Curable resin composition, dry film and printed circuit board

A technology of curable resin and composition, applied in printed circuit parts, optics, optomechanical equipment, etc., can solve problems such as inability to obtain sufficient signal characteristics, and achieve the effect of suppressing delay

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

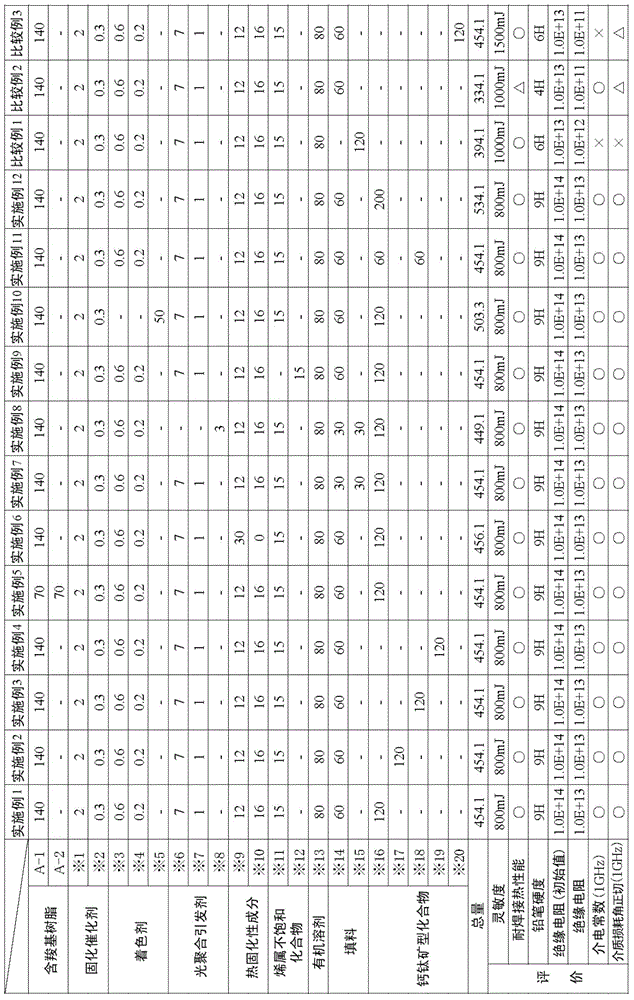

[0110] Examples and comparative examples are shown below to specifically describe the present invention, but the present invention is not limited to the following examples. It should be noted that, below, "parts" and "%" are all quality standards unless otherwise specified.

[0111]

Synthetic example 1

[0113] Put 119.4 parts of novolac cresol resin (manufactured by Showa Highpolymer Co., Ltd., trade name "ShonolCRG951", OH equivalent: 119.4), hydrogen in an autoclave equipped with a thermometer, nitrogen introduction device, alkylene oxide introduction device, and stirring device 1.19 parts of potassium oxide and 119.4 parts of toluene were stirred and replaced with nitrogen in the system, and then heated and increased. Then, slowly add 63.8 parts of propylene oxide dropwise at 125~132℃, 0~4.8kg / cm 2 Let it react for 16 hours. Then, it was cooled to room temperature, and 1.56 parts of 89% phosphoric acid was added to the reaction solution and mixed to neutralize potassium hydroxide to obtain a novolac type cresol resin epoxy with a non-volatile content of 62.1% and a hydroxyl value of 182.2 g / eq. Propane reaction solution. This is an average addition of 1.08 moles of alkylene oxide per equivalent of phenolic hydroxyl group.

[0114] Next, 293.0 parts of the obtained novolac t...

Synthetic example 2

[0116] Put methyl methacrylate, ethyl methacrylate, and methacrylic acid into a flask equipped with a thermometer, a stirrer, a dropping funnel, and a reflux condenser in a molar ratio of 1:1:2, and add two as a solvent. Propylene glycol monomethyl ether, azobisisobutyronitrile (AIBN) was added as a catalyst, and stirred at 80°C for 4 hours under a nitrogen atmosphere to obtain a resin solution. The resin solution was cooled, methylhydroquinone was used as a polymerization inhibitor, and tetrabutylphosphorus bromide was used as a catalyst. The addition of 20 mol% to the carboxyl group of the resin was carried out at 95-105°C for 16 hours. The addition reaction of glycidyl acrylate is taken out after cooling. The solid substance of the thus obtained carboxyl group-containing photosensitive resin having both ethylenic unsaturated bonds and carboxyl groups has an acid value of 120 mgKOH / g, a non-volatile content of 71%, and a Mw of about 20,000. This resin solution is referred to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com