Microbial fermentation additive and preparation method as well as application thereof

An additive and micro-storage technology, applied in the direction of bacteria used in food preparation, application, food processing, etc., can solve the problems of long fermentation time, unfavorable straw feed preparation, single bacteria secreting enzymes, and insufficient synthetic substances. It achieves the effects of making up for the deficiency of secreted enzymes and synthetic substances, having a rich and mellow smell, and a simple and practical preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] The preparation of the straw micro-storage additive comprises the following steps:

[0060] (1) Activation of bacteria

[0061] The preserved Bacillus licheniformis, Bacillus subtilis, Bifidobacterium bifidum, Enterococcus lactis, Lactobacillus acidophilus, Lactobacillus casei, Lactobacillus lactis, Lactobacillus plantarum, Pediococcus lactis, Pediococcus pentosaceae, pseudococcus utilis Trichosaccharomyces, Saccharomyces cerevisiae and Rhodopseudomonas palustris were placed in sterilized 1% sugar water and activated for 2 hours, and then the spores were transferred into the sterilized common broth medium, the lactic acid bacteria were transferred into MRS, and the yeasts were transferred into Put it into YPD slant medium, place it at 28-35°C, put it into sterilized common broth MRS and YPD medium after the colony grows, and culture it in the shaker at the same temperature as the corresponding slant medium for 24 -48h;

[0062] (2) Preparation of seed solution

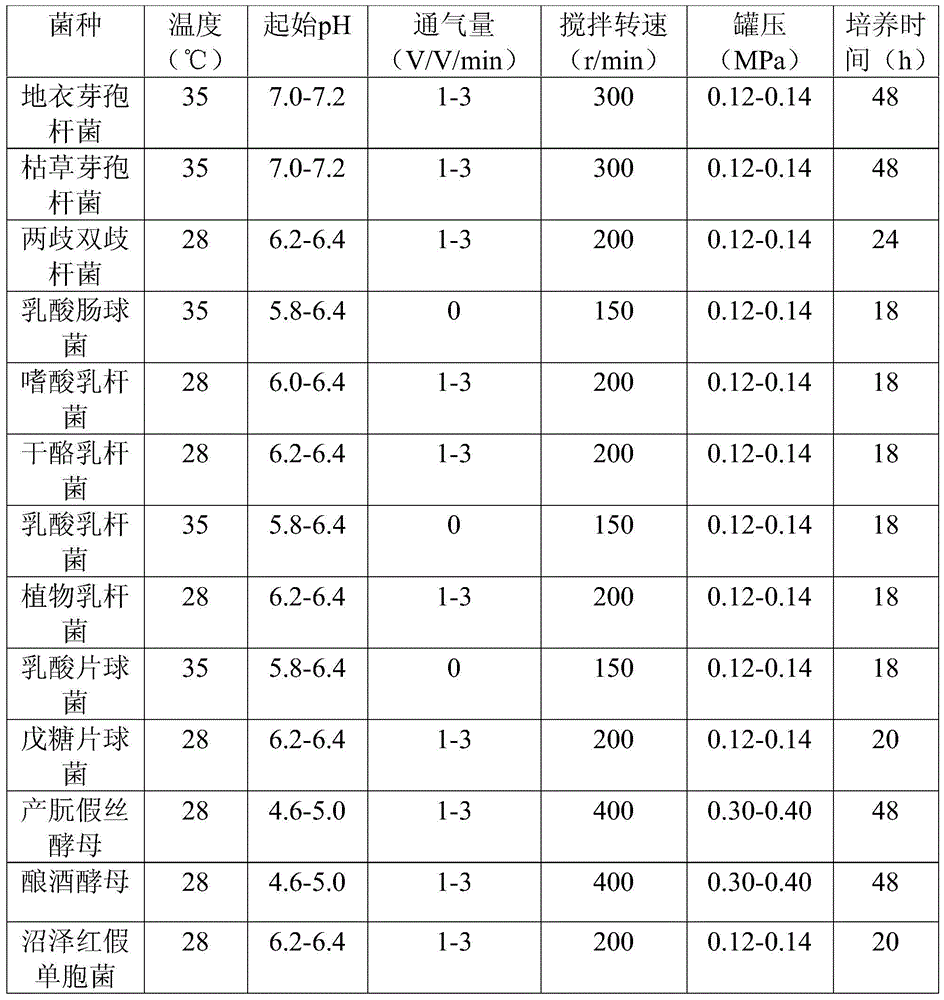

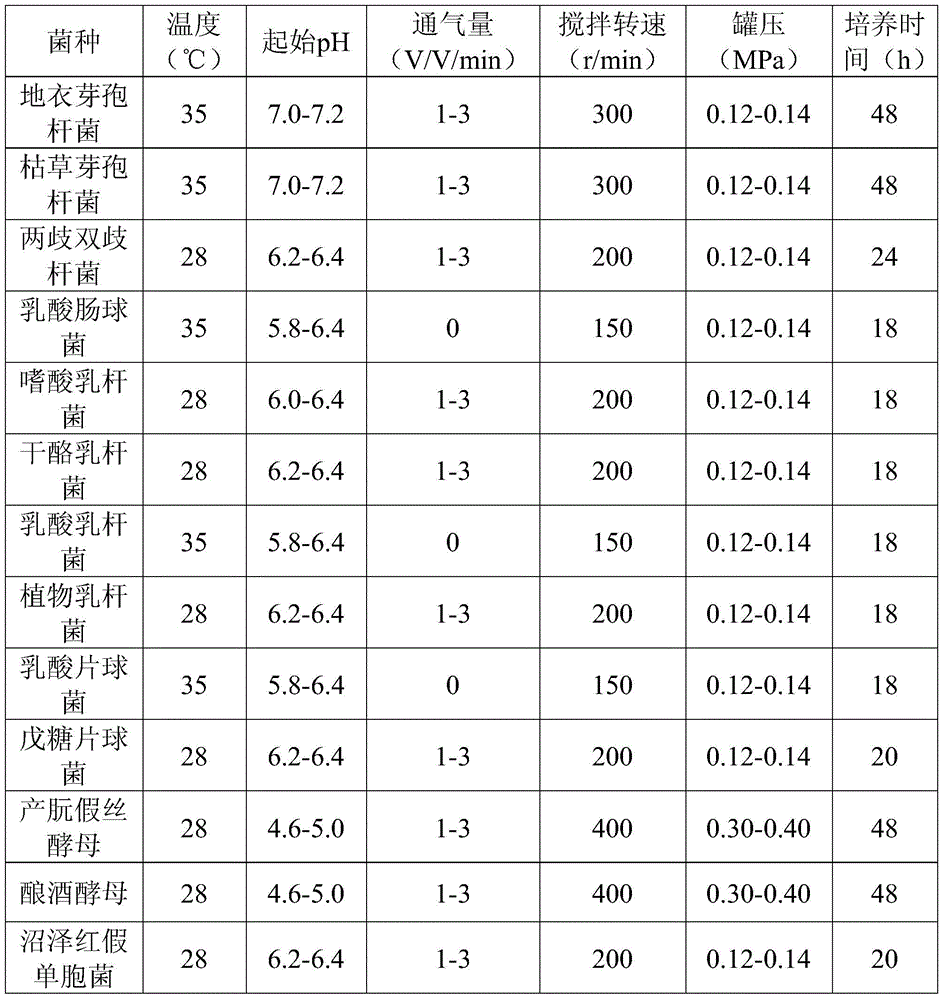

[006...

Embodiment 2

[0086] The preparation of the straw micro-storage additive comprises the following steps:

[0087] (1) Activation of bacteria;

[0088] (2) Seed solution preparation;

[0089] (3) Medium preparation and inoculation;

[0090] (4) fermentation;

[0091] (5) Bacteria collection and bacterial agent preparation; wherein, steps (1)-(5) are the same as in Example 1;

[0092] (6) The preparation of micro-storage additive comprises the following steps:

[0093] (a) Determination of the number of live bacteria per unit mass of the freeze-dried agent: Take out several grams of the preserved freeze-dried agent, quickly add 4°C pre-cooled sterile distilled water and shake at 22°C for 10 minutes to resuspend the bacteria, and count the live bacteria after doubling dilution , determine the formula for calculating the number of live bacteria in the freeze-dried agent:

[0094] W=m / (n×V 0 / V 1 )

[0095] W = number of live bacteria per unit mass, cfu / g;

[0096] m = sample mass, g;

...

Embodiment 3

[0107] The application of the prepared micro-storage additive:

[0108] (1) Prepare bacterial solution

[0109] Take 3-5 grams of live dried bacteria and activate them in 500 mL of 1% brown sugar water for 1-2 hours, add 0.9% normal saline to the revived bacteria liquid, make up to 1000 L, mix evenly, and set aside. The bacterial solution is used up on the same day and cannot be used overnight. See Table 3 for the amount of bacterial solution and treated straw.

[0110] Table 3 Bacterial Solution Mixing Ratio

[0111] straw

Straw weight (kg)

Bacteria dosage (g)

Salt consumption (kg)

Tap water consumption (L)

yellow corn stalks

1000

4

8

800

[0112] (2) Collection and pretreatment of straw

[0113] Collect mature yellow corn stalks, discard mildew and severe insect damage, and remove silt, stones, metal and other particles after air drying; cut them into 5-8cm long pieces with a kneading machine for later use.

[0114]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com