Anion-exchange membrane containing xanthene structure and preparation method and application of anion-exchange membrane

An anion exchange membrane and monomer technology, applied in structural parts, electrical components, circuits, etc., can solve problems such as low conductivity and poor chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

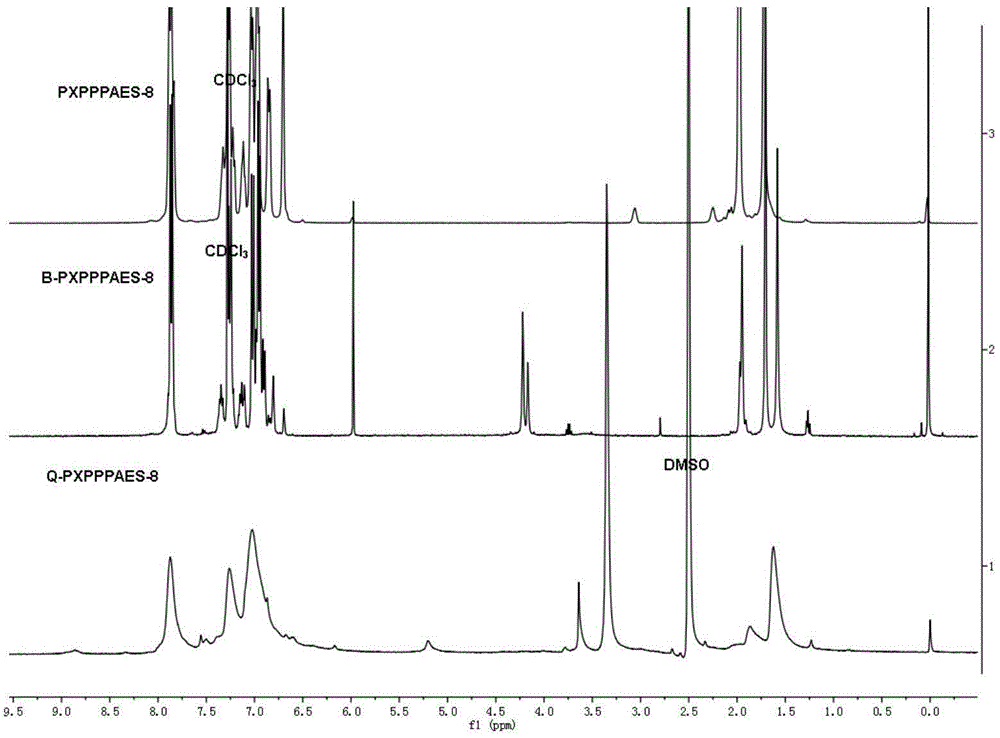

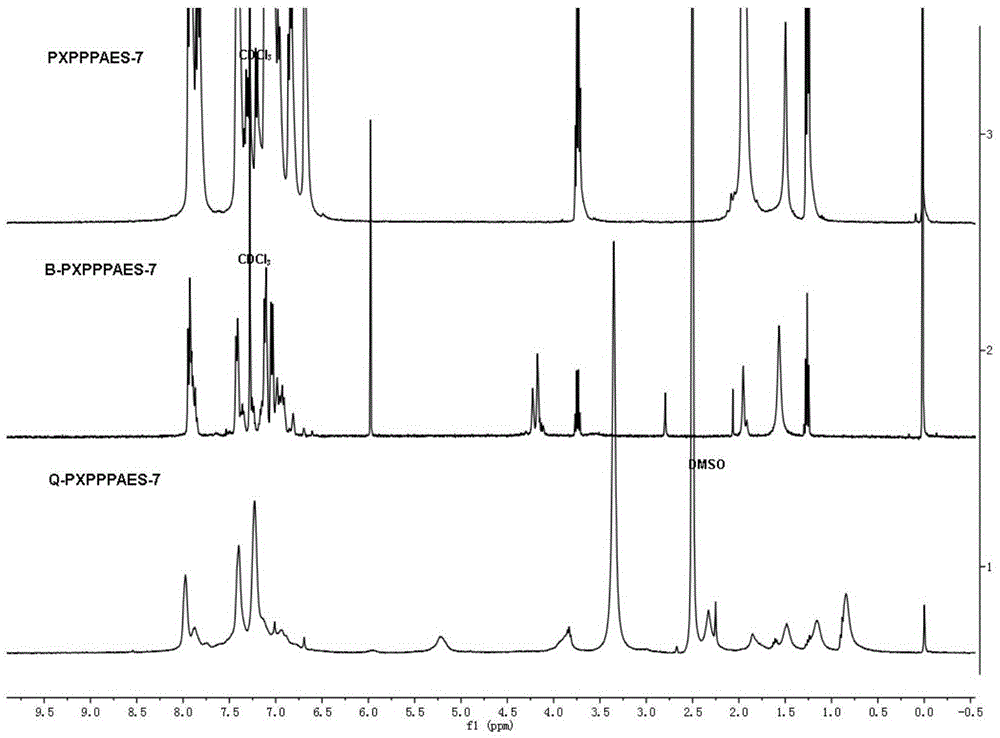

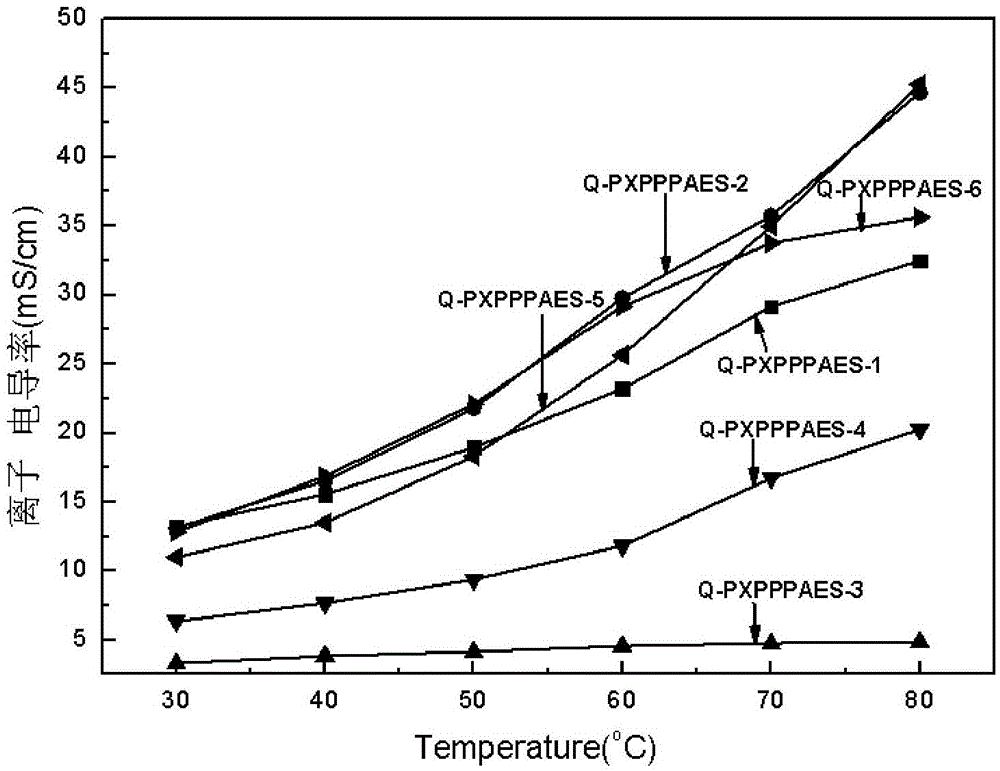

Embodiment 1

[0072] Add 5mmol of aromatic bisphenol monomer (formula II) containing a ton structure, and 5mmol of aromatic dihalogenated monomer Ar 1 (Formula 14), 5mmol of aromatic bisphenol monomer Ar 2 (Formula 12), 5mmol of aromatic dihalogenated monomer Ar 3 (Formula 14), 25mmol of potassium carbonate, 30ml of toluene and 50ml of sulfolane are added to a 250ml four-necked flask equipped with a water trap, thermometer, stirrer and nitrogen inlet and outlet. The temperature is raised to 140°C and reacted for 3h. Continue The temperature was raised to 210°C for 3 hours, the polymer solution was poured into ethanol to obtain a precipitate, washed with ethanol and deionized water 3 times, and vacuum dried at 80°C for 48 hours to obtain the polymer resin XanPAES-1; 1g polymer resin was dissolved To 20ml (31.86g) of 1,1,2,2-tetrachloroethane, add 1.27g of N-bromosuccinimide and 0.086g of benzoyl peroxide, and react at 85°C for 5h for bromine After cooling to room temperature, it was poured int...

Embodiment 2

[0075] Add 0.5 mmol of aromatic bisphenol monomer (formula II) containing a ton structure, and 0.5 mmol of aromatic dihalogenated monomer Ar 1 (Formula 15), 9.5mmol of aromatic bisphenol monomer Ar 2 (Formula 13), 9.5mmol of aromatic dihalogenated monomer Ar 3 (Formula 15), 25mmol of sodium carbonate, 20ml of toluene and 50ml of N,N-dimethylacetamide are added to a 250ml four-necked flask equipped with a water trap, thermometer, stirrer and nitrogen inlet and outlet. Heat up to 140°C for 3 hours, continue to heat up to 165°C for 12 hours, pour the polymer solution into ethanol to obtain polymer precipitation, wash it repeatedly with ethanol and deionized water for 3 times, and vacuum dry at 80°C for 48 hours to obtain polymer resin XanPAES-2; Dissolve 1g of polymer resin in 20ml (31.86g) of 1,1,2,2-tetrachloroethane, add 1.27g of N-bromosuccinimide and 0.086g of benzene peroxide Formyl, reacted at 85℃ for 5h for bromination reaction, cooled to room temperature, poured into ethan...

Embodiment 3

[0078] 9.5mmol of aromatic bisphenol monomer (formula II) containing octane structure, 9.5mmol of aromatic dihalogenated monomer Ar 1 (Formula 14), 0.5mmol of aromatic bisphenol monomer Ar 2 (Formula 12), 0.5mmol of aromatic dihalogenated monomer Ar 3 (Formula 15), 25mmol of cesium carbonate, 25ml of toluene and 50ml of N,N-dimethylformamide were added to a 250ml four-necked flask equipped with a water trap, thermometer, stirrer and nitrogen inlet and outlet. Warm up to 140°C for 3h, continue to heat up to 150°C for 20h, pour the polymer solution into ethanol to obtain polymer precipitation, wash it repeatedly with ethanol and deionized water 3 times, and vacuum dry at 80°C for 48h to obtain polymer resin XanPAES-3; Dissolve 1g polymer resin in 20ml (24.70g) 1,2-dichloroethane, add 1.27g N-bromosuccinimide and 0.0583g azobisisobutyronitrile, The bromination reaction was carried out by reacting at 80℃ for 6h. After cooling to room temperature, it was poured into ethanol for preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com