Copper sulphide/graphene composite material for negative electrode of sodium-ion battery and preparation method

A technology for sodium ion batteries and composite materials, which is applied in the field of copper sulfide/graphene composite materials for sodium ion battery negative electrode materials and its preparation, can solve the problems of difficult rate performance, electrode material damage, specific capacity decay, etc., and achieve cycle Excellent performance and rate performance, high specific capacity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

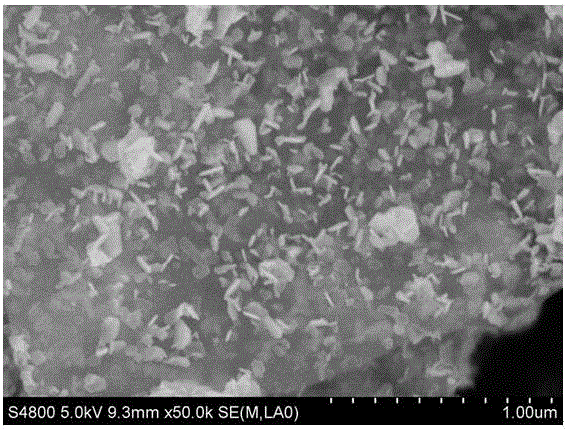

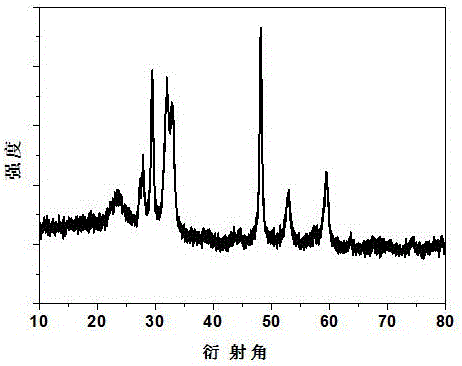

Image

Examples

Embodiment 1

[0019] First, the modified Hummer method was used to prepare graphite oxide, that is, a 250mL reaction bottle was assembled in an ice-water bath, 120mL of concentrated sulfuric acid with a mass fraction of 98% was added, and a solid mixture of 2 g of graphite powder and 1 g of sodium nitrate was added under magnetic stirring. Then slowly add 6 g of potassium permanganate, control the reaction temperature not to exceed 10 °C, take it out after stirring in an ice bath for 2 h, and stir and react at room temperature for 5 d. The sample was then treated with 5% H 2 SO 4 The solution was diluted, and after stirring for 2 h, 6 mL of H 2 o 2 , the solution turned bright yellow, stirred for 2 h and centrifuged. Then use the mass fraction of 2% H 2 SO 4 、H 2 o 2 The mixed solution and 1% HCl were washed repeatedly, and finally washed several times with distilled water to make the pH about 7, and the obtained yellow-brown solution was graphite oxide.

[0020] In the second step,...

Embodiment 2

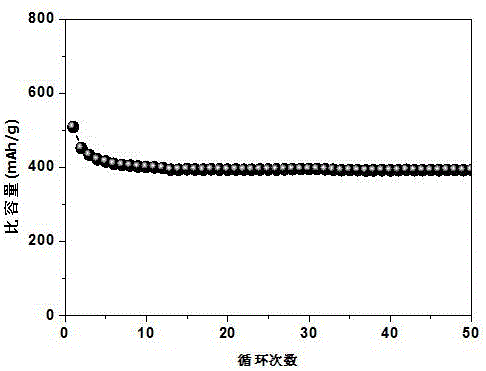

[0023] The copper sulfide / graphene composite material prepared in Example 1, the binder sodium carboxymethylcellulose and the conductive agent Super-P are dispersed in deionized water at a mass ratio of 80:10:10 to make a slurry, and evenly coated on A circular electrode with a diameter of 14mm is made on a 9μm thick copper foil after drying. Using sodium metal as the reference electrode and counter electrode, and Whatman GF / D as the separator, a CR2032 button cell was assembled in a glove box with water and oxygen content less than 0.5ppm. The 1M sodium perchlorate used was dissolved in a mixed solvent of ethylene carbonate and ethyl methyl carbonate (mass ratio 1:1), and 5% fluoroethylene carbonate was added as the electrolyte. The CR2032 button battery was charged and discharged at a constant current (0.4-2.6V) by the blue electric battery tester CT2001A, and the electrochemical performance of the copper sulfide / graphene composite material was tested.

[0024] image 3 Th...

Embodiment 3

[0026] The rate performance was tested at different current densities of 100mA / g, 250mA / g, 500mA / g, and 1000mA / g with the CR2032 button cell assembled in Example 2. Figure 4 The rate performance of the prepared copper sulfide / graphene composites at different current densities. When the current density is 1000mA / g, its specific capacity still reaches 375mAh / g, and when the current density returns to 100mA / g, its capacity can return to 400mAh / g, showing super superior rate performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inverse specific capacity | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| Specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com