Minocycline hydrochloride sustained release pellet and preparation method thereof

A technology of minocycline hydrochloride and sustained-release pellets, which is applied in the direction of active ingredients of tetracycline, pharmaceutical formulas, medical preparations of non-active ingredients, etc., and can solve the problems of packaging, transportation, and storage inconvenience, low drug release stability, and stomach problems. Intestinal irritation and other problems, to achieve the effect of improving bioavailability, small individual differences, and reducing irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

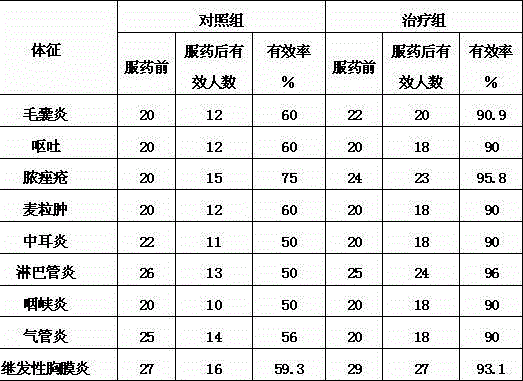

Image

Examples

Embodiment 1

[0027] A minocycline hydrochloride sustained-release pellet, comprising a coating layer and a drug-containing pellet; it is characterized in that: the coating layer is wrapped on the outside of the drug-containing pellet; the coating layer includes: 35-175mg Teqi NE30D, 5-52mg talcum powder; the drug-containing pellets include: 100mg minocycline hydrochloride, 70mg blank ball core, 50-150mg filler, 25-125mg lubricant, 5-50mg binder.

[0028] The coating layer also includes trace amounts of one or both of sodium lauryl sulfate and polyethylene glycol.

[0029] The preferred weight ratio in the coating layer is: 95mg Eudragit NE30D, 21mg talcum powder.

[0030] The preferred weight ratio of the drug-containing pellets is: 100mg of minocycline hydrochloride, 70mg of blank pellet core, 120mg of filler, 50mg of lubricant, and 10mg of binder.

[0031] The filler is microcrystalline cellulose, the lubricant is talcum powder, and the binder is hypromellose.

Embodiment 2

[0033] Its production method includes the following steps:

[0034] Step 1: Prepare materials: according to the above mass ratio, minocycline hydrochloride is pulverized with a pulverizer, and passed through a 100-mesh sieve;

[0035] Step 2: Mixing: Weigh minocycline hydrochloride and microcrystalline cellulose according to the above mass ratio, put them into a three-dimensional mixer and mix for 30 minutes to make medicine subdivisions, and take them out for later use;

[0036] Step 3: Preparation of adhesive: Weigh an appropriate amount of hypromellose according to the above mass ratio, add an appropriate amount of hot water to prepare an adhesive with a concentration of 2%, and set aside;

[0037] Step 4: Pill making: Subdivide the drug into the feed tank of the centrifugal pellet machine, put the adhesive into the liquid supply tank, put the blank pellet core into the pot, turn on the machine, adjust the parameters, and start spraying the liquid. When the ball ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com