Room-temperature rust removal blackening agent and preparation method thereof

A blackening agent and normal temperature technology, applied in coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problem of poor bonding between the blackened layer and the base metal, insufficient stability of resin and carbon black dispersion, and high price of selenide, etc. problem, to achieve the effect of fast rust removal and blackening speed, uniform rust removal and blackening speed, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

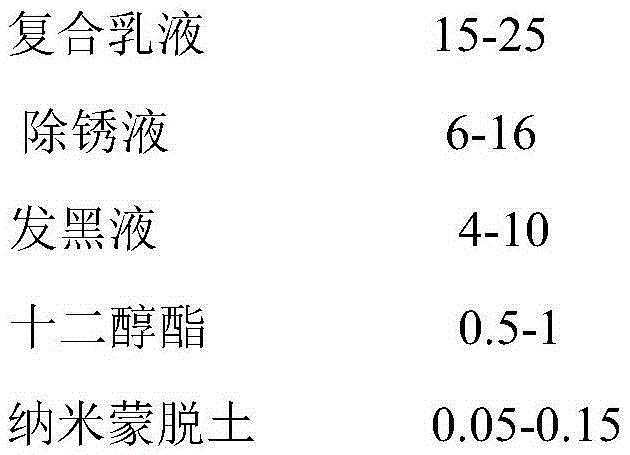

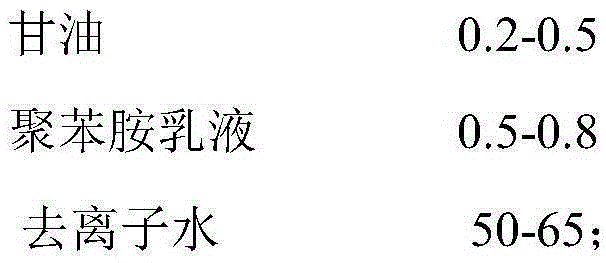

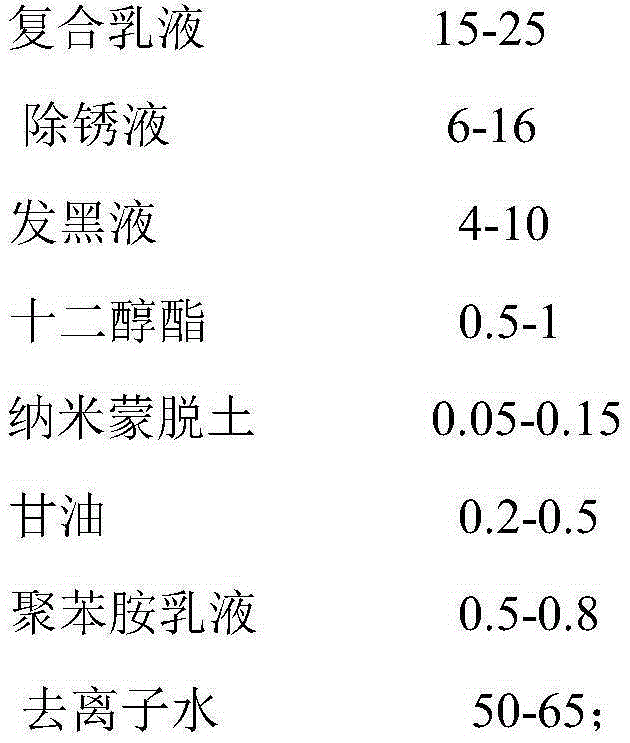

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1: the preparation method concrete steps of a kind of normal temperature derusting and blackening agent of the present invention are as follows:

[0021] (1) Preparation of derusting solution:

[0022] Add 5 grams of oxalic acid to 70 grams of deionized water and stir to dissolve it completely, then slowly add 20 grams of 85% phosphoric acid and stir evenly, and finally add 5 grams of zinc phosphate and continue to stir for 0.5 hours at room temperature. Get rust remover.

[0023] (2) Preparation of blackening liquid:

[0024] Add 10 grams of pyrogallol to 78 grams of deionized water and stir to make it completely dissolved, then add 10 grams of salicylic acid and stir evenly, finally add 2 grams of sodium gluconate, and continue to stir at room temperature for 0.5 hours to prepare Gotta turn black.

[0025] (3) Preparation of composite emulsion:

[0026] Add 10 grams of epoxy emulsion to 60 grams of modified acrylate antirust emulsion and stir evenly, th...

Embodiment 2

[0029] Embodiment 2: the preparation method concrete steps of a kind of normal temperature derusting and blackening agent of the present invention are as follows:

[0030] Steps (1), (2) and (3) are the same as in Example 1.

[0031] (4) Preparation of target product normal temperature derusting and blackening agent:

[0032] Add 0.05 grams of nano-montmorillonite, 0.2 grams of glycerin and 0.6 grams of polyaniline emulsion to 50 grams of deionized water and stir evenly. First, add 16 grams of the rust removal solution prepared in step (1) while stirring continuously. After stirring Then slowly add 4 grams of the blackening liquid prepared in step (2), continue to stir and disperse for 20 minutes, then slowly add 15 grams of step (3) composite emulsion, and finally slowly add 0.5 gram of lauryl alcohol ester, and continue stirring for 0.5 hours at normal temperature to prepare Obtain described normal temperature derusting and blackening agent.

Embodiment 3

[0033] Embodiment 3: the preparation method concrete steps of a kind of normal temperature derusting and blackening agent of the present invention are as follows:

[0034] Steps (1), (2) and (3) are the same as in Example 1.

[0035] (4) Preparation of target product normal temperature derusting and blackening agent:

[0036] Add 0.15 gram of nano-montmorillonite, 0.3 gram of glycerol and 0.8 gram of polyaniline emulsion to 65 grams of deionized water and stir evenly. In the case of constant stirring, first add 6 grams of the rust removal solution prepared in step (1), and stir evenly. Then slowly add 10 grams of the blackening liquid prepared in step (2), continue to stir and disperse for 20 minutes, then slowly add 25 grams of step (3) composite emulsion, and finally slowly add 1 gram of lauryl alcohol ester, and continue stirring for 0.5 hours at normal temperature to prepare Obtain described normal temperature derusting and blackening agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com