Microbial fuel cell and method for treating wastewater by using same

A fuel cell and microbial technology, applied in the field of sustainable biological treatment of wastewater, can solve problems such as limited oxygen solubility, weakened microbial metabolic activity, harshness, etc., achieve stable and efficient nitrogen and carbon removal, improve oxygen mass transfer efficiency, and stable performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

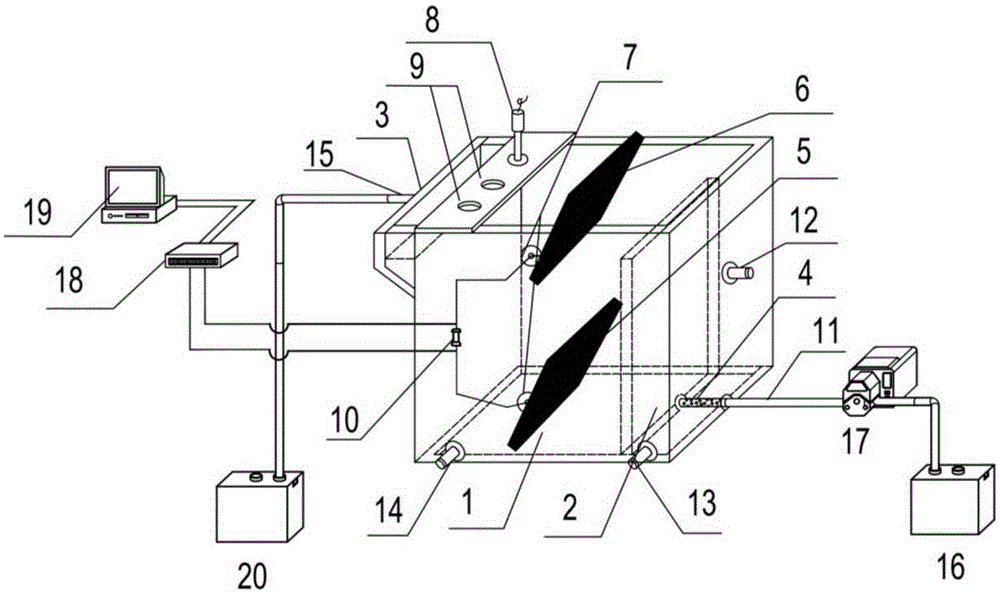

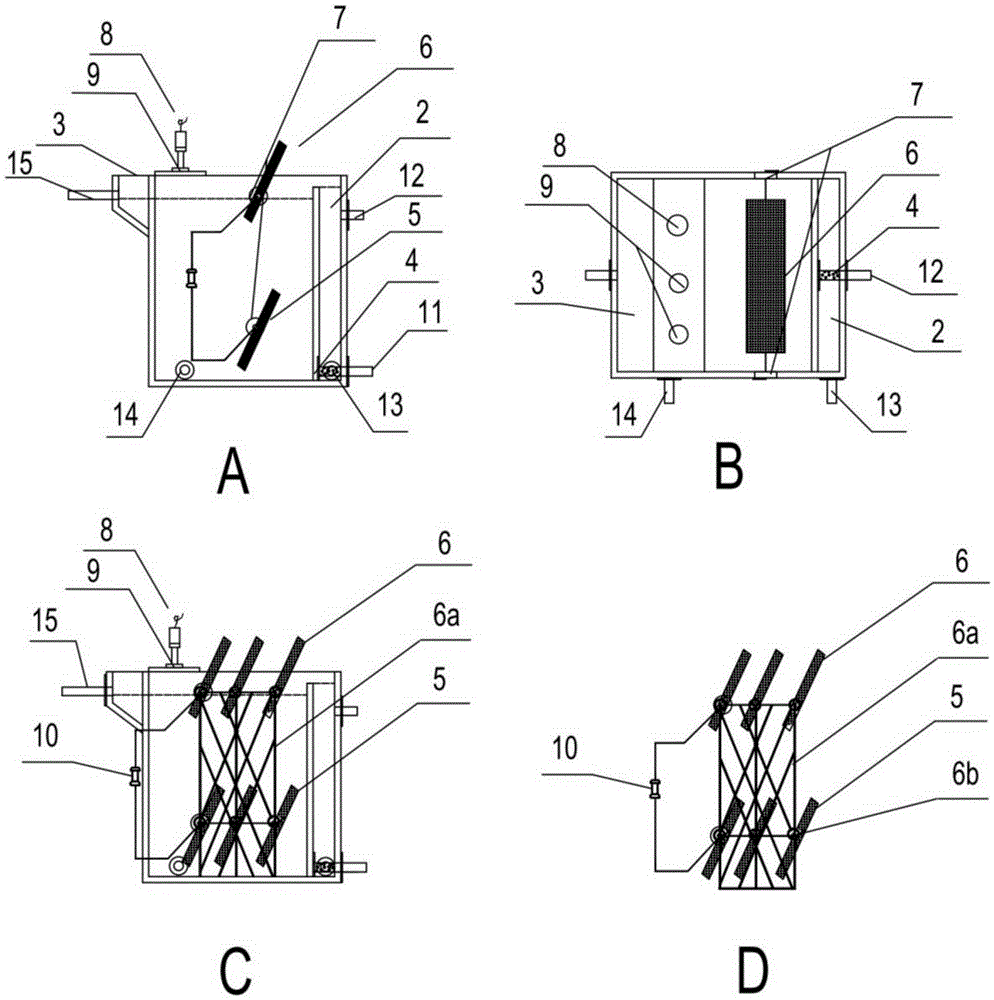

[0033] Such as figure 1 As shown, an air cathode microbial fuel cell based on capillary action includes a main reaction area 1, a biological selection adjustment area 2, an overflow outlet tank 3, a perforated water pipe 4, a biological anode 5, an air cathode 6, an electrode bracket 6a, and an electrode card slot 6b. Cathode and anode electrode socket sealing ring 7, reference electrode 8, PH and DO electrode socket 9-I and II, external resistor 10, water inlet pipe 11, monitoring port 12, emptying pipe 13 and 14, water outlet pipe 15 Composition; the main reaction zone 1 is an open columnar or cubic structure, and the electrode jacks 9-I and II are arranged on the main reaction zone 1; Part of the cathode is exposed to the air, and the area of the cathode exposed to the air accounts for 1 / 4 of the entire cathode; other auxiliary equipment includes a water inlet pool 16, a peristaltic pump 17, a data acquisition card 18, a data processing and display system 19, As well as ...

Embodiment 2

[0041] The structure and operating conditions of the experimental device in this example are consistent with those in Example 1, the area of the cathode exposed to air is adjusted to account for 50% of the entire cathode area, and relevant data are recorded. The result is as follows:

[0042]

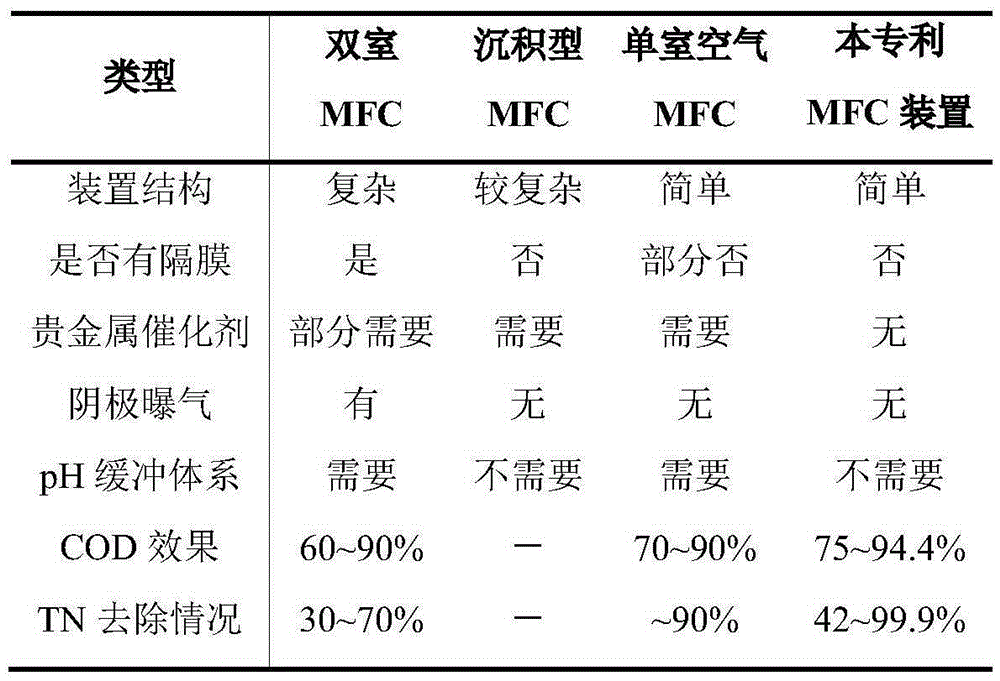

[0043] As can be seen from the table, when the exposed air area of the cathode accounts for 50% of the entire cathode area, the COD removal rate reaches 85-93%, and the ammonia nitrogen removal rate reaches 50-85%, which are slightly improved compared with Example 1.

Embodiment 3

[0045] In this example, the experimental device and operating conditions used were consistent with those in Example 1, and the area of the cathode exposed to air was further adjusted to account for 90% of the entire cathode area, and relevant data were recorded. The result is as follows:

[0046]

[0047] It can be seen from the table that when the area of the cathode exposed to air accounts for 90% of the entire cathode area, the removal rate of COD reaches 87.5-94.4%, and the removal rate of ammonia nitrogen reaches 98.7-99.9%. COD and ammonia nitrogen removal efficiency are significantly improved compared with embodiment 1 and embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric current | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com