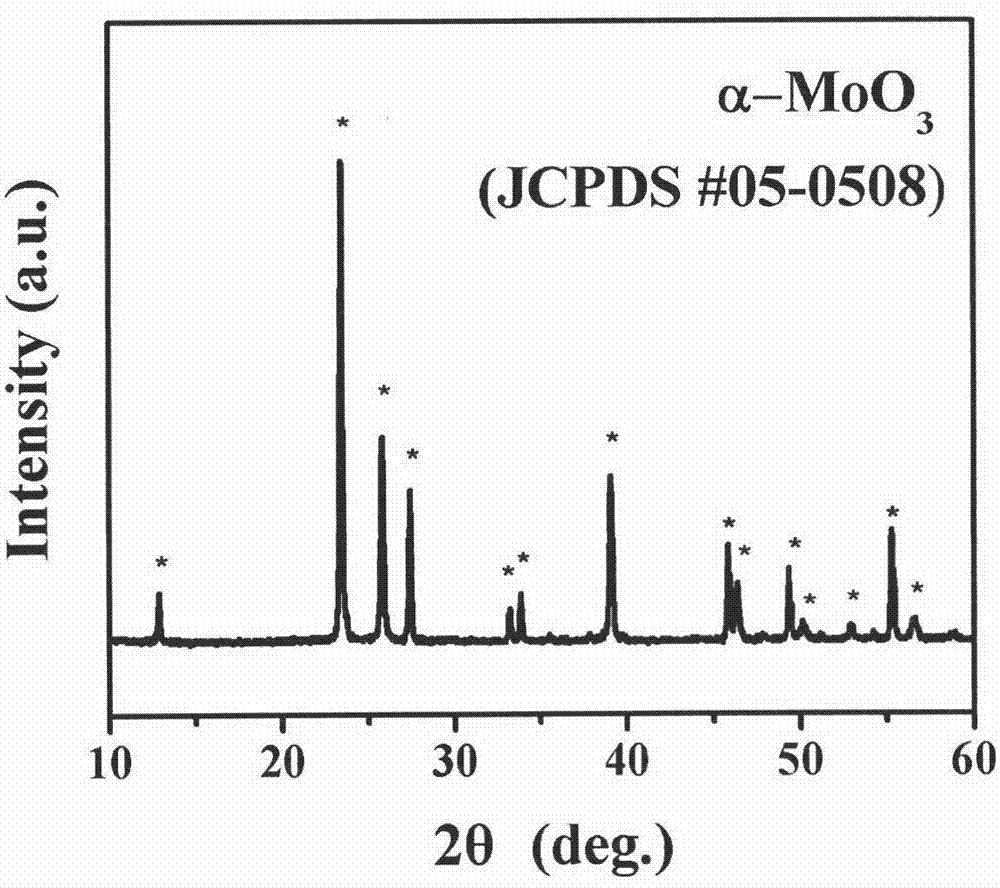

Method for preparing orthogonal-phase MoO3 monocrystal nanosheet through chemical vapor deposition

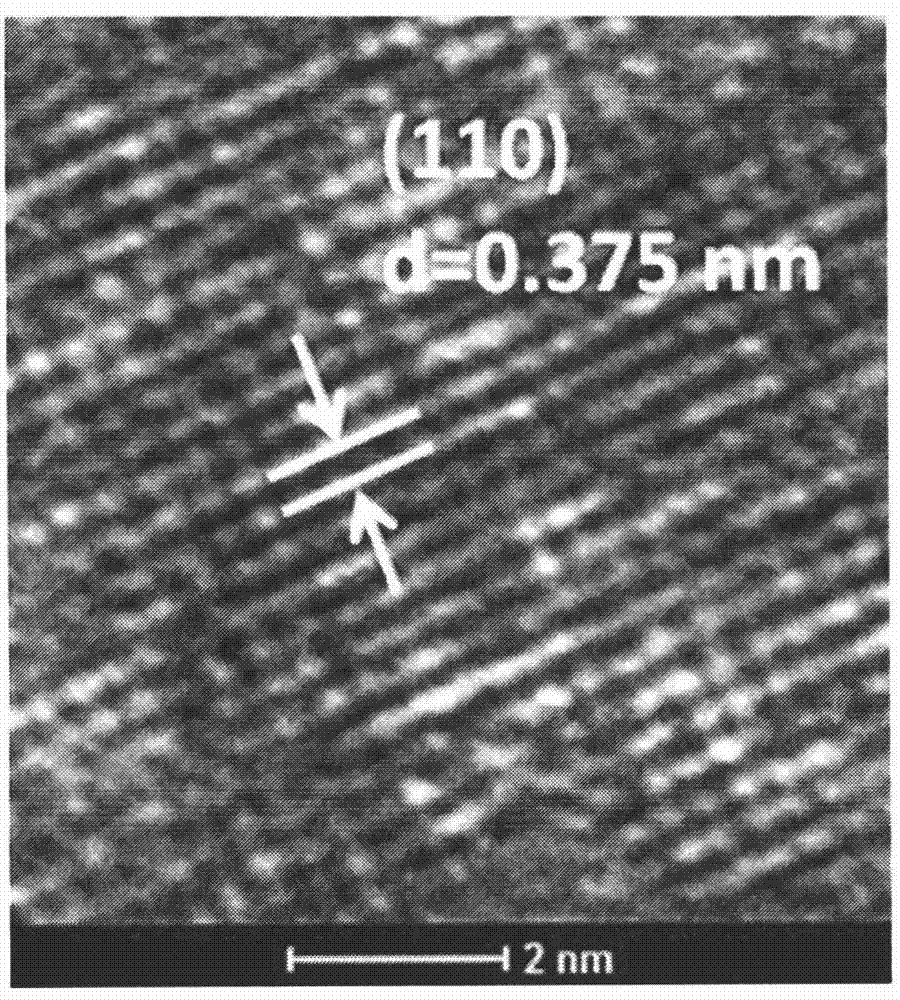

A chemical vapor deposition and single-crystal nanotechnology, which is applied in the field of nanomaterials, can solve the problem of liquid phase process safety and acidification operation is difficult to control, affecting the intrinsic physical properties of α-MoO nanocrystals, and the nanostructure morphology and size are not uniform, etc. problems, to achieve the effect of safe and non-toxic preparation process, superior crystallinity and single crystal quality, single raw material and equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] α-MoO 3 The preparation method of single crystal nanosheet comprises the following steps:

[0030] Step 1. Select a 2cm×3cm quartz plate as the sample deposition substrate, and clean the surface of the substrate before deposition and growth. The specific scheme is: put the substrate into acetone for 15 minutes, then put it into ethanol for 15 minutes, and finally clean it in ionized water for 10 minutes, take out the cleaned quartz substrate, and dry it with nitrogen.

[0031] Step 2. Take MoS 2 Put 0.2g of powder into the ceramic boat as a raw material, place the ceramic boat with the raw material in the quartz tube of the tube furnace, and place the cleaned quartz substrate on the downwind port of the ceramic boat (the carrier gas flows into the ceramic boat from the air inlet). , carrying the sublimated Mo gas source to the oxidation crystal at the substrate through the high-temperature ceramic boat, and the carrier gas is discharged from the other end of the gas o...

Embodiment 2

[0039] In the above step 5, the reaction temperature of the tube furnace is set at 600-700° C., and the holding time is 20 min. Other steps and details remain unchanged from Example 1.

[0040]The sample prepared in Example 2 is not a uniform orthorhombic cubic crystal system, but has monoclinic and hexagonal crystal systems, so MoO with a uniform orthorhombic cubic crystal phase cannot be formed at a reaction temperature lower than 700°C. 3 crystals.

Embodiment 3

[0042] In step 5 of embodiment 1, the reaction time of setting the tube furnace is 30-40min, and other steps and details remain unchanged from embodiment 1.

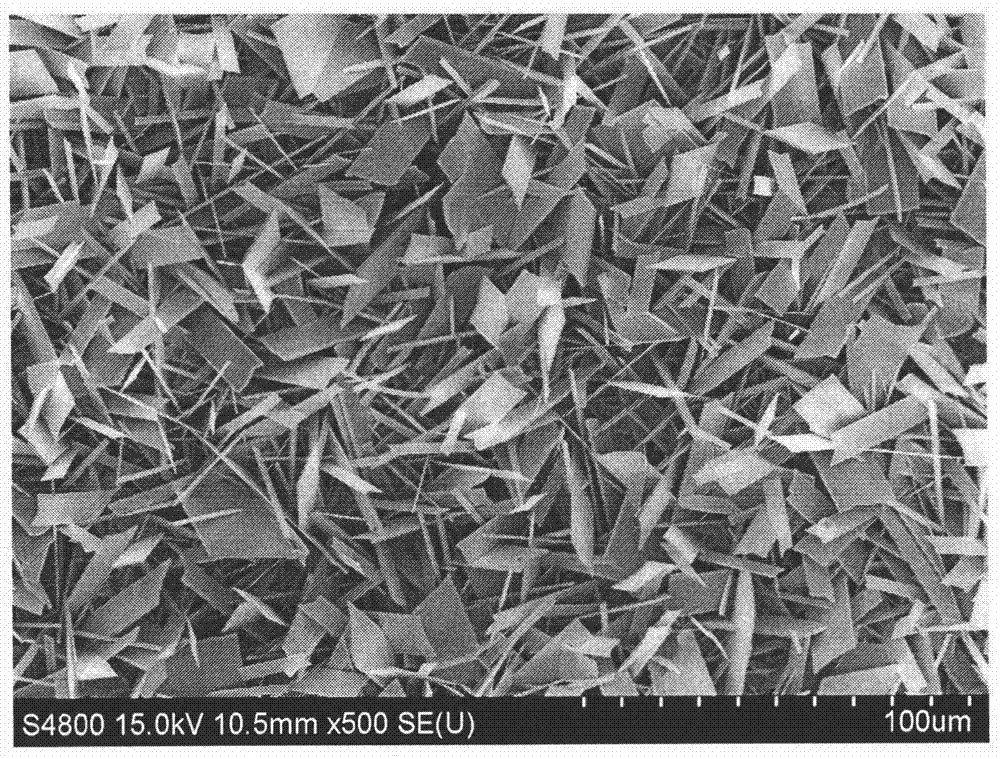

[0043] The sample prepared in Example 3 still maintains a uniform orthorhombic cubic crystal system without the existence of monoclinic and hexagonal crystal systems, but the thickness of the nanosheets increases significantly, so the deposition and growth time can effectively control the two-dimensional nanosheets thickness of.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com