A nickel-based catalyst for methane-carbon dioxide reforming to reduce gas and its preparation method

A carbon dioxide and catalyst technology, applied in the field of nickel-based catalysts and their preparation, can solve the problems of lack of reforming catalyst parameters and reports, and achieve the effects of reducing production costs and operating risks, reducing reaction energy consumption, and good catalytic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

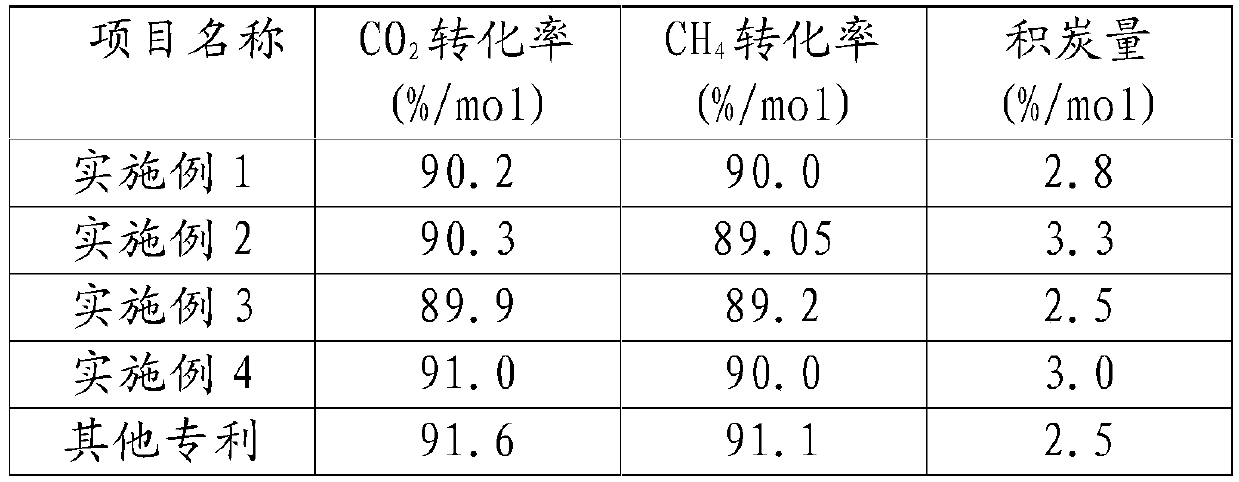

Examples

Embodiment 1

[0026] In this embodiment, a nickel-based catalyst used for methane-carbon dioxide reforming to produce reducing gas mainly includes active components, auxiliary agents and carriers, wherein:

[0027] The mixture of X-type molecular sieve and diatomaceous earth is used as raw material, and short fibers with a mass fraction of 3% are added as a pore-enlarging agent. After ball milling and forging, a honeycomb catalyst carrier can be obtained. The active components are nickel and rare earth metal lanthanum. As auxiliary agent: the mass fraction of nickel oxide in the catalyst is 10%, the mass fraction of lanthanum oxide is 3%, and the rest is carrier.

[0028] A kind of nickel-based catalyst used in the reforming of methane-carbon dioxide to produce reducing gas in this example is prepared through the following main steps:

[0029] (1) Carrier obtained by high-temperature calcination: X-type molecular sieve and diatomite (the mass ratio of X-type molecular sieve and diatomite is...

Embodiment 2

[0034] In this embodiment, a nickel-based catalyst used for methane-carbon dioxide reforming to produce reducing gas mainly includes active components, auxiliary agents and carriers, wherein:

[0035] The mixture of X-type molecular sieve and montmorillonite is used as raw material and pore-enlarging short fibers with a mass fraction of 5% are ball-milled and forged to obtain a honeycomb-type catalyst carrier. The active component is nickel, and the rare earth metal lanthanum is used as an auxiliary agent: The mass fraction of nickel oxide is 15%, the mass fraction of additives is 5%, and the rest is carrier. A kind of nickel-based catalyst used in the reforming of methane-carbon dioxide to produce reducing gas in this example is prepared through the following main steps:

[0036] (1) Carrier obtained by high-temperature calcination: X-type molecular sieve and montmorillonite (the mass ratio of X-type molecular sieve and montmorillonite is 1:1.5) and pore-enlarging short fiber...

Embodiment 3

[0043] In this embodiment, a nickel-based catalyst used for methane-carbon dioxide reforming to produce reducing gas mainly includes active components, auxiliary agents and carriers, wherein:

[0044] The mixture of Y-type molecular sieve and kaolin is used as the raw material, and the pore-enlarging agent lignin with a mass fraction of 3% can be forged by ball milling to obtain a honeycomb-type catalyst carrier. The active component is nickel, and the rare earth metal cerium is used as an auxiliary agent: Among them The mass fraction of nickel oxide is 20%, the mass fraction of auxiliary agent cerium oxide is 5%, and the rest is carrier. A kind of nickel-based catalyst used in the reforming of methane-carbon dioxide to produce reducing gas in this example is prepared through the following main steps:

[0045] (1) Carrier obtained by high-temperature calcination: the raw material Y-type molecular sieve and kaolin (the mass ratio of Y-type molecular sieve and kaolin is 1:1.5) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com