Low-TVOC polyurethane weather-proof sealant and preparation method thereof

A polyurethane and sealant technology, applied in the field of sealants, can solve the problems of high TVOC content, difficulty in meeting the standards of car manufacturers, and high odor, and achieve the effects of simple preparation method, outstanding weather resistance, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

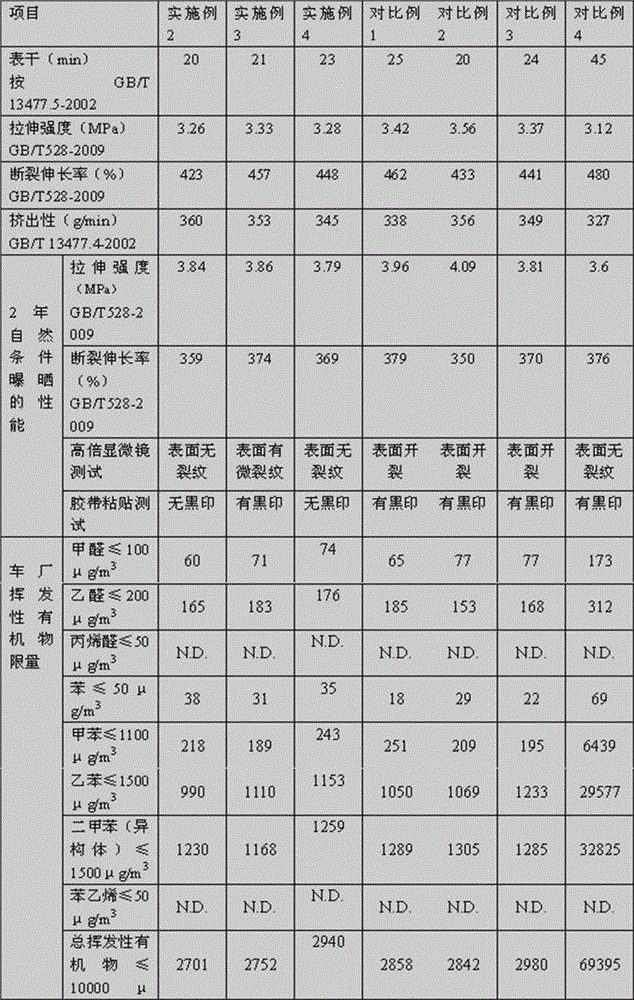

Examples

Embodiment 1

[0066] A low TVOC polyurethane weather-resistant sealant, which comprises the following components by weight percentage:

[0067] Polyurethane prepolymer 20% ~ 40%

[0068] Environmental diluent 15% ~ 40%

[0069] Compound stabilizer 0.3%~2%

[0070] Filler 30%~60%

[0071] Curing accelerator 0.3%~2%

[0072] Adhesion promoter 0.3%~2%

[0073] Water remover 0.3%~2%

[0074] Thixotropic agent 0.5% ~ 25%;

[0075] Wherein, the polyurethane prepolymer is made of the following components by weight percentage:

[0076] Polyether polyol 60%~88%

[0077] Isocyanate 10%~30%

[0078] Catalyst 0.1%~2.0%

[0079] Environmental diluent 0.5% ~ 8%;

[0080] Among them, the compound stabilizer is compounded by antioxidant, ultraviolet absorber and light stabilizer through a certain ratio, and the mass ratio of antioxidant, ultraviolet absorber and light stabilizer is 2~3:2~3 :1.

[0081] Among them, the antioxidant is one or more mixtures of hindered phenols, aromatic secondary a...

Embodiment 2

[0099] A low TVOC polyurethane weather-resistant sealant is prepared as follows: add 280g of polyurethane prepolymer P1, 10g of p-toluenesulfonyl isocyanate, and 6g of γ-(2,3-epoxypropoxy)propyltrimethoxy to a planetary stirring tank base silane, 12g compound stabilizer A (triethylene glycol bis-[3-(3-tert-butyl-4-hydroxyl-5-methylphenyl) propionate], 2-hydroxyl-4-octyloxy The mass ratio of benzophenone and the composite light stabilizer TinuvinPUR866 produced by BASF in Germany is 2:2:1), after stirring evenly, add pre-dried Benzoflex9-88180g, ground calcium carbonate 245g, nano 32g of zinc oxide, 110g of weather-resistant carbon black, 90g of polyamide wax powder, and 25g of fumed silica were stirred evenly under vacuum, and the vacuum was released with dry nitrogen, and 10g of dibutyltin dilaurate was added, then vacuumized and stirred evenly, and discharged , that is, to prepare low TVOC polyurethane weather-resistant sealant.

Embodiment 3

[0101]A low TVOC polyurethane weather-resistant sealant is prepared as follows: use 12g compound stabilizer B (tris(2,4-di-tert-butylphenyl) phosphite, 2-(2'-hydroxyl-3'-tert-butyl The mass ratio of -5'-methylphenyl)-5-chlorobenzotriazole and bis(1,2,2,6,6-pentamethyl-4-piperidinyl) sebacate is 2:2:1) Instead of 12g of compound stabilizer A, the other components are the same as in Example 2, and the similar steps as in Example 2 are repeated to obtain a low TVOC polyurethane weather-resistant sealant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of unsaturation | aaaaa | aaaaa |

| degree of unsaturation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com