Method for removing titanium and oxide skin on alloy surface of titanium

An oxide scale and alloy technology, applied in the direction of metal material coating process, can solve the problems of high production cost, large environmental protection pressure, high cost, etc., and achieve the effect of easy operation and implementation, improving product quality and reducing production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

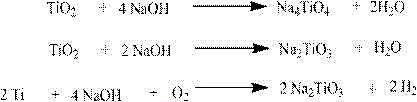

Method used

Image

Examples

Embodiment 1

[0036] Example 1. Dissolving 0.03 g of tetra-p-sulfonate phenylporphyrin iron (III) in 1 L of HCl solution with a concentration of 150 g / L, and 80 g of benzylamine were prepared as pickling solution, and 0.25 kg of titanium disks were cleaned at 80° C. strip.

[0037] Processing steps:

[0038] (1) Immerse the material to be cleaned in the pickling solution for 40 minutes;

[0039] (2) Put the cleaned material in water and ultrasonically treat it with an ultrasonic generator for 60s; (3) Immerse the cleaned material in a mixed solution of nitric acid and hydrofluoric acid for 10s; (4) Rinse the cleaned material with high-pressure water; (5) Soak the material to be cleaned in a borax solution with a pH of 10 and a temperature of 80°C for 2 minutes. After taking it out, rinse it with high-pressure water and dry it.

[0040] Treatment result: The scale of the titanium wire rod is completely removed, and its surface is a silver-white frosted surface without over-corrosion.

[0...

Embodiment 2

[0043] Example 2, 0.06 g of tetra-p-sulfonate phenylporphyrin iron (III) was dissolved in 1 L of HCl solution with a concentration of 250 g / L, and 120 g of benzylamine was prepared as pickling solution, and 0.30 kg of Ti was cleaned at 80° C. -6Al-4V wire rod.

[0044] The processing steps are the same as in Example 1: soaking time of the cleaned material is 15 minutes; ultrasonic treatment is 30 s.

[0045] Processing result and control test are all the same as embodiment 1.

Embodiment 3

[0046] Embodiment 3, be the H of 200g / L in 1L concentration 2 SO 4 Dissolve 0.06 g of tetra-p-sulfonate phenylporphyrin iron (III) in the solution, and 110 g of benzylamine to prepare a pickling solution, and clean 0.33 kg of titanium wire rod at 90° C.

[0047] The processing steps are the same as in Example 1: the soaking time of the cleaned material is 35 minutes; ultrasonic treatment is 40 s.

[0048] Processing result and control test are all the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com