a na + 、k + 、nh 4 + 、cl ‑ 、so 4 2‑ 、no 3 ‑ Comprehensive utilization method of high-concentration waste brine in coal chemical industry

A SO42-, high-concentration waste technology, applied in chemical instruments and methods, water/sludge/sewage treatment, chemical industry, etc., can solve problems such as untreatable, high COD, unusable, etc., and achieve significant economic benefits and social benefits Benefits, reduce steam consumption, improve the effect of product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

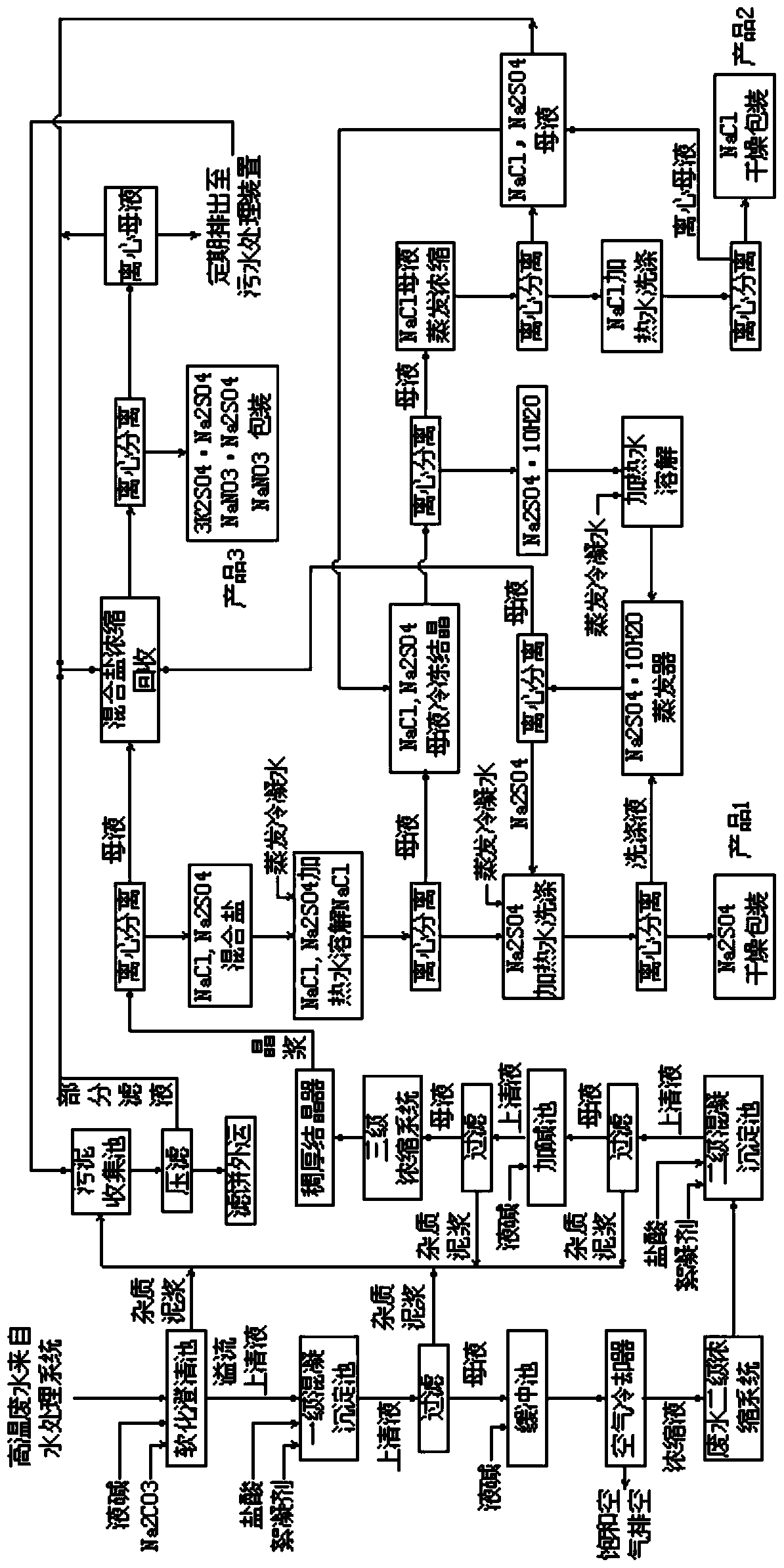

[0021] A containing Na + 、K + , NH 4 + , Cl - , SO 4 2- , NO 3 - The comprehensive utilization method of high-concentration waste brine in coal chemical industry comprises the following steps:

[0022] (1) Remove hardness. The high-concentration waste brine with a pH value of 10.5-11 (referred to as high-salt wastewater, the same below) is first pumped into the softening and clarifying tank of this system, and 42-50% (mass concentration, the same below) of liquid alkali is added to adjust the pH value to 11.5 -12, making Mg in wastewater 2+ Precipitate in the form of magnesium hydroxide; then add a small amount of sodium carbonate, according to the Ca in water 2+ The content of each waste water is added 1-1.5 kilograms, and the purity is greater than 98%, so that Ca 2+ Precipitate in the form of calcium carbonate; in order to fully precipitate, the agitator in the pool stirs slowly at a speed of 60 revolutions per minute; when magnesium hydroxide precipitates, part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com