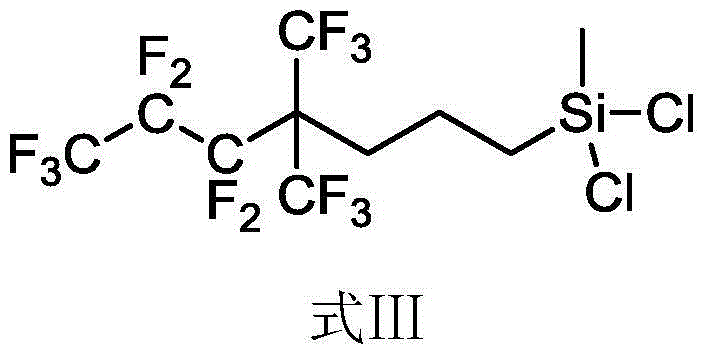

[0042] (2) Add 120 g of fluorine-containing olefin into a 250 mL autoclave, and then add Karstede catalyst into the autoclave. The amount of Karstede catalyst used is 30 ppm of the mass of methyldichlorosilane. Seal the reaction kettle, start stirring and heating, so that the temperature of the reaction ket...

Embodiment 2

[0046] (1) Put 60g of hexafluoropropylene dimer and 23.2g of potassium fluoride into a three-necked flask with a reflux condensing device, then add 30mL of anhydrous DMF, heat to 50°C under stirring, and add 31.2g of allyl bromide Add it dropwise into the reaction bottle with a dropping funnel, and the dropwise addition is completed in 1.0 hour. After continuing to react at constant temperature for 29 hours, cool to room temperature, add 300 mL of water to the reaction solution, extract three times with 300 mL of ether, combine the organic phases, and separate the organic phases by rectification to obtain 46.8 g of fluorine-containing olefins with a yield of 65%.

[0047] (2) Add 120 g of fluorine-containing olefins into a 250 mL autoclave, and then add Karstede catalyst into the autoclave. The amount of Karstede catalyst used is 10 ppm of the mass of methyldichlorosilane. Seal the reaction kettle, start stirring and heating, so that the temperature of the reaction kettle rise...

Embodiment 3

[0051] (1) Put 60g of hexafluoropropylene dimer and 23.2g of potassium fluoride into a three-necked flask with a reflux condensing device, then add 30mL of anhydrous DMF, heat to 80°C under stirring, and add 20.4g of allyl bromide Add it dropwise into the reaction bottle with a dropping funnel, and the dropwise addition is completed in 1.0 hour. After continuing to react at constant temperature for 19 hours, cool to room temperature, add 300 mL of water to the reaction solution, extract three times with 300 mL of ether, combine the organic phase, and separate the organic phase by rectification to obtain 36.4 g of the product fluorine-containing olefin, with a yield of 60%.

[0052] (2) Add 120 g of fluorine-containing olefin into a 250 mL autoclave, and then add Karstede catalyst into the autoclave. The amount of Karstede catalyst used is 50 ppm of the mass of methyldichlorosilane. Seal the reaction kettle, start stirring and heating, so that the temperature of the reaction ke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com