An improved method for extracting alkali metal compounds from fluorine-fixed reconstituted lepidolite

A technology of alkali metal compounds and lepidolite, which is applied in the fields of alkali metal compounds, chemical instruments and methods, rubidium/cesium/francium compounds, etc., can solve the problems of large amount of acid scavenger, large material flow, waste of resources, etc., to achieve Eliminate uneven mixing, reduce production costs, and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

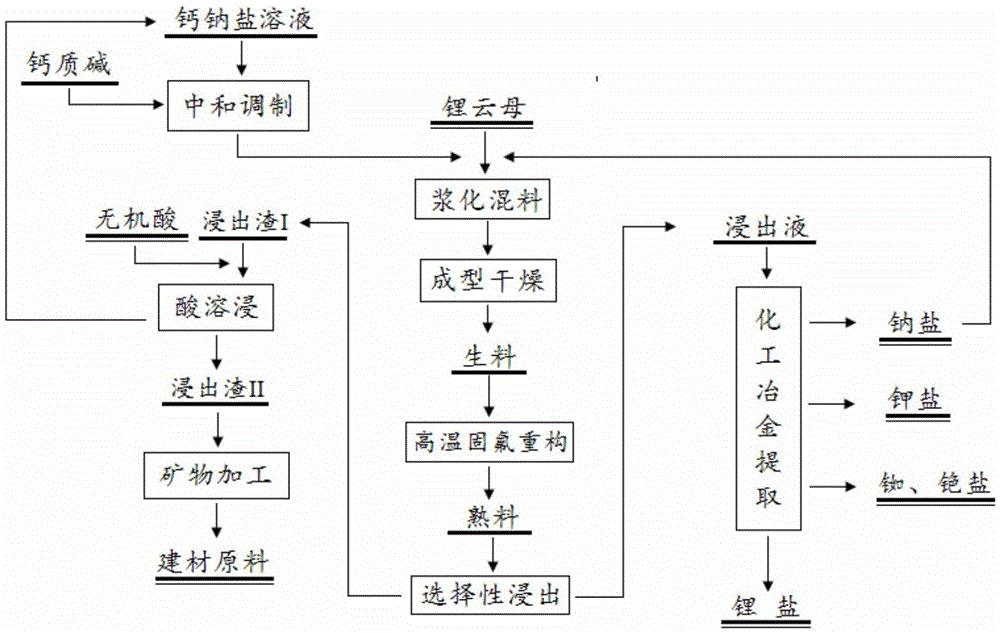

Image

Examples

Embodiment 1

[0054] Mix lepidolite powder and calcium sodium chloride solution according to the ratio of lepidolite: calcium sodium chloride: water = 1000:820:2000, stir and slurry for 20 minutes; dry and granulate the uniformly mixed slurry to make particle size 25 ~ 30mm, and then dried to less than 5% of raw material moisture. The granular raw meal is heat-treated in a heating furnace at 720°C for 20 minutes to produce clinker; the high-temperature flue gas is cooled and absorbed by water to make acid. The clinker is soaked in water according to the initial liquid-solid mass ratio of 2:1, filtered and separated, and the slag is washed; after the solution is purified and concentrated, it is transferred to lithium carbonate for precipitation; after the lithium precipitation mother liquor is treated, it is transferred to rubidium and cesium salt for extraction.

[0055] The main mineral phase composition of the leaching slag dry basis is: CaF 2 7%; CaO.Al 2 o 3 .2SiO2 2 63%; CaO.SiO 2...

Embodiment 2

[0059] Mix lepidolite powder and calcium sodium chloride solution according to the ratio of lepidolite: calcium sodium chloride: water = 1000:710:1500, stir and slurry for 30 minutes; dry and granulate the uniformly mixed slurry to make particle size 5 ~ 10mm, and then dried to less than 5% of the raw material moisture. The granular raw meal is heat-treated in a heating furnace at 880°C for 40 minutes to produce clinker; the high-temperature flue gas is cooled and absorbed by water to make acid. The clinker is soaked in water according to the initial liquid-solid mass ratio of 2:1, filtered and separated, and the slag is washed; after the solution is purified and concentrated, it is transferred to lithium carbonate for precipitation; after the lithium precipitation mother liquor is treated, it is transferred to rubidium and cesium salt for extraction.

[0060] The main mineral phase composition of the leaching slag dry basis is: CaF 2 6.7%; CaO.Al 2 o 3 .2SiO2 2 61%; CaO.S...

Embodiment 3

[0064] Mix lepidolite powder and calcium sodium chloride solution according to the ratio of lepidolite: calcium sodium chloride: water = 1000:760:1800, stir and slurry for 25 minutes; dry and granulate the uniformly mixed slurry to make particle size 15 ~ 20mm, and then dried to less than 5% of the raw material moisture. The granular raw meal is heat-treated in a heating furnace at 800°C for 30 minutes to produce clinker; the high-temperature flue gas is cooled and absorbed by water to make acid. The clinker is soaked in water according to the initial liquid-solid mass ratio of 2:1, filtered and separated, and the slag is washed; after the solution is purified and concentrated, it is transferred to lithium carbonate for precipitation; after the lithium precipitation mother liquor is treated, it is transferred to rubidium and cesium salt for extraction.

[0065] The main mineral phase composition of the leaching slag dry basis is: CaF 2 6.9%; CaO.Al 2 o 3 .2SiO2 2 61.7%; Ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com