Polyamide five-layer co-extrusion composite film and preparation method thereof

A technology of co-extruded composite film and polyamide, which is applied in the field of polyamide five-layer co-extruded composite film and its preparation, can solve the problems of not meeting the barrier property requirements of solar cell modules, poor moisture and heat aging resistance, and difficulty in overcoming water absorption, etc. , to achieve good mechanical properties, resistance to system voltage, and low moisture absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

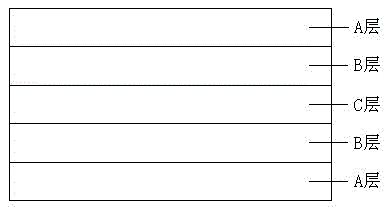

[0023] see figure 1 , extracting a polyamide five-layer co-extrusion composite film, including A layer, B layer and C layer, from top to bottom are A layer, B layer, C layer, B layer and A layer. The five layers are all based on modified polyamide, which meets the basic properties of high insulation, system voltage resistance, high dimensional stability, and thermal stability. Among them, layer A is a high weather resistance layer, adding nano-scale materials with anti-aging, anti-ultraviolet and improving mechanical properties to the modified polyamide to meet the requirements of high weather resistance; layer B is a high barrier layer, adding nano-scale materials to the modified polyamide The water-blocking and gas-blocking material is controlled by the production process and forms a closed-loop structure through molecular interlocking to achieve a high barrier effect; the C layer is a modified PA substrate layer.

[0024] A method for preparing a polyamide five-layer co-ex...

Embodiment 2

[0028] Provide a kind of preparation method of polyamide five-layer co-extruded composite film, the structure of the obtained polyamide five-layer co-extruded composite film is the same as that of Example 1, comprising the steps of:

[0029] (1) Add 200 g of octamethylcyclotetrasiloxane, 200 g of methylphenylcyclotetrasiloxane, 18.64 g of epoxy end-capping agent and tetramethylammonium hydroxide into a 1L clean three-neck flask under nitrogen protection Alkali glue 8g, polymerized at 100°C for 4 hours, decomposed the catalyst at 140°C for 1 hour, and then decompressed to remove the low molecular weight to obtain epoxy-terminated methylphenylpolysiloxane with a viscosity of 590mpa·s. Then take 40 g of the obtained epoxy-terminated methylphenyl polysiloxane and 360 g of polyamide 66 (PA66), heat to 160° C., and react under reduced pressure for 4 hours to obtain 400 g of silicone-modified polyamide.

[0030] (2) Add 200 g of the obtained silicone-modified polyamide, 20 g of nano-...

Embodiment 3

[0032] Provide a kind of preparation method of polyamide five-layer co-extruded composite film, the structure of the obtained polyamide five-layer co-extruded composite film is the same as that of Example 1, comprising the steps of:

[0033] (1) Add 200 g of octamethylcyclotetrasiloxane, 200 g of octaphenylcyclotetrasiloxane, 18.64 g of epoxy end-capping agent, tetramethylammonium hydroxide base, and Glue 8g, polymerized at 100°C for 4 hours, decomposed the catalyst at 140°C for 1 hour, and then decompressed to remove low molecular weight, and obtained epoxy-terminated dimethyl-diphenylpolysiloxane with a viscosity of 780 mpa·s. Then take 40 g of the obtained epoxy-terminated dimethyl-diphenyl polysiloxane, and mix it with 360 g of polyamide 9 (PA9), heat it to 160° C., and react under reduced pressure for 4 hours to obtain 400 g of silicone-modified polyamide.

[0034] (2) 200 g of the obtained silicone-modified polyamide, 20 g of nano-zinc oxide with a particle size of 500 n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com