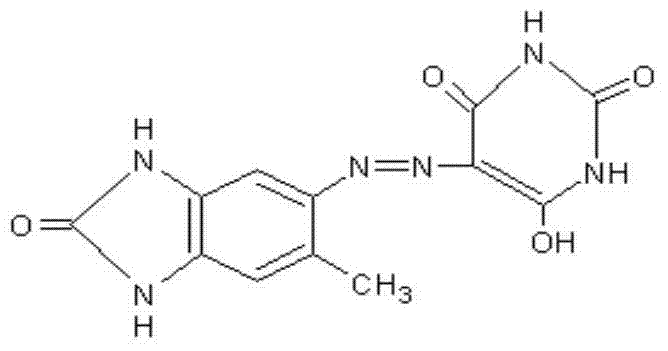

Preparation method for pigment orange 64 with high color intensity

A coloring strength, pigment orange technology, applied in chemical instruments and methods, azo dyes, organic dyes, etc., can solve the problems of physical and mental health injuries of operators, different product particle states, and increased sewage treatment costs, and shorten the reaction time The effect of time, excellent dispersibility, and soft particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

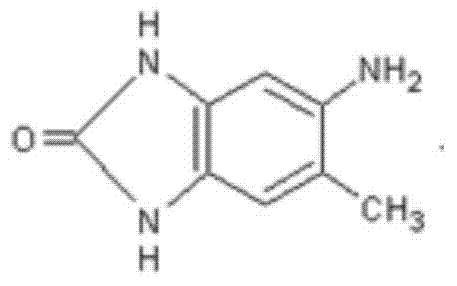

[0038] 190kg of 5-amino-6-methylbenzimidazolone, 414kg of hydrochloric acid with a concentration of 30% by mass and 1850kg of water were stirred and beaten, added 1000kg of ice to cool to 0-5°C, and 199kg of nitrous acid with a concentration of 40% by mass was added The sodium solution is diazotized, and the diazo end eliminates excess sodium nitrite to obtain a diazonium salt solution.

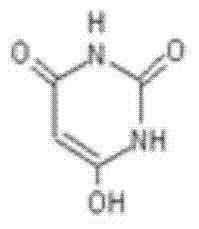

[0039] 148 kg of barbituric acid was dissolved in 185.7 kg of 30% sodium hydroxide aqueous solution and 2000 kg of water, and the temperature was adjusted to 15° C. to obtain a coupling solution.

[0040] Add the diazonium salt solution and the coupling solution to the buffer solution at the same time for reaction. The buffer solution is prepared from 2000kg water, 2kg emulsifier FM, and 100kg sodium acetate; the pH value of the coupling is 7, and the temperature is raised to 90 ° C. hours, filtered to obtain crude pigment filter cake.

[0041] Add 842.8kg of crude pigment filter cake with a...

Embodiment 2

[0043] 190kg of 5-amino-6-methylbenzimidazolone, 425kg of hydrochloric acid with a concentration of 30% by mass and 1850kg of water were stirred and beaten, added 1000kg of ice to cool to 0-5°C, and 200kg of nitrous acid with a concentration of 40% by mass was added The sodium solution is diazotized, and the diazo end eliminates excess sodium nitrite to obtain a diazonium salt solution.

[0044] 150kg of barbituric acid was dissolved in 185.7kg of 30% sodium hydroxide aqueous solution and 2000kg of water, and the temperature was adjusted to 15°C to obtain a coupling solution.

[0045] Add the diazonium salt solution and the coupling solution to the buffer solution for reaction at the same time. The buffer solution is prepared from 2000kg water, 2kg emulsifier OP-10, and 100kg sodium acetate. The pH value of the coupling is 6.5, and the temperature is raised to 90°C. Keep warm for 2 hours, filter to obtain crude pigment filter cake.

[0046]Add 846.8kg of crude pigment filter ...

Embodiment 3

[0048] 190kg of 5-amino-6-methylbenzimidazolone, 414kg of hydrochloric acid with a concentration of 30% by mass and 1850kg of water were stirred and beaten, added 1000kg of ice to cool to 0-5°C, and 199kg of nitrous acid with a concentration of 40% by mass was added The sodium solution is diazotized, and the diazo end eliminates excess sodium nitrite to obtain a diazonium salt solution.

[0049] 148kg of barbituric acid was dissolved in 185.7kg of 30% sodium hydroxide aqueous solution and 2000kg of water, and the temperature was adjusted to 15°C to obtain a coupling solution.

[0050] The diazonium salt solution and the coupling solution are simultaneously added to the buffer solution for reaction. The buffer solution is prepared from 2000kg water, 2kg flat plus O, 100kg sodium bicarbonate and 50kg sodium acetate. The pH value of the coupling is 7, and the temperature is raised to Heat at 90°C for 2 hours and filter to obtain a filter cake of crude pigment.

[0051] 843.5kg o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com