Method for producing hawthorn vinegar by hawthorn sugary liquor

A technology of hawthorn sugar and hawthorn vinegar, which is applied in the fields of food processing and biological fermentation, can solve the problems of single taste, less flavor substances, and long fermentation cycle, and achieve the effects of low process cost, short production cycle, and improved taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

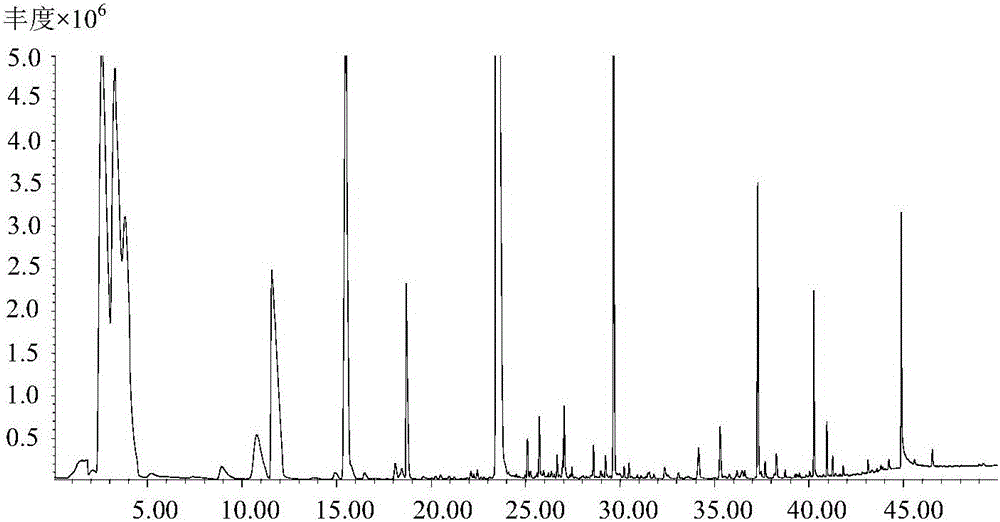

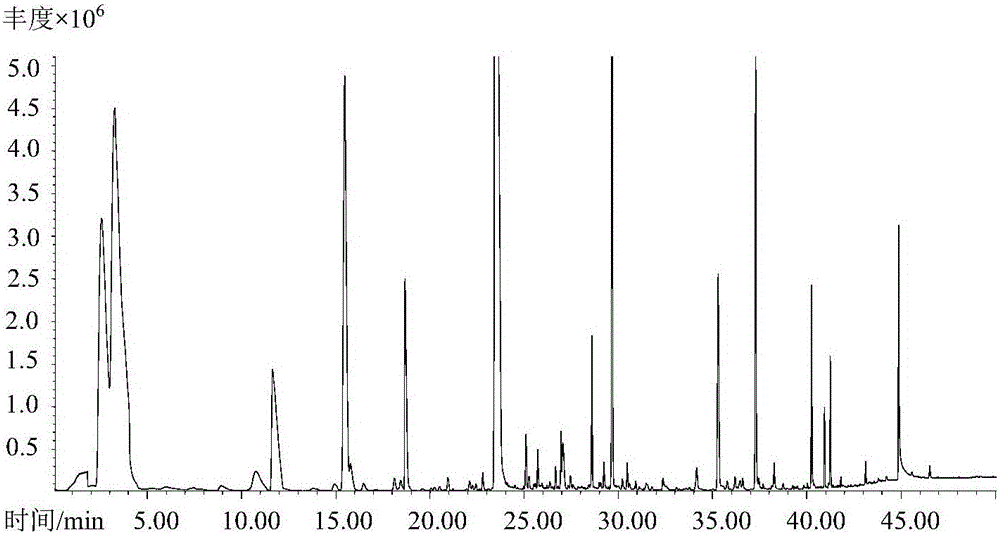

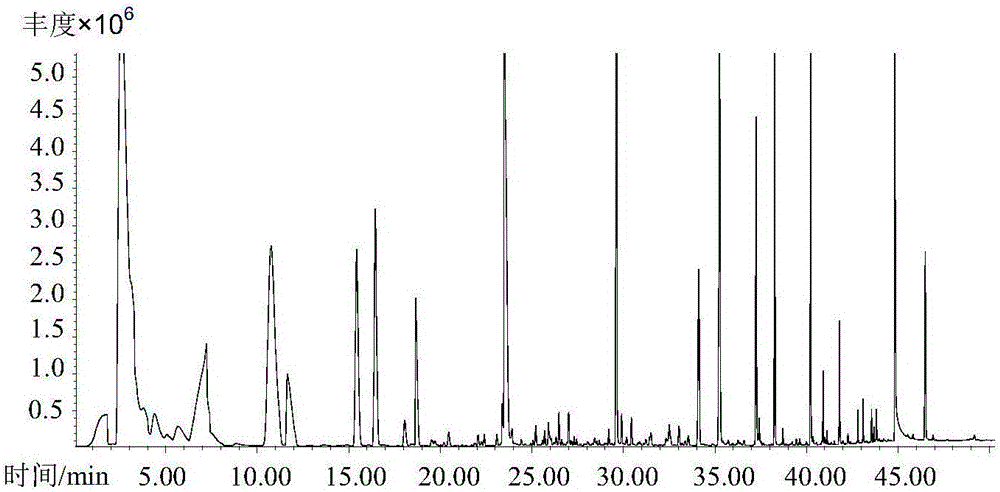

Image

Examples

Embodiment 1

[0025] Take 200mL of hawthorn sugar solution, dilute it with water until the sugar content is 15°Brix, pasteurize it at 65°C for 30 minutes, and obtain the initial sugar solution for alcohol fermentation; then add 0.08wt% activated Angel wine active dry yeast RV171, cider Yeast 1750 and Angie Aroma Yeast, the mass ratio of the three added is 5:3:2, cultivated in a constant temperature incubator at 25°C for 6 days to make hawthorn fruit wine; then add 15°Brix hawthorn syrup to adjust the sugar content to reach 8°Brix, insert 6wt% expanded Acetobacter AS1.41, adjust the pH to 3.5 with 1mol / L NaOH solution, and ferment for 5 days in a constant temperature shaking table with a rotation speed of 100r / min at 25°C, and the fermentation broth Pasteurize at 65° C. for 30 minutes, filter after cooling, add 1.5 wt % edible salt, and age at room temperature for 30 days to obtain hawthorn vinegar. Total acid 1.8g / 100mL; reducing sugar 1.42g / 100mL; soluble solids 5.1%; pH3.08.

[0026] Usi...

Embodiment 2

[0028] Take 200mL of hawthorn syrup, dilute it with water until the sugar content is 15°Brix, then add 6g / L corn steep liquor dry powder, 4g / L ammonium sulfate, 0.4g / L magnesium sulfate, 70μg / L biotin, 0.1g / L Na of L 2 HPO 3 , 100mg / L CaCl 2 , 0.1mg / L FeSO 4 ·7H 2 O, pasteurized at 65°C for 30min to obtain the initial sugar solution for alcoholic fermentation; then insert 0.08wt% activated Angel wine active dry yeast RV171, cider yeast 1750 and Angelica aromatic yeast, the three added The mass ratio is 5:3:2, cultivated in a constant temperature incubator at 30°C for 6 days to obtain hawthorn fruit wine; then add 15°Brix hawthorn syrup to adjust the sugar content to 8°Brix, and then insert 6wt% of the expanded cultured Acetobacter AS1.41, 1mol / L NaOH solution to adjust the pH to 3.5, fermented at 25°C in a constant temperature shaker with a rotation speed of 100r / min for 5 days, pasteurized the fermentation liquid at 65°C for 30min, filtered after cooling, Add 1.5wt% edib...

Embodiment 3

[0031] Take 200mL of hawthorn syrup, dilute it with water until the sugar content is 15°Brix, then add corn steep liquor powder, ammonium sulfate, magnesium sulfate, biotin, Na 2 HPO 3 , CaCl 2 , FeSO 4 ·7H2 O, the addition amount of corn steep liquor dry powder is 8g / L, the addition amount of ammonium sulfate is 3g / L, the addition amount of magnesium sulfate is 0.2g / L, the addition amount of biotin is 60μg / L, Na 2 HPO 3 The amount added is 0.2g / L, CaCl 2 Adding amount is 120mg / L, FeSO 4 ·7H 2 The amount of O added is 0.3mg / L, and pasteurized at 70°C for 30 minutes to obtain the initial sugar solution of alcoholic fermentation; add 0.10wt% of activated Angel Wine Active Dry Yeast RV171, Cider Yeast 1750 and Angel Fragrance Yeast, the mass ratio of the three added is 5:3:2, cultivated in a constant temperature incubator at 30°C for 6 days to make hawthorn fruit wine; then add 15°Brix hawthorn syrup to adjust the sugar content to 8°Brix, add glutamic acid Sodium ascorbic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com