3D printing preparation method of bond defect repair stent

A 3D printing and bone defect technology, which is applied in the preparation of biomedical tissue engineering scaffold materials, and the 3D printing preparation of new multi-level microstructure calcium-phosphorus-silicon-based active bone repair material scaffolds, can solve the toxic and side effects of pore-forming agents, lack of Problems such as pore structure space direction, connectivity control, lack of manufacturing complex shapes, etc., to achieve optimized mechanical properties, good biological activity and osteogenesis effect, and facilitate the effect of adherent proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] In the preparation method of the calcium-containing mesoporous silicon, the calcium source is added twice, and the calcium source is added for the first time to play the role of imprint, forming a reserved space in the material, and in step 1), the deionized water can be washed to remove the calcium source. The calcium source is cleaned, and after adding the calcium source in step 2), it is sintered to form a stable structure.

[0025] In the above preparation method of calcium-containing mesoporous silicon, the hydrothermal reaction temperature, time, sintering temperature, and heating rate play a key role in the performance of mesoporous silicon materials: as the temperature of the hydrothermal reaction increases, the average pore size of the sample increases , the specific surface area first increases and then decreases; as the hydrothermal reaction time increases, the average pore diameter of the sample increases first and then decreases, and the specific surface are...

Embodiment 1

[0029] A 3D printing preparation method of a bone defect repair bracket of the present invention comprises the following steps:

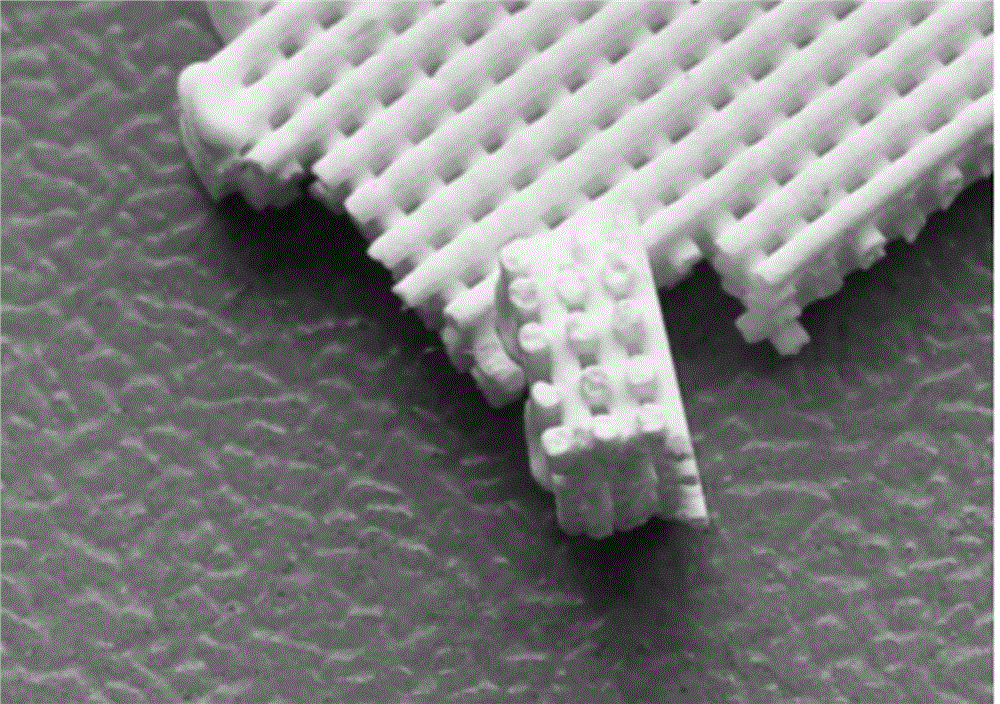

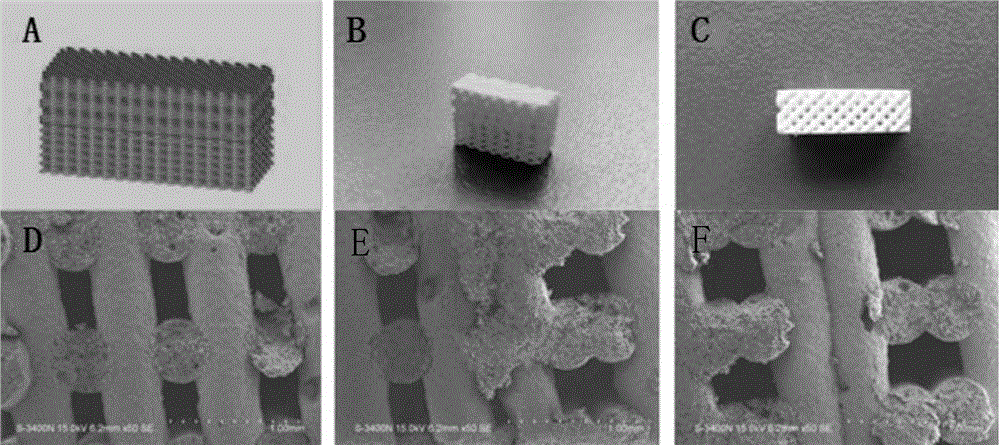

[0030] 1) Preparation of mesoporous silicon material: 4.0 g of polyoxyethylene-polyoxypropylene-polyoxyethylene triblock copolymer P123 was dissolved in 150 mL of hydrochloric acid solution with a concentration of 1.6 mol / L and stirred until the system was clear. 8.5g of TEOS was added dropwise to the solution. After TEOS was completely added and pre-hydrolyzed for 15 minutes, 2.6g of calcium nitrate tetrahydrate was gradually added to the solution. Stir at room temperature for 5 hours to disperse the system evenly. Set for aging for 24 hours, and then transfer to a hydrothermal reactor at 100°C for 48 hours of constant temperature reaction to obtain a precipitate. The precipitate was filtered, washed thoroughly with deionized water, and dried under vacuum at 60 °C to obtain a white powder. Disperse the dried powder in 150mL of deionized water, sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com