Carbon-deposition-resistant catalytic cracking catalyst and preparation method thereof

A catalytic cracking and catalyst technology, which is applied in the fields of chemical industry and catalytic cracking, can solve the problems of deteriorating product distribution, reducing conversion rate, affecting catalyst activity, etc., to reduce the probability of condensation coking, improve the anti-coking ability, and enhance the bonding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] This embodiment provides an anti-coking catalytic cracking catalyst, wherein the catalyst is prepared through the following steps:

[0049] 1. Preparation of SAPO-11 molecular sieves with different fluorine contents:

[0050] Al 2 o 3 ,P 2 o 5 , SiO 2 , The molar ratio of di-n-propylamine is 1:1:0.4:1 and mixed with deionized water evenly;

[0051] Under stirring conditions, add hydrofluoric acid, mix evenly, adjust the pH value to 4.5-5.5, and obtain a solution with a pH value of 4.5-5.5;

[0052] The solution with a pH value of 4.5-5.5 was prepared in a water bath at 80°C to prepare dry glue, and the dry glue was dried at 80°C for 45 minutes;

[0053] crystallizing the dried dry glue at 200° C. for 24 hours to obtain a crystallized product;

[0054] The crystallized product was washed with deionized water, dried at 100° C. for 12 hours, and then calcined at 600° C. for 4 hours to obtain a fluorine-containing SAPO-11 molecular sieve.

[0055] The above-mentioned ...

Embodiment 2

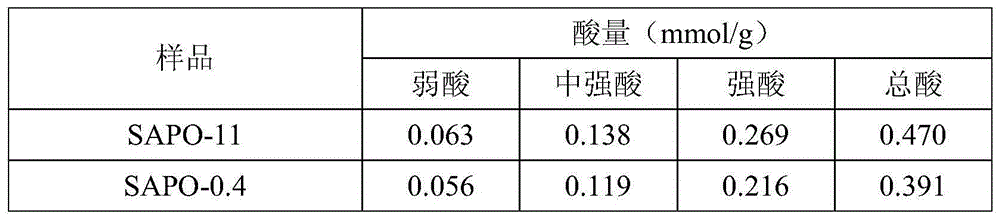

[0065] This example provides a comparison of the acidity of the SAPO-11 molecular sieve and the fluorine-containing SAPO-11 molecular sieve (SAPO-0.4) prepared in Example 1, which was tested by the ammonia gas temperature-programmed desorption method.

[0066] The acid content and acid strength of the sample were analyzed by CHEMBET3000TPR / TPD chemical adsorption instrument produced by Quantanchrome Company of the United States. After the sample was treated at 600 ° C for 0.5 h in a He atmosphere, it was cooled to 100 ° C and adsorbed NH 3 , starting from 100°C for 10min after adsorption saturation -1 Program the temperature to 650°C to start the desorption test.

[0067] The test results of the ammonia temperature programmed desorption method are shown in Table 1.

[0068] Table 1

[0069]

[0070] SAPO-0.4: In the process of preparing fluorine-containing SAPO-11 molecular sieve, the amount of hydrofluoric acid added is calculated by HF, HF and Al 2 o 3 The molar ratio...

Embodiment 3

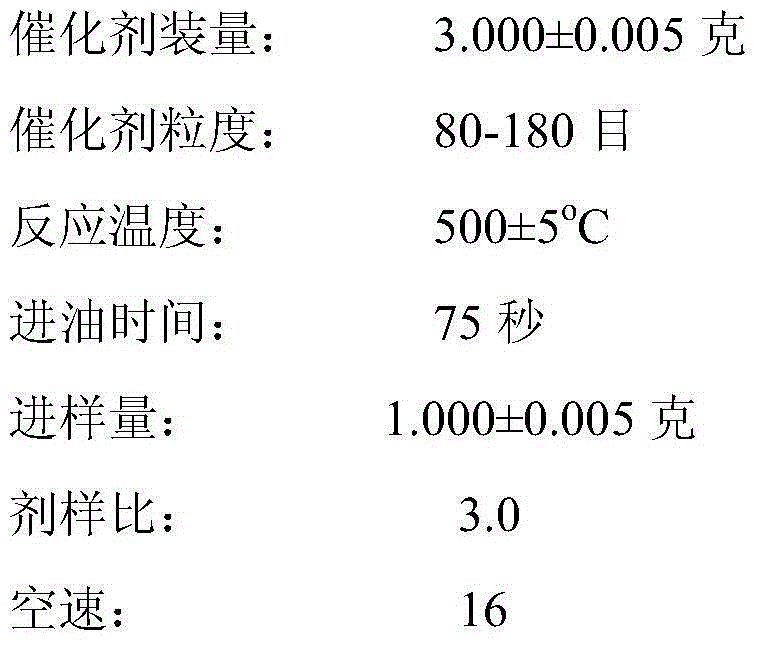

[0076] This example provides the application of the anti-coking catalytic cracking catalyst prepared in Example 1 in the catalytic cracking of n-dodecane.

[0077] The reaction conditions for catalytic cracking of n-dodecane are:

[0078]

[0079] The product distribution of above-mentioned n-dodecane catalytic cracking reaction is as shown in table 2:

[0080] Table 2

[0081] catalyst

Y / SAPO-0

Y / SAPO-0.2

Y / SAPO-0.4

Y / SAPO-0.6

Y / SAPO-0.8

Hydrogen / %

0.01

0.01

0.01

0.01

0.01

Dry gas / %

0.46

0.38

0.33

0.34

0.29

LPG / %

24.05

21.07

20.17

19.76

19.38

i-C 5-12 / %

9.27

8.89

11.88

10.13

7.38

C 5-12 = Olefin / %

6.54

6.53

7.09

6.42

6.05

Aromatics / %

1.59

0.93

1.83

1.04

0.88

Naphthenic / %

0.24

0.26

0.37

0.25

0.23

Coke / %

0.36

0

0

0

0

i-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com