Flame-retardant masterbatch, flame-retardant masterbatch based phosphorus-nitrogen intumescent flame-retardant material and preparation method thereof

A flame-retardant masterbatch and flame-retardant material technology, which is applied in the field of halogen-free intumescent flame-retardant materials, can solve the problems of flame-retardant materials such as reduced mechanical properties, low relative molecular weight, easy migration or precipitation, etc., to reduce hygroscopicity, Reduced dosage, excellent anti-separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

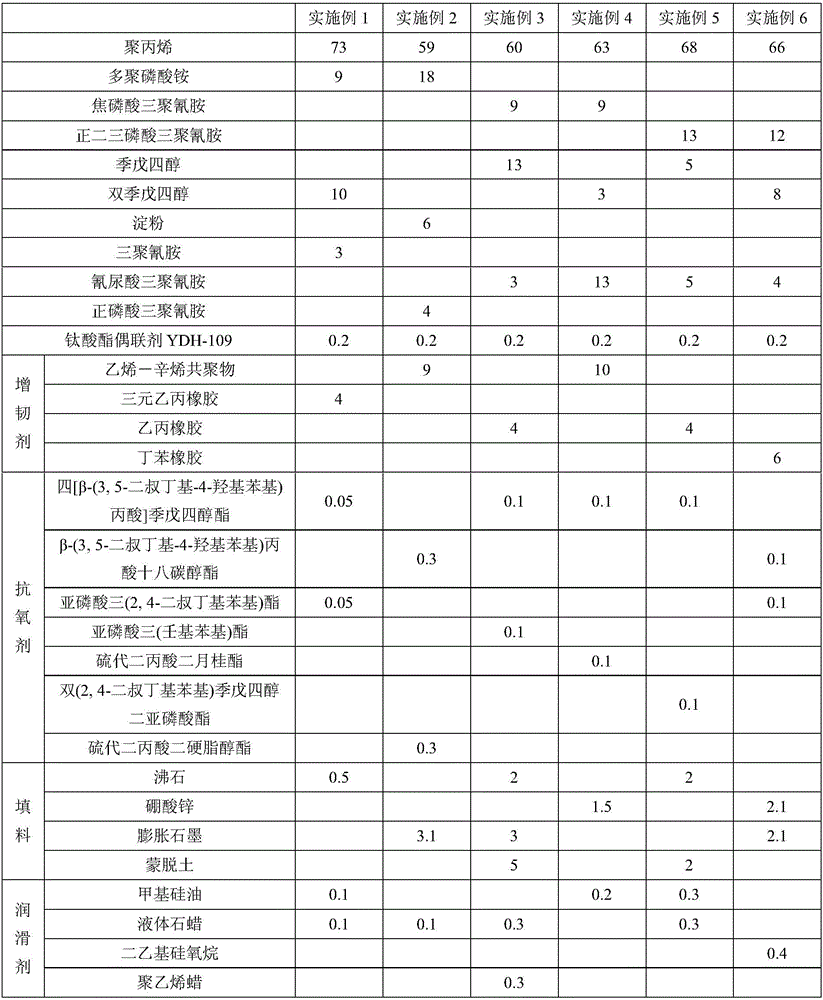

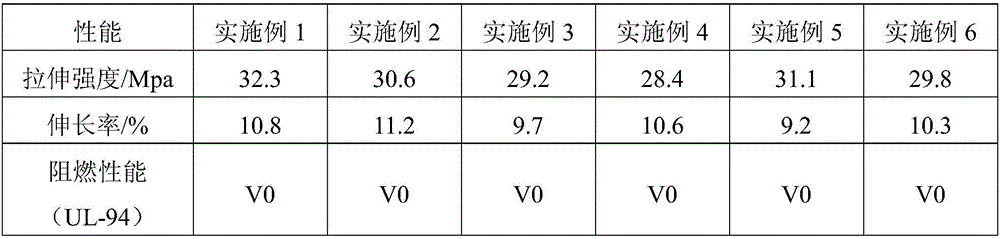

[0036] The phosphorus-nitrogen intumescent flame retardant material of the present invention includes polyolefin resin, phosphoric acid compound, multi-carbon polyhydroxy compound, nitrogen-containing multi-carbon compound, coupling agent, toughening agent, antioxidant, filler and lubricant.

[0037] Each component is polypropylene: 73%; ammonium polyphosphate: 9%; dipentaerythritol: 10%; melamine: 3%; titanate coupling agent YDH-109: 0.2%; : 4%; tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester: 0.05%; tris (2,4-di-tert-butylphenyl) phosphite: 0.05%; Zeolite: 0.5%; Methyl silicone oil: 0.1%; Liquid paraffin: 0.1%.

[0038] The manufacturing method steps are:

[0039] a: Ammonium polyphosphate, dipentaerythritol and melamine were air-dried at 100°C for 3 hours;

[0040]b: Weigh the dried ammonium polyphosphate, dipentaerythritol and melamine according to the weight ratio, add titanate coupling agent YDH-109 and appropriate amount of polypropyl...

Embodiment 2

[0045] The phosphorus-nitrogen intumescent flame retardant material of the present invention includes polyolefin resin, phosphoric acid compound, multi-carbon polyhydroxy compound, nitrogen-containing multi-carbon compound, coupling agent, toughening agent, antioxidant, filler and lubricant.

[0046] The mass percentage of each component is polypropylene: 59%; ammonium polyphosphate: 18%; starch: 6%; melamine orthophosphate: 4%; titanate coupling agent YDH-109: 0.2%; Alkene copolymer: 9%; β-(3,5-di-tert-butyl-4-hydroxyphenyl) octadecyl propionate: 0.3%; Distearyl thiodipropionate: 0.3%; Expanded graphite: 3.1%; liquid paraffin: 0.1%.

[0047] The manufacturing method steps are:

[0048] a: Ammonium polyphosphate, starch, and melamine orthophosphate were air-dried at 100°C for 3 hours;

[0049] b: Weigh the dried ammonium polyphosphate, starch and melamine orthophosphate according to the weight ratio, add titanate coupling agent YDH-109 and appropriate amount of polypropylene...

Embodiment 3

[0054] The phosphorus-nitrogen intumescent flame retardant material of the present invention includes polyolefin resin, phosphoric acid compound, multi-carbon polyhydroxy compound, nitrogen-containing multi-carbon compound, coupling agent, toughening agent, antioxidant, filler and lubricant.

[0055] The mass percentage of each component is polypropylene: 60%; melamine pyrophosphate: 9%; pentaerythritol: 13%; melamine cyanurate: 3%; titanate coupling agent YDH-109: 0.2%; 4%; Tetrakis[β-(3,5-di-tert-butyl-4-hydroxyphenyl)propionate] pentaerythritol: 0.2%; Tris(nonylphenyl) phosphite: 0.2%; Zeolite: 2% ; Expanded graphite: 3%; Montmorillonite: 5%; Polyethylene wax: 0.2%; Liquid paraffin: 0.2%.

[0056] The manufacturing method steps are:

[0057] a: Melamine pyrophosphate, pentaerythritol and melamine cyanurate were air-dried at 100°C for 6 hours;

[0058] b: Weigh the dried melamine pyrophosphate, pentaerythritol and melamine cyanurate according to the weight ratio, add titan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com