A kind of transparent polyester imide resin and preparation method thereof

A technology of polyester imide resin and polyester imide, which is applied in the field of transparent polyester imide resin and its preparation, can solve the problems of reduced transparency and lower glass transition temperature of polyimide, and achieves Effects of lower water absorption, lower electron affinity, and higher glass transition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

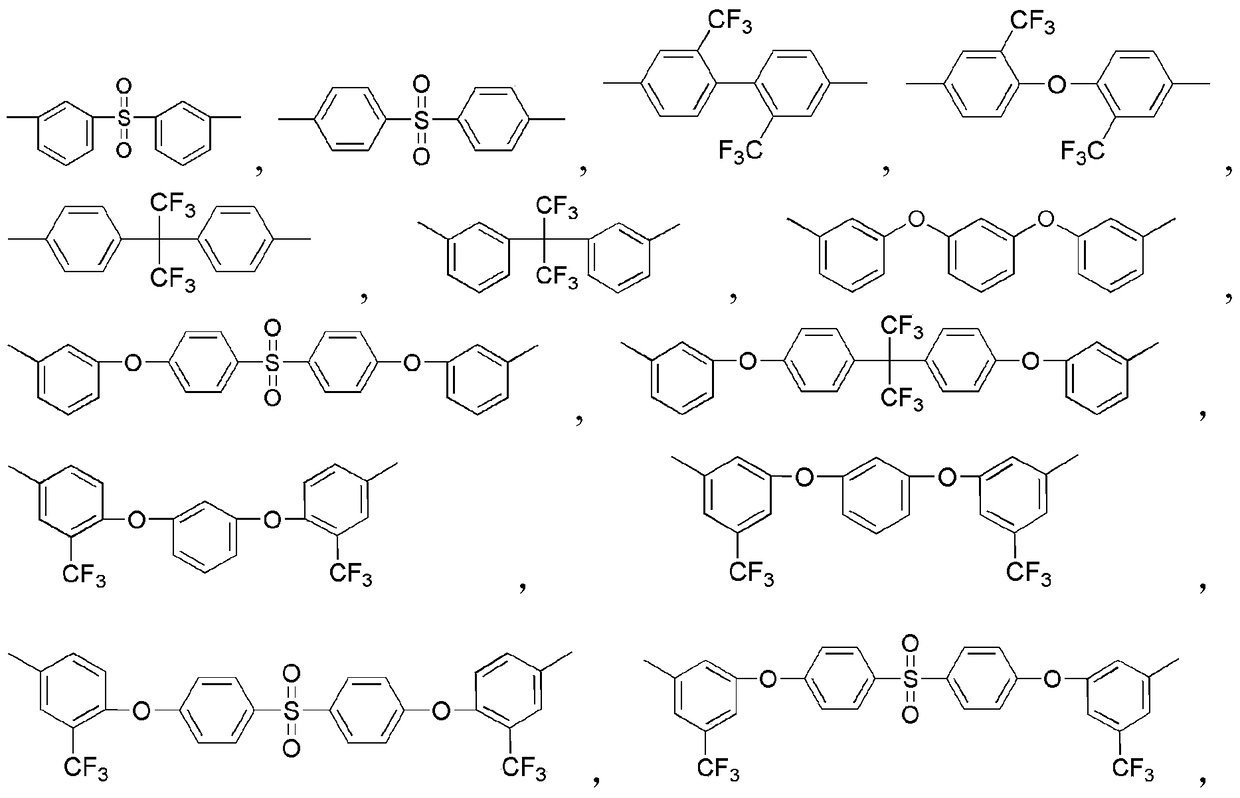

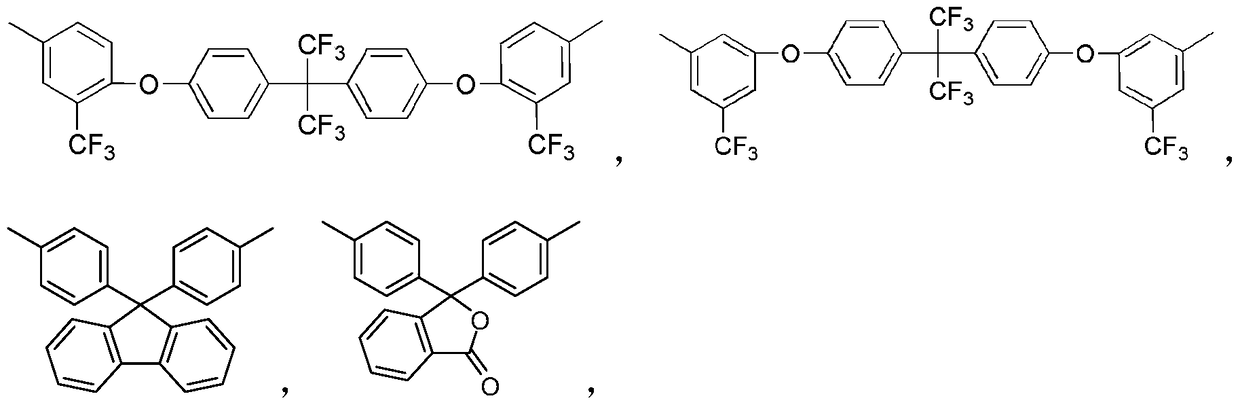

Method used

Image

Examples

Embodiment 1

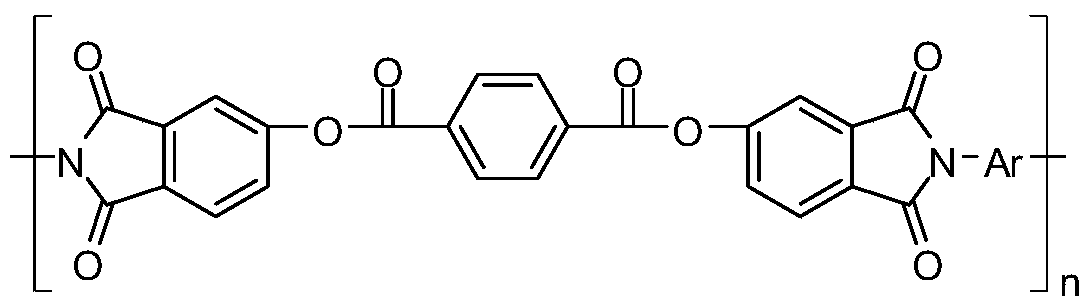

[0036] In this embodiment, the transparent polyester-imide resin material has the following structural formula:

[0037]

[0038] The specific preparation method is: under the protection of nitrogen, add 1.7230g (4.0mmol) of 4,4'-bis(3-aminophenoxy)diphenylsulfone and 16ml of N,N-dimethylacetamide to 50ml of reaction In the bottle, stir at room temperature. After the 4,4'-bis(3-aminophenoxy)diphenyl sulfone is completely dissolved, add 1.8334g (4.0mmol) of bis(3,4-dimethyl Anhydride) phenyl ester, continue stirring at room temperature for 24 hours to obtain a viscous polyester amic acid solution, and then dilute the solution to a concentration of 10% by weight. Then, a mixed solution of 4 mL of acetic anhydride and 2 mL of pyridine was added, and stirring was continued at room temperature for 24 hours to obtain a polyesterimide solution. The reaction solution is dropped into ethanol to obtain fibrous polyester imide precipitates, and dried to obtain polyester imide powder....

Embodiment 2

[0048] In this embodiment, the transparent polyester-imide resin material has the following structural formula:

[0049]

[0050] The specific preparation method is: under the protection of nitrogen, mix 1.3450g (4.0mmol) of 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl ether and 16ml of N,N-dimethyl Add acetamide into a 50mL reaction bottle, stir at room temperature, and after 2,2'-bis(trifluoromethyl)-4,4'-diaminodiphenyl ether is completely dissolved, add 1.8333g (4.0mmol) of p-phenylene Dicarboxylic acid bis(3,4-dicarboxylic anhydride)phenyl ester was stirred at room temperature for 24 hours to obtain a viscous polyester amic acid solution, and then the solution was diluted to a concentration of 10% by weight.

[0051] Apply the diluted polyester amic acid solution evenly on a clean glass plate, the thickness of the solution coating film is 0.5mm, place the glass plate in a drying oven, and heat up according to the following procedure: 80°C, 1 hour ; 150°C, 1 hour; 26...

Embodiment 3

[0054] In this embodiment, the transparent polyester-imide resin material has the following structural formula:

[0055]

[0056] The specific preparation method is: under nitrogen protection, mix 2.2740 (4.0 mmol) of 4,4'-bis(2-trifluoromethyl-4-aminophenoxy)diphenyl sulfone and 16 ml of N,N-dimethyl Add acetamide into a 50mL reaction flask, stir at room temperature, and then add 1.8333g (4.0mmol) of p- Bis(3,4-dicarboxylic anhydride)phenyl phthalate was stirred at room temperature for 24 hours to obtain a viscous polyester amic acid solution, and then the solution was diluted to a concentration of 10% by weight. Then, a mixed solution of 4 mL of acetic anhydride and 2 mL of pyridine was added, and stirring was continued at room temperature for 24 hours to obtain a polyesterimide solution. The reaction solution is dropped into ethanol to obtain fibrous polyester imide precipitates, and dried to obtain polyester imide powder. The glass transition temperature of the polyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com