Preparation method of medical implant material surface function atom doped molecular sieve layer

A technology of implant materials and molecular sieves, which is applied in the field of preparation of molecular sieve coatings doped with functional atoms on the surface of medical implant materials, to achieve the effects of reduced release, little impact on mechanical properties, and improved cell compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 1g Silicalite-1 molecular sieve seed crystal and ultrasonically disperse it in 50mL aqueous solution to prepare a white seed crystal solution.

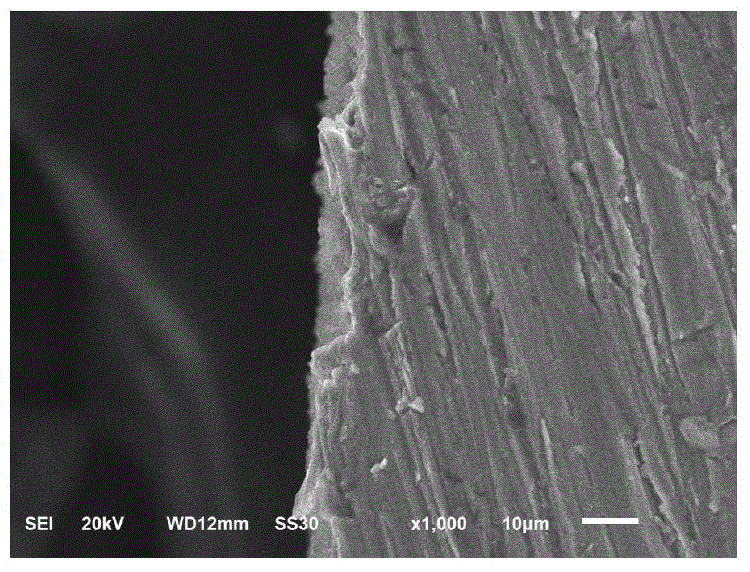

[0036] TiNb alloy (TiNb mass percentage 70%, Nb mass percentage 30%) was respectively placed in acetone, deionized water, ethanol, ultrasonic cleaning 10min, then soaked in 30wt% hydrogen peroxide solution for 30min, make the surface with more Hydroxyl groups were rinsed with a large amount of deionized water and dried with nitrogen gas.

[0037] The pretreated TiNb alloy material was immersed in the prepared seed crystal solution for 15 minutes, dried at room temperature, and placed in an oven at 110° C. for 2 hours.

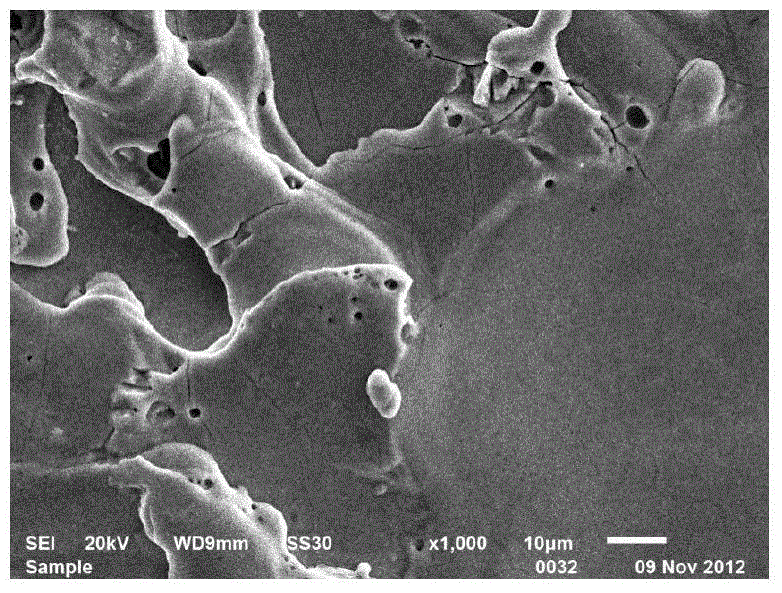

[0038] Mix and stir 0.22g tetrapropylammonium bromide, 0.042g potassium hydroxide, and 15mL deionized water evenly, then add 0.84mL tetraethyl orthosilicate and 0.025g calcium nitrate, and continue stirring for 12 hours to obtain a precursor solution. Two TiNb alloy discs (diameter 8mm, thickness 1mm) obt...

Embodiment 2

[0040] Mix and stir 0.38g tetrapropylammonium bromide, 0.03g potassium hydroxide, and 20mL deionized water evenly, then add 1mL tetraethyl orthosilicate and 0.02g zinc chloride, and continue stirring for 24h to obtain a precursor solution. Two TiNb alloy discs (diameter 8 mm, thickness 1 mm) pre-coated with seed crystals in Example 1 were fixed in a reaction kettle with a volume of 15 mL, 10 mL of precursor solution was added, and hydrothermal reaction was carried out at 150 °C for 24 h. After cooling to room temperature, ultrasonically clean them with deionized water and dry them, place them in a muffle furnace for calcination at 600°C for 0.5h, and heat up at a rate of 0.5°C / min. After natural cooling, the Silicalite-1 molecular sieve function doped with Zn atoms is obtained. Thin TiNb alloy material, the thickness of the coating is about 15μm.

Embodiment 3

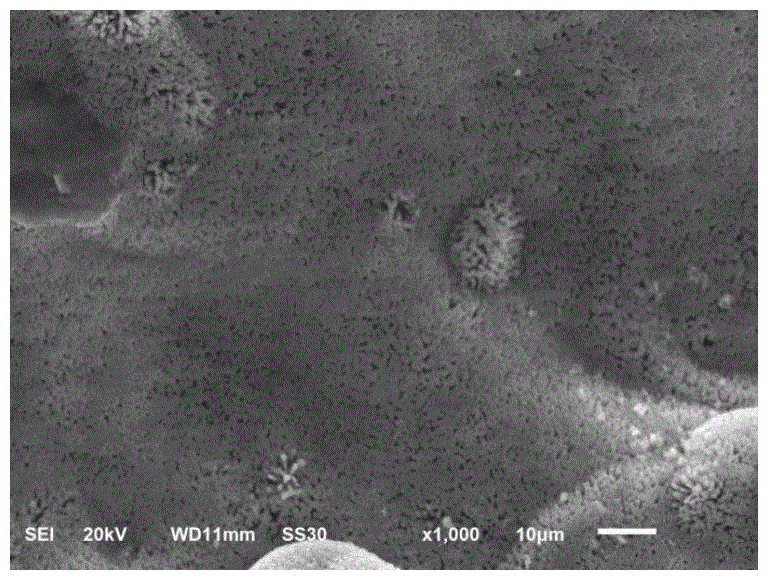

[0042] Mix and stir 0.1g tetrapropylammonium bromide, 0.05g potassium hydroxide, and 10mL deionized water evenly, then add 0.6mL tetraethyl orthosilicate and 0.023g magnesium acetate, and continue stirring for 5 hours to obtain a precursor solution. A TiNb alloy disc (diameter 8 mm, thickness 1 mm) pre-coated with seed crystals in Example 1 was fixed in a reaction kettle with a volume of 15 mL, 10 mL of precursor solution was added, and hydrothermal reaction was carried out at 230 ° C for 5 h. After cooling to room temperature, ultrasonically clean them with deionized water, dry them, and place them in a muffle furnace for calcination at 400°C for 6h with a heating rate of 2°C / min. After natural cooling, Mg atom-doped Silicalite-1 molecular sieve functionalized TiNb alloy material, the thickness of the coating is about 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com