Method for low temperature aqueous solution electrochemical codeposition of nickel iridium alloy

An electrochemical and aqueous solution technology, applied in the field of nickel-iridium alloy preparation, can solve the problems of poor nickel-iridium alloy purity, influence on catalytic effect, etc., and achieve the effects of low cost, controllable alloy thickness and composition, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

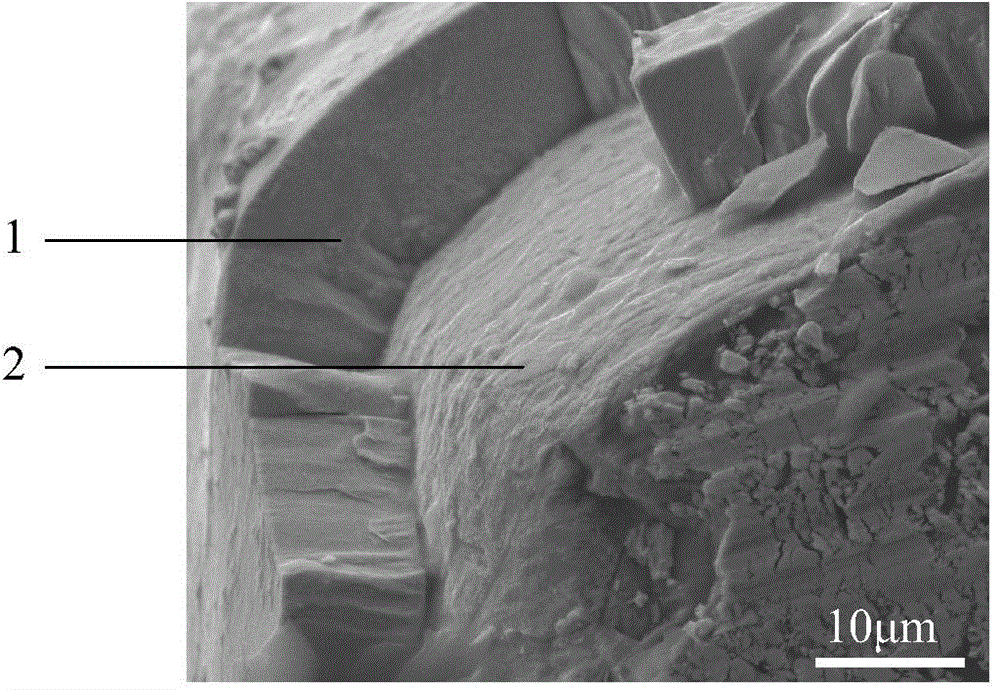

[0022] Such as figure 1 As shown, 1 is the nickel-iridium coating, and 2 is the base material of the workpiece. First configure 100mL electroplating solution iridium trichloride 0.01mol / L, nickel sulfate 0.005mol / L, nickel sulfamate 0.02mol / L, citric acid 0.350mol / L, saccharin 0.010mol / L, and import the weighed medicines 100mL glass container. First add about 70mL of deionized water to stir and dissolve; then add sodium hydroxide solution dropwise to adjust the pH to around 4.0, then add deionized water to 90mL, use a pH meter to measure the pH value of the plating solution, and then add a small amount of Sodium hydroxide was used to fine-tune the pH to 5.0. Use copper workpiece 2 as the substrate, first perform surface polishing and detergent cleaning, then perform nitric acid cleaning for 1 min, and then perform ultrasonic cleaning with acetone. The reference electrode is Ag / AgCl / saturated KCl, the anode is platinum, and the temperature of the water bath is adjusted to 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com