Organic/gallium nitride heterogeneous p-n junction ultraviolet light detector and preparing method thereof

A technology of ultraviolet light and detectors, which is applied in the fields of organic semiconductor devices, semiconductor/solid-state device manufacturing, photovoltaic power generation, etc., can solve the problems of high manufacturing cost of ultraviolet light detectors, inability to be widely used, high difficulty in doping technology, etc., to achieve Excellent device performance, low price, and excellent photoelectric performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

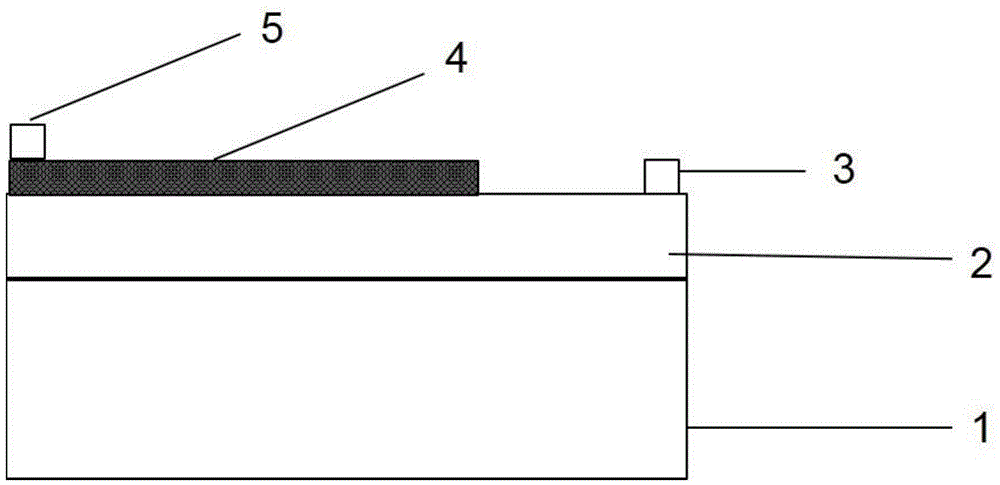

[0042] GaN films were grown by metal-organic vapor deposition, and NH 3 As a nitrogen source, trimethylgallium (TMGa) or triethylgallium (TEGa) is used as a gallium source, and the reaction temperature is higher than 900 degrees Celsius, and epitaxially grows a GaN film on a sapphire substrate. Afterwards, GaN was ultrasonically cleaned with acetone and ethanol, rinsed with deionized water and dried. The side electrodes are prepared by evaporating metal Ti / Al / Ni / Au on the GaN substrate with a specific thickness of 20nm / 120nm / 70nm / 100nm and annealing at 200°C / 585°C / 600°C / 885°C respectively . GaN is used as the working electrode, PT wire is used as the side electrode and the counter electrode, placed in the electrolyte (0.05mM pyrrole + 0.1mM sodium perchlorate aqueous solution), and the electrochemical deposition is performed by chronopotential method, and the current density is 0.1mA / cm 2 , the deposition time is 1.5h, so as to obtain the organic / GaN composite heterojunction...

Embodiment 2

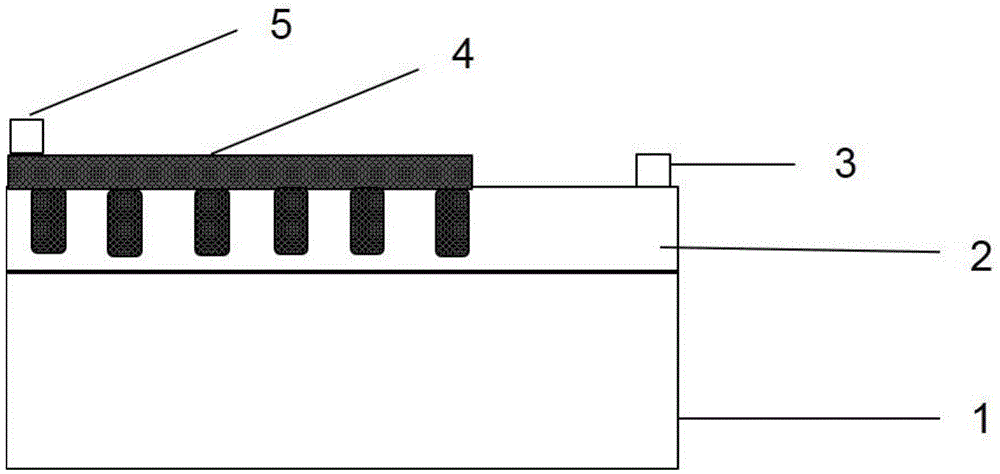

[0044] GaN films were grown by metal-organic vapor deposition, and NH 3As a nitrogen source, trimethylgallium (TMGa) or triethylgallium (TEGa) is used as a gallium source, and the reaction temperature is higher than 900 degrees Celsius, and epitaxially grows a GaN film on a sapphire substrate. The grown GaN thin film is etched by dry etching to obtain porous GaN, and then ultrasonically cleaned with acetone and ethanol, rinsed with deionized water and dried. The side electrodes are prepared by evaporating metal Ti / Al / Ni / Au on the GaN substrate with a specific thickness of 20nm / 120nm / 70nm / 100nm and annealing at 200°C / 585°C / 600°C / 885°C respectively . GaN is used as the working electrode, PT wire is used as the side electrode and the counter electrode, placed in the electrolyte (0.05mM pyrrole + 0.1mM sodium perchlorate aqueous solution), and the electrochemical deposition is performed by chronopotential method, and the current density is 0.1mA / cm 2 , the deposition time is 1.5...

Embodiment 3

[0046] GaN films were epitaxially grown on silicon carbide substrates by gas source molecular beam epitaxy, and the gas source was N 2 . Afterwards, the epitaxially grown GaN film was ultrasonically cleaned with acetone and ethanol, rinsed with deionized water and dried. Evaporated metal by electron beam on GaN substrate: Ni / Au, the thickness is 20 / 120nm respectively,

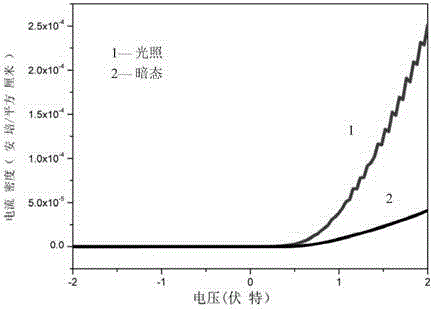

[0047] And the side electrode is prepared by high temperature annealing method at 600°C / 885°C. Using GaN as the working electrode, PT wire as the side electrode and the counter electrode, placed in the electrolyte (0.2M aniline + 0.5M sulfuric acid aqueous solution), the electrochemical deposition was carried out by chronoamperometry, where the voltage was 8V, and the deposition time was 2h. An organic / GaN composite heterojunction structure is obtained. Finally, silver paste is placed on the organic layer and annealed at 110 degrees Celsius for 20 minutes as an electrode material. The structure and performa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com