Method for extracting polypeptide through tadpole enzymolysis and polypeptide prepared by method

A tadpole and enzymatic hydrolysis technology, applied in the field of active peptides, can solve the problems of high industrial production costs and enzyme consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1, the preparation of immobilized nanozyme

[0039] (1) Weigh 10.812g of FeCl 3 ·H 2 O and 5.5724 g of FeSO 4 ·H 2 O(Fe 3+ and Fe 2+ The molar ratio is 2:1), added to 200mL of deionized water, stirred at 40°C, 500rpm under non-magnetic conditions for about 1h; then 2 Protect and continue to stir while adding ammonia water with a concentration of 8mol / L to keep the pH of the system at about 10. When the solution turns from yellow to black and the temperature rises to 82°C, continue to stir for about 1 hour at 400rpm under non-magnetic conditions; the reaction is over After cooling to room temperature, magnetic solid-liquid separation, the resulting precipitate is Fe3O 4The magnetic nanoparticles are washed with water until the pH is about 7, and temporarily stored in an aqueous acetic acid solution with a pH of 2-4 for later use, or vacuum freeze-dried for about 48 hours and stored at -20°C for a long time. Fe3O 4 The particle size of the magnetic nano...

Embodiment 2

[0044] Embodiment 2, the preparation of bullfrog tadpole enzymolysis polypeptide powder

[0045] (1) Collect 8-week-old live bullfrog tadpoles with a body weight of 24-25 g and a body length of about 15 cm after hatching, rinse them repeatedly with water to remove the attachments on the tadpole body surface; then place them in water for 2 days, and change the water 4 times during the period To remove the metabolites in the tadpoles; finally, treat them with 10% hydrogen peroxide for about 30 minutes to remove harmful substances on the surface of the tadpoles, wash them with water, and kill them by suffocation; vacuum freeze-dry and crush them into tadpole powder with a particle size of 80-100 μm.

[0046] Weigh 20kg of bullfrog tadpole powder, place it in the extraction kettle of a supercritical extraction device for degreasing treatment, the extraction pressure is 35MPa, the extraction temperature is 35°C, the extraction time is about 200min, and the degreased bullfrog tadpole...

Embodiment 3

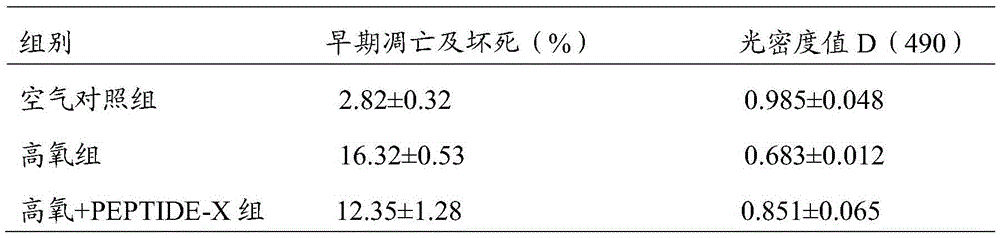

[0050] Embodiment 3, the separation of the polypeptide PEPTIDE-X with antioxidant activity

[0051] Get the refined enzymolysis solution 50ml that prepares in the embodiment 2, through ultrafiltration (filter membrane selects 5000Da) cut off the component that molecular weight is less than or equal to 5000Da; The temperature is room temperature, the detection wavelength is 280nm, collected according to time, 20 minutes / tube, and the antioxidant activity of each tube of liquid is measured. The higher the value, the better the oxidation resistance. Collect the tube with the highest absorbance value, that is, the tube with the best oxidation resistance.

[0052] The tube with the best oxidation resistance was separated and purified by RP-HPLC, using a C18 column, the mobile phase A was 0.1% TFA aqueous solution by volume, ultrasonically degassed before use, the mobile phase B was acetonitrile, and the detection wavelength was 215nm , the column temperature is room temperature, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com