Six-stroke incremental combustion gasoline and diesel engine

An additive, six-stroke technology, used in machines/engines, mechanical equipment, etc., to solve problems such as unqualified emissions, high compression ratios, and in-cylinder misfires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

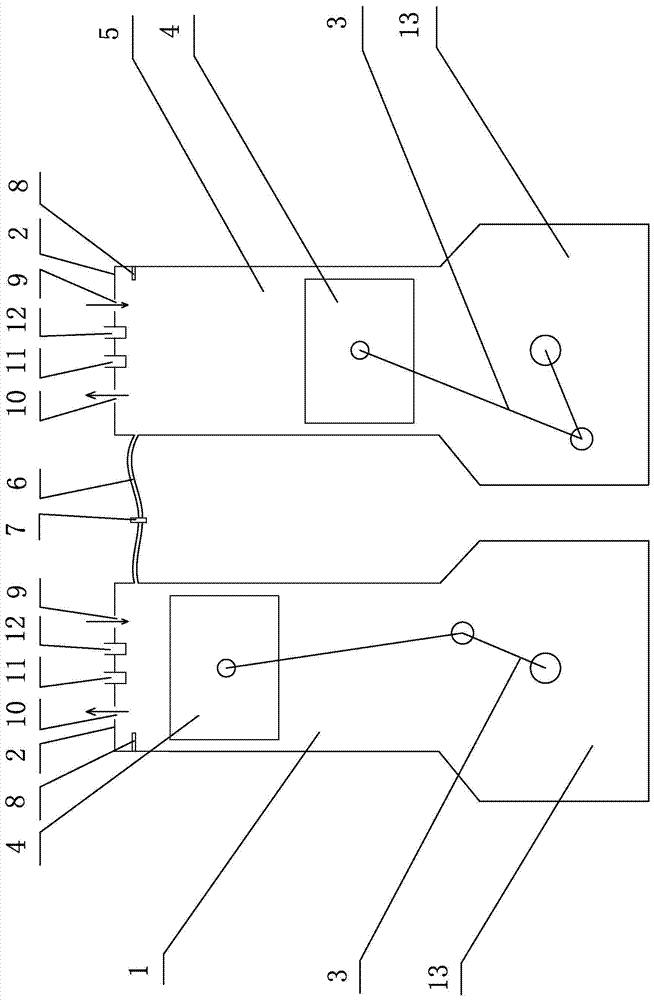

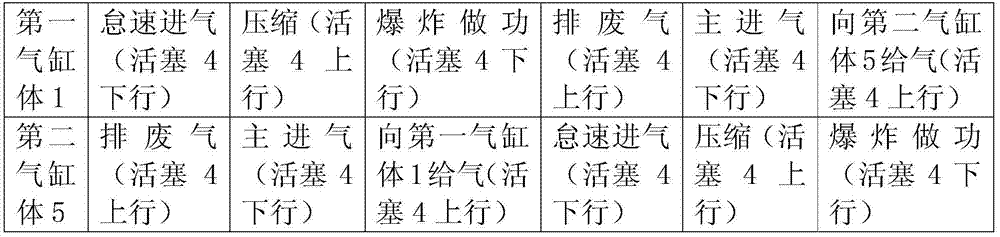

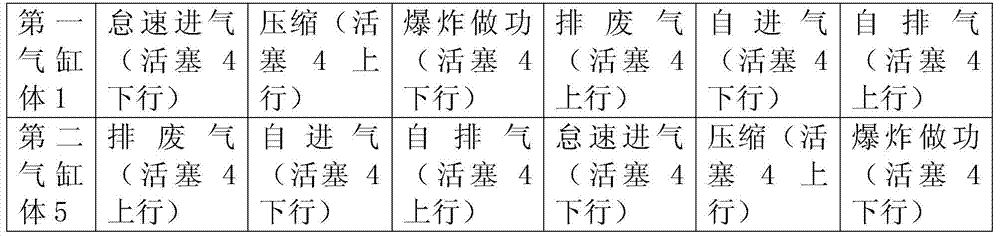

[0039] figure 1 Shown is an embodiment of a six-stroke progressively added combustion gasoline and diesel engine of the present invention, which is represented as a gasoline engine, and the engine has cylinder blocks that are an even multiple of 2, and two cylinder blocks are used in pairs. figure 1 The two shown cylinder blocks used in pairs are respectively defined as a first cylinder block 1 and a second cylinder block 5 .

[0040] In a single cylinder block, the upper port of the cylinder block is closed by the cylinder head 2, and the cylinder head 2 is provided with an air inlet 9 and an exhaust port 10, and is provided with a fuel injector 11 and a spark plug 12, and the lower port of the cylinder block is connected to the crank Case 13, described crankcase 13 is provided with crankshaft linkage mechanism 3 (crankshaft drives connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com