Hydrothermal preparation method of Sb2S3 semiconductor film with narrow band gap

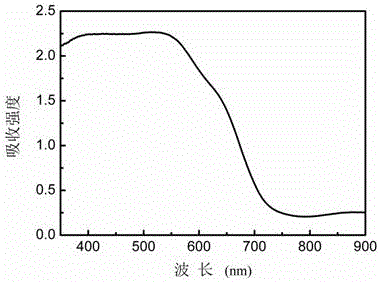

A semiconductor, narrow bandgap technology, applied in the field of hydrothermal preparation of Sb2S3 semiconductor thin films, can solve the problems of large environmental pollution, unstable system, reduced solar light absorption efficiency, etc., and achieve the effect of good crystallinity and uniform and continuous thin film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Weigh 0.334gKSbC in sequence 4 h 4 o 7 1 / 2H 2 O, 0.496gNa 2 S 2 o 3 ·5H 2 O (the reagents used are all analytical grade, the molar ratio is 10:20) was dissolved in 100mL aqueous solution, stirred evenly and then ultrasonicated for 5min.

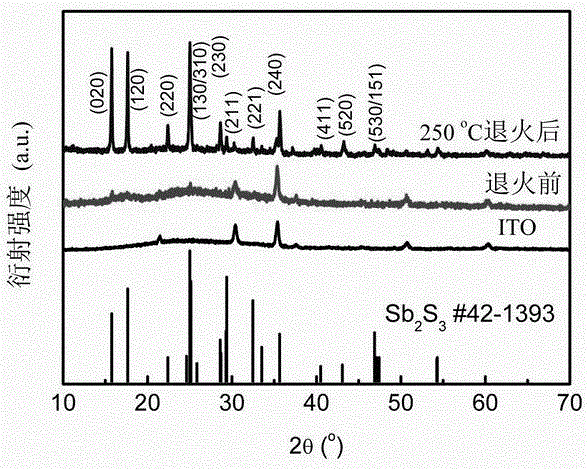

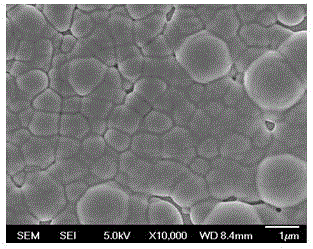

[0031] 2) Transfer the solution prepared in step 1) to the polytetrafluoroethylene liner of the hydrothermal kettle, use the pretreated ITO glass as the base, place its conductive side down, and place it obliquely in the polytetrafluoroethylene liner middle. After sealing the hydrothermal kettle and the polytetrafluoroethylene liner, the temperature of the hydrothermal kettle is controlled at 150oC, and the hydrothermal time is controlled at 8h to obtain orange-red Sb with good adhesion. 2 S 3 semiconductor film. figure 1 X-ray diffraction results show that the film has only weak Sb 2 S3 diffraction peaks, indicating its poorly crystalline structure.

[0032] 3) Under the condition of argon protection, the above Sb 2 S ...

Embodiment 2

[0034] 1) Weigh 0.334gKSbC in sequence 4 h 4 o 7 1 / 2H 2 O, 0.496gNa 2 S 2 o 3 ·5H 2 O (the reagents used are all analytical grade, the molar ratio is 10:20) was dissolved in 100mL aqueous solution, stirred evenly and then ultrasonicated for 5min.

[0035] 2) Transfer the solution prepared in step 1) to the polytetrafluoroethylene liner of the hydrothermal kettle, use the pretreated ITO glass as the substrate, place its conductive side down, and place it obliquely in the polytetrafluoroethylene liner middle. After sealing the hydrothermal kettle and the polytetrafluoroethylene liner, the temperature of the hydrothermal kettle is controlled at 150oC, and the hydrothermal time is controlled at 8h to obtain orange-red Sb with good adhesion. 2 S 3 semiconductor film.

[0036] 3) Under the condition of argon protection, the above Sb 2 S 3 The semiconductor film was placed in a tube furnace at a constant temperature of 450°C for 60 minutes, and then the film was taken out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com