Turmeric saponin compound enzyme reagent, preparation method thereof and method of utilizing same to prepare turmeric saponin

A technology of turmeric saponin and compound enzymes, applied in the direction of biochemical equipment and methods, enzymes, enzymes, etc., to achieve the effect of reducing gasoline consumption, reducing fermentation time, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

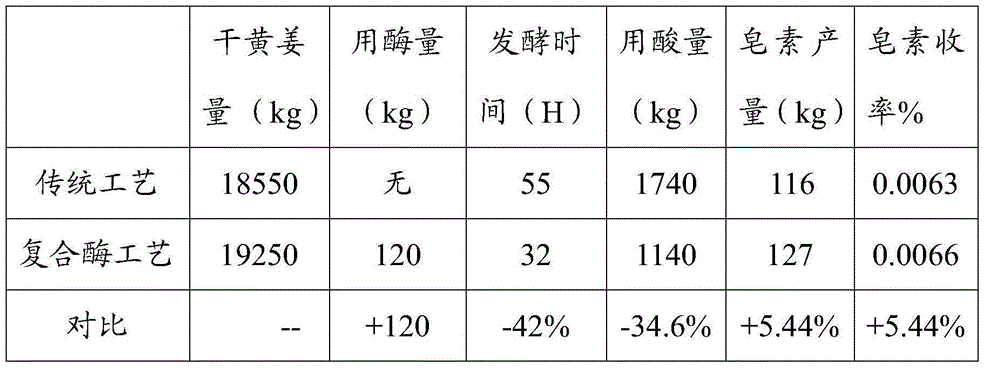

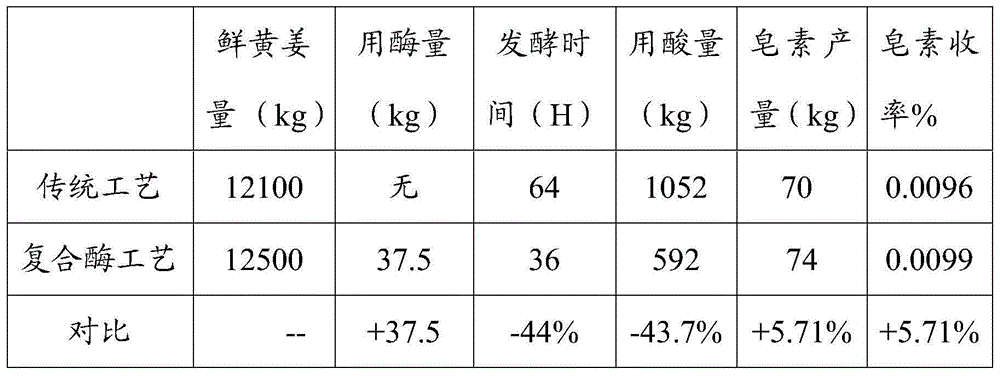

Examples

Embodiment Construction

[0024] Aiming at the problems existing in the prior art, the present invention finds on the basis of multiple experimental analysis: the rhizome of turmeric (Dioscorea shield leaf) contains 1.1%~16.15% of diosgenin, about 45% of starch, 40% of Cellulose, 2% to 3% pectin, and some water-soluble glycosides, alkaloids, flavonoid glycosides, cardiac glycosides, alkaloids, tannins, pigments and other chemical components, of which pectin is based on D2 half The A21,4 polymer of lacturonic acid is a polysaccharide whose main component is. Pectin uses partially methylated polygalacturonic acid as the main chain, and rhamnose, arabinose, galactose, xylose and other sugars are connected to the main chain as branch chains to form polysaccharides. Pectin-like structure. This polysaccharide structure bonds the protein, fatty alcohol, fatty acid and its esters, cholesterol and other hydrocarbons in the primary cell wall of the cellulose matrix through its main chain and branched chain. , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com