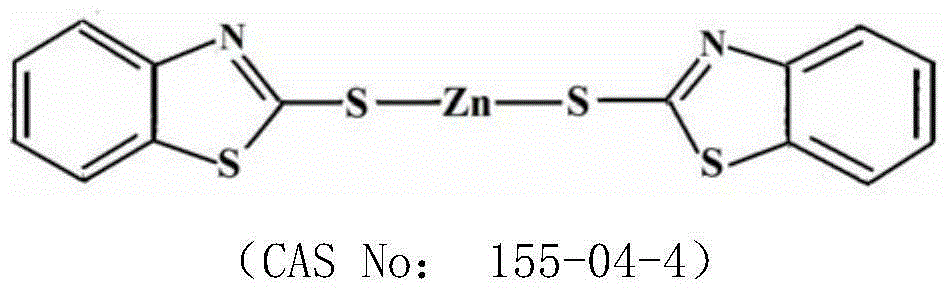

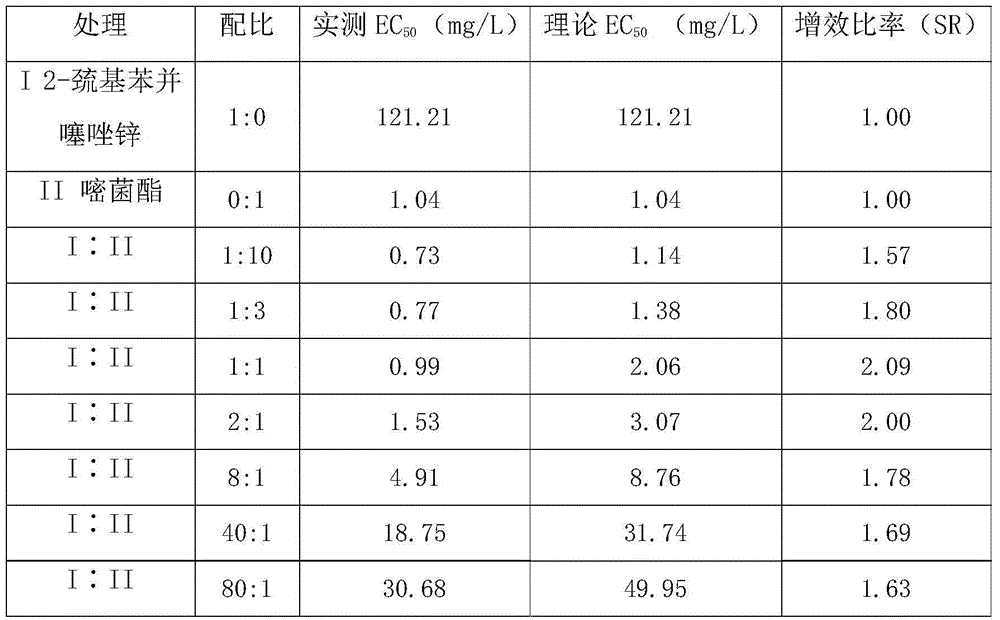

Zinc 2-mercaptobenzothiazole and mitochondrial cytochrome enzyme inhibitor bactericide composition

A composition, technology of thiazole zinc, applied in the field of agriculture, can solve the problems of easy resistance and inability to prevent and control multiple diseases at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0083] 40% active compound (35.0% 2-mercaptobenzothiazole zinc and 5.0% pyraclostrobin composition), fatty alcohol polyoxyethylene ether 2.0%, maleic acid-acrylic acid homopolymer sodium salt 3.0%, yellow Raw gum 0.05%, magnesium aluminum silicate 0.6%, sodium starch octenyl succinate 1.0%, glycerol 2.0%, phenyl salicylate 0.4%, silicone defoamer 0.1%, deionized water to 100 %, put it into a high-shear homogeneous emulsifier and shear it at high speed for 20 minutes, then transfer it to a sand mill, and circulate sand mill for 1-3 times to obtain a 40% content active compound suspending agent.

Embodiment 2

[0085] 30% active compound (20.0% 2-mercaptobenzothiazole zinc and 10.0% azoxystrobin combination), fatty alcohol polyoxyethylene ether sulfate 1.0%, phenolsulfonic acid condensate sodium salt 1.0%, polymer polycarboxylate Salt 2.0%, sodium starch octenyl succinate 2.0%, glycerol 2.0%, silicone defoamer 0.1%, Cathone 0.2%, deionized water to 100%, put into high-shear homogeneous emulsification High-speed shearing in the machine for 25 minutes, then pumped into a sand mill for 90 minutes of sand grinding, and filtered to obtain a 35% active compound suspension.

[0086] 2. Microcapsule suspension

Embodiment 3

[0088] 25% active compound (10.0% 2-mercaptobenzothiazole zinc and 15.0% trifloxystrobin composition) microcapsule suspension preparation method: 10.0% 2-mercaptobenzothiazole zinc, 15.0% trifloxystrobin, alkylnaphthalene Sulfonate 1.0%, acyl glutamate 2.0%, silicone defoamer 0.1%, polyphenyl polymethylene polyisocyanate PAPI 3% and diphenylmethane diisocyanate MDI 2%, gum arabic (5%) aqueous solution 10% and 40.46% deionized water are fully mixed, and then put into a sand mill for sand grinding until the D90 particle size is 3-5 microns. Start stirring (maintain 700 rpm), then raise the temperature of the sand-milled suspension to 60°C, and slowly add 0.04% triethanolamine at the same time to maintain a stable solidification temperature of the capsule wall material for 8 hours, then add fatty alcohol polyoxyethylene ether Sulfate 1.0%, sodium methylnaphthalenesulfonate formaldehyde condensate 1.0%, urea 2.0%, glycerol 2.0%, aluminum magnesium silicate (2%) aqueous solution 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com