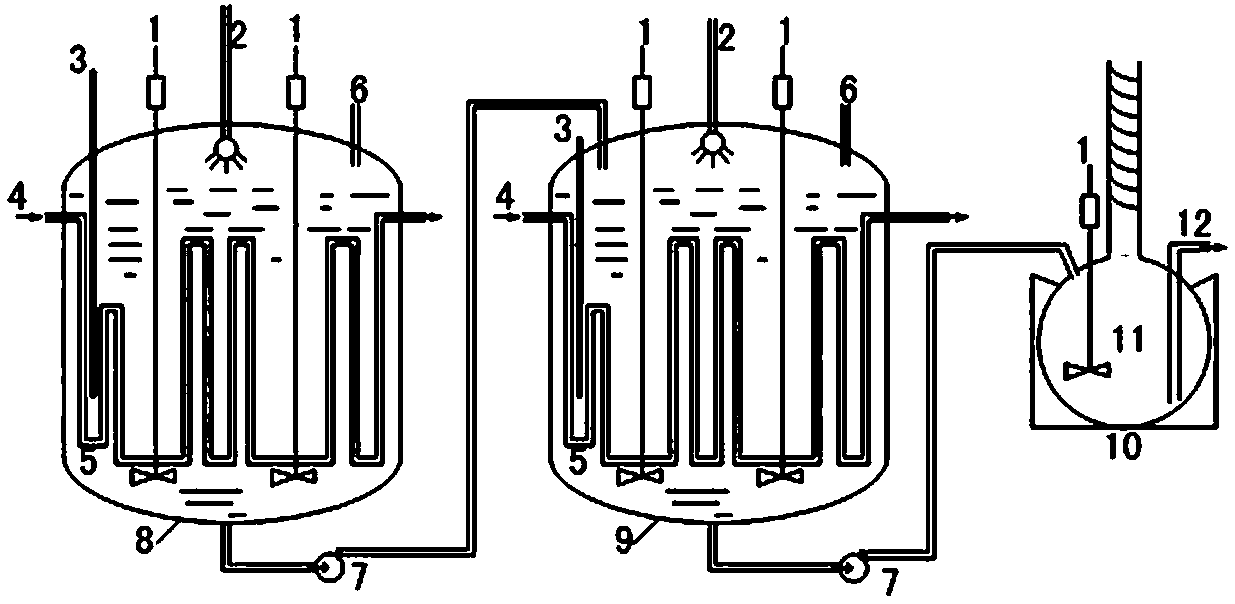

A kind of preparation method of hydroxylamine sulfate and the equipment used thereof

A technology of hydroxylamine sulfate and equipment is applied in the fields of pollution control and resource recovery and utilization, and can solve the problems of high raw material cost, complex process route and high cost of sulfur dioxide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0088] Step 1) Calcium salt conditioning: at 0 DEG C, with a concentration of 30wt% sulfuric acid solution, the pH value is 5, and the concentration of calcium bisulfite+calcium sulfite+sulfurous acid is 28wt% calcium salt suspension Adjust the pH to 1.5.

[0089] Step 2) solution cooling: the temperature of the conditioned calcium salt suspension with a pH value of 1.5 is reduced to -5°C, and the temperature of the sodium nitrite solution with a concentration of 15wt% is reduced to -5°C.

[0090] Step 3) solution mixing: the calcium salt suspension is added in the sodium nitrite solution, the mixing process is carried out under stirring, and the material ratio of the mixed solution is S in the calcium salt 4+ The molar ratio of (+4-valent sulfur) to nitrite is 2, the continuous heat exchange during the mixing process ensures that the temperature of the mixed solution is ≤0°C, and the solution temperature of the mixed solution after mixing is 0°C before adjusting the pH value....

Embodiment 2

[0095] Step 1) Calcium salt conditioning: at 0 DEG C, with a concentration of 30wt% sulfuric acid solution, the pH value is 5, and the concentration of calcium bisulfite+calcium sulfite+sulfurous acid is 28wt% calcium salt suspension Adjust the pH to 1.5.

[0096]Step 2) solution cooling: reduce the temperature of the adjusted calcium salt suspension with a pH value of 1.5 to 0°C, and reduce the temperature of the 15wt% sodium nitrite solution to 0°C.

[0097] Step 3) solution mixing: the calcium salt suspension is added in the sodium nitrite solution, the mixing process is carried out under stirring, and the material ratio of the mixed solution is S in the calcium salt 4+ The molar ratio of (+4-valent sulfur) to nitrite is 2, the continuous heat exchange during the mixing process ensures that the temperature of the mixed solution is ≤0°C, and the solution temperature of the mixed solution after mixing is -2°C before adjusting the pH value.

[0098] Step 4) Adjusting the pH v...

Embodiment 3

[0102] Step 1) Calcium salt conditioning: at 0 DEG C, with a concentration of 30wt% sulfuric acid solution, the pH value is 5, and the concentration of calcium bisulfite+calcium sulfite+sulfurous acid is 28wt% calcium salt suspension Adjust the pH to 1.7.

[0103] Step 2) solution cooling: the temperature of the adjusted calcium salt suspension with a pH value of 1.7 is lowered to -1°C, and the temperature of the sodium nitrite solution with a concentration of 15wt% is lowered to -1°C.

[0104] Step 3) solution mixing: the calcium salt suspension is added in the sodium nitrite solution, the mixing process is carried out under stirring, and the material ratio of the mixed solution is S in the calcium salt 4+ The molar ratio of (+4-valent sulfur) to nitrite is 2, the continuous heat exchange during the mixing process ensures that the temperature of the mixed solution is ≤0°C, and the solution temperature of the mixed solution after mixing is -1°C before adjusting the pH value. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com