Inorganic/organic semiconductor nano-composite structure and preparation method and application thereof

A technology of organic semiconductors and inorganic semiconductors, applied in the field of semiconductor photocatalysis, can solve the problems of narrow absorption band and limited solar energy utilization rate, and achieve the effect of improving utilization rate and efficient photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Preparation of TiO 2 nanotube array film

[0037] 1) Take a titanium foil sample with a length of 2.0cm, a width of 2.0cm, a thickness of 0.25mm, and a purity >99.9%, and pass through HF / HNO 3 / H 2 After etching with O (volume ratio, 1:4:2) solution for 10s, ultrasonic cleaning was performed in acetone, absolute ethanol and water in the same order for 30min to complete the pretreatment of the titanium substrate;

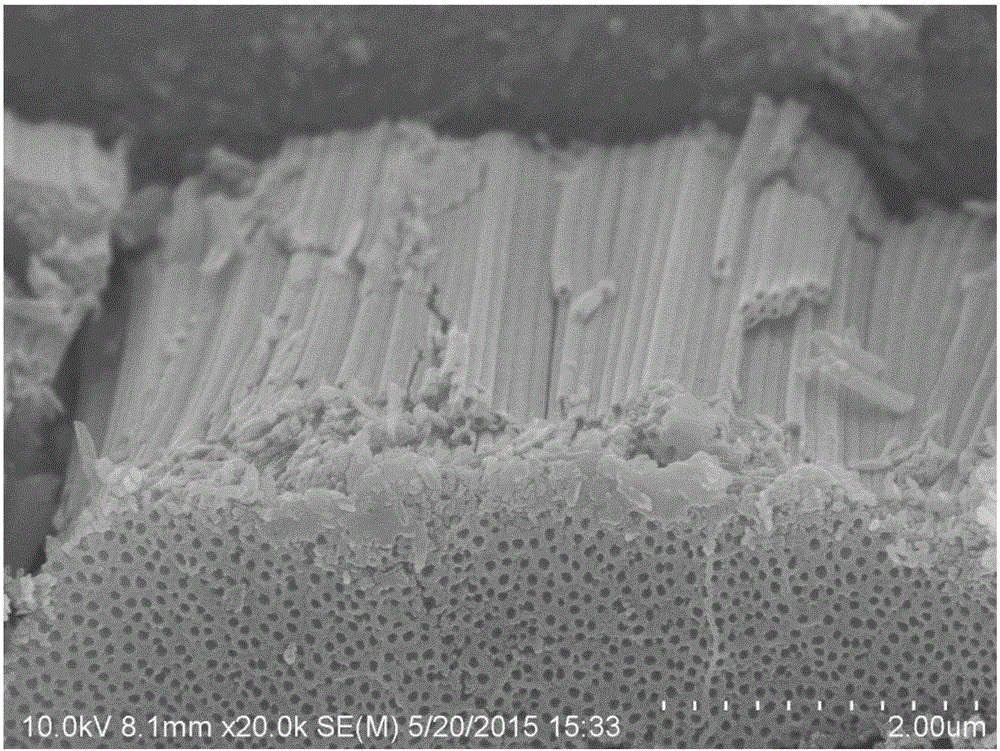

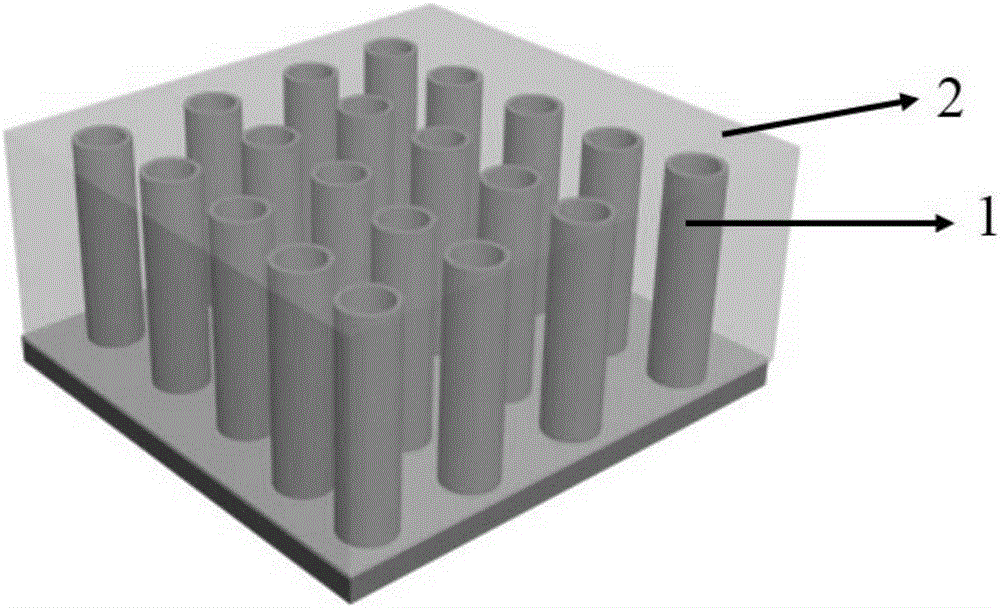

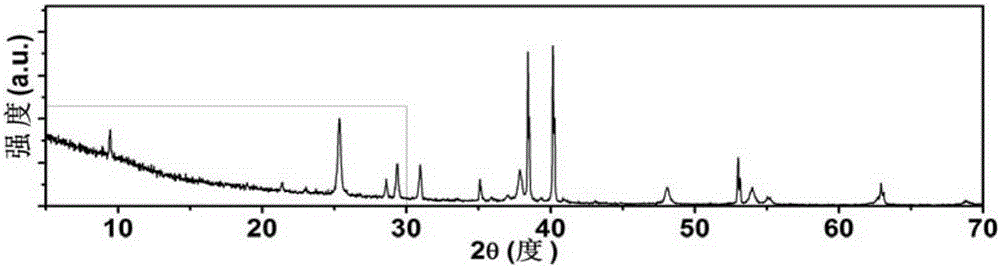

[0038] 2) The treated titanium substrate is used as the anode, and the platinum mesh is used as the cathode, containing 0.2wt% NH 4 F's ethylene glycol: water (volume ratio 50:1) solution is used as the electrolyte, and a voltage of 60V is applied to anodize the titanium substrate for 60min. After the reaction, the samples were washed with deionized water, dried and calcined in a box-type sintering furnace at 450 °C for 3 h. figure 1 It can be seen that the pore diameter of the nanotube is about 50 nm, the wall thickness is about 25 nm, and the length of t...

Embodiment 2

[0040] deposited on TiO2 The structure of dicyclohexane-perylene tetraimide (N,N-(dicyclohexyl)perylene-3,4,9,10-tetracarboxylicdiimide, CH-PTCDI) on the inner and outer surfaces of nanotubes is shown in Formula 1:

[0041]

[0042] (1)

Embodiment 3

[0044] Repeat Example 2, deposited on TiO 2 The diphenyl-perylene tetraacid diimide structure on the inner and outer surfaces of the nanotubes is shown in Formula 2:

[0045]

[0046] (2)

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Tube chief | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com