Preparation method of light-induced phase transition storage powdery material lamda-Ti3O5

A powder material, photoinduced phase change technology, applied in the direction of titanium oxide/hydroxide, etc., can solve the problems of high cost, unsafe, complicated operation, etc., and achieve the effect of low cost, high production efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

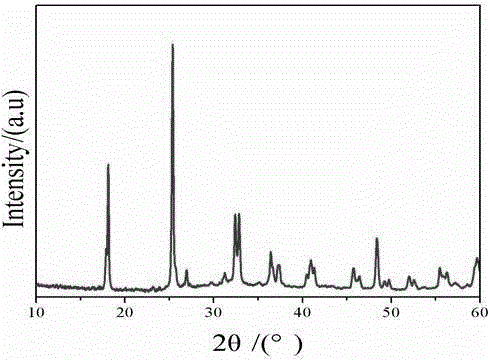

[0024] 1. According to Ti 3 o 5 The chemical reaction between the powder and the raw materials used is to measure each raw material, and the weight percentage of each raw material is as follows:

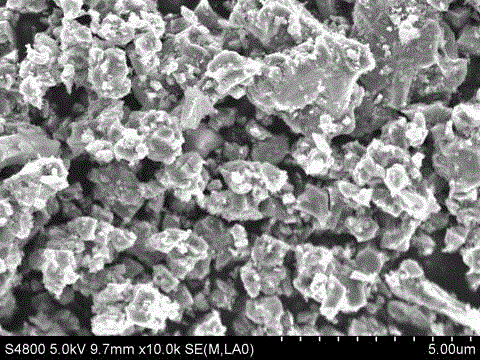

[0025] Pure rutile nano-TiO 2 Powder (30-50nm particle size) is 95.5wt%, carbon black powder is 4.5wt%; nano-TiO in the above raw materials 2 The powder has been surface-treated with 3.0wt% zirconate coupling agent;

[0026] 2. Put the raw materials measured in step 1 into the container, use analytical pure alcohol as the mixing medium, and ultrasonically disperse the raw materials to mix them evenly. Drying at high temperature for 6 hours to obtain mixed powder; place the dried powder in a mortar and grind to make it further mixed evenly;

[0027] 3. Weigh the powder obtained in step 2 in stages, weigh 2.0g each time, put it in the mold, slowly apply pressure to 12Mpa, and let it stand for 5min when the predetermined pressure is reached, then demould and sample, and obtain ...

Embodiment 2

[0030] 1. According to Ti 3 o 5 The chemical reaction between the powder and the raw materials used is to measure each raw material, and the weight percentage of each raw material is as follows:

[0031] Nano-TiO 2 Powder (particle size 20-30nm, TiO 2 The phase composition is 90wt% rutile type and 10wt% anatase type) is 95wt%, graphite powder is 5wt%;

[0032] Nano-TiO in the above raw materials 2 The powder has been surface-treated with 5.0wt% aluminate coupling agent;

[0033] 2. Put the raw materials measured in step 1 into a container, use industrial alcohol as the mixing medium, stir and disperse the raw materials to mix evenly, pour out the supernatant after centrifugation, and place the mixed slurry obtained by centrifugation in an oven at 100°C Dry for 3 hours to obtain mixed powder; grind the dried powder to make it further mixed evenly;

[0034] 3. Weigh the powder obtained in step 2 in stages, weigh 1.0g each time, put it in the mold, slowly apply pressure to ...

Embodiment 3

[0037] 1. According to Ti 3 o 5 The chemical reaction between the powder and the raw materials used is to measure each raw material, and the weight percentage of each raw material is as follows:

[0038] Pure anatase nano-TiO 2 Powder (particle size 10-20nm) is 94.0wt%, activated carbon powder is 6.0wt%;

[0039] Nano-TiO in the above raw materials 2 The powder has been surface treated with 3.0wt% aluminate coupling agent and 2.0wt% zirconate coupling agent;

[0040] 2. Put the raw materials measured in step 1 into a container, use acetone as the mixing medium, and ultrasonically disperse the raw materials to mix them evenly. After centrifuging, pour out the supernatant, and put the mixed slurry obtained by centrifugation in an oven to dry at 50°C. The mixed powder was obtained in 12 hours; the dried powder was ground to further mix it evenly;

[0041] 3. Weigh the powder obtained in step 2 in stages, weigh 2.5g each time, place it in the mold, slowly apply pressure to 8M...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com