High-copper feed for establishing HLD (hepatolenticular degeneration) animal model and preparation method of high-copper feed

A technology for hepatolenticular degeneration and animal model, which is applied in the field of building medical experimental animal models, can solve the problems of stimulation, low molding rate, large workload, etc., and achieves stable nutritional components, good molding effect and high success rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

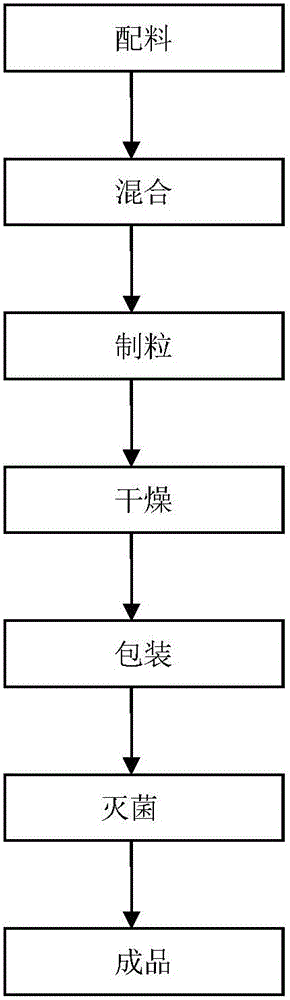

[0050] Its preparation method comprises the following steps:

[0051] 1), raw material pretreatment,

[0052] First, weigh 1% to 8% of soybean oil and 0.5% to 7% of cocoa butter, heat the soybean oil and cocoa butter to 80 to 90°C to melt, add 5% to 12% of the total weight of raw materials in water, stir evenly, and Semi-fluid grease; set aside for use;

[0053] Weigh raw materials according to proportion: casein, corn starch, maltodextrin, sucrose, cellulose, L-cystine, complex minerals, anhydrous calcium hydrogen phosphate, calcium carbonate, potassium citrate monohydrate, multivitamins and chlorine Choline;

[0054] 2), prepare the mixture,

[0055] Mix the weighed raw materials, stir evenly, add the above semi-fluid fat, and continue mixing for 2 to 4 minutes;

[0056] 3), prepare the product,

[0057] At 20-30°C, feed pellets with a diameter of 10mm and a length of 10-20mm are produced by a ring die pellet machine; at 18-25°C, the feed pellets are dehumidified and dr...

specific Embodiment 1

[0060] 1), raw material pretreatment,

[0061] First, weigh the materials in the raw materials: 1% soybean oil, 0.5% cocoa butter, heat the soybean oil and cocoa butter to 80°C to melt, add 5% of the total weight of the raw materials to the heated and melted soybean oil and cocoa butter mixture Water, stir evenly, it is a semi-fluid fat material; set aside for later use;

[0062] Weigh other materials in raw materials according to the proportion: 15% casein, 30% corn starch, 10% maltodextrin, 15% sucrose, 4% cellulose, 0.1% L-cystine, 0.5% complex minerals, Calcium hydrogen phosphate water 1%, calcium carbonate 0.2%, potassium citrate monohydrate 0.5%, multivitamin 0.5% and choline chloride 0.2%;

[0063] 2), prepare the mixture,

[0064] Mix the above-mentioned raw materials weighed, stir evenly, add the above-mentioned semi-fluid fat, and continue to mix for 2 to 4 minutes;

[0065] 3), prepare the product,

[0066] At 20-30°C, feed pellets with a diameter of 10mm and a ...

specific Embodiment 2

[0069] 1), raw material pretreatment,

[0070] First, weigh the materials in the raw materials: 8% soybean oil, 7% cocoa butter, heat the soybean oil and cocoa butter to 90°C to melt, add 12% of the total weight of the raw materials to the heated and melted soybean oil and cocoa butter mixture Water, stir evenly, it is a semi-fluid fat material; set aside for later use;

[0071] Weigh other materials in raw materials according to the proportion: 30% casein, 50% corn starch, 25% maltodextrin, 30% sucrose, 10% cellulose, 1% L-cystine, 4% complex minerals, Calcium hydrogen phosphate water 3%, calcium carbonate 1%, potassium citrate monohydrate 3%, multivitamin 3% and choline chloride 1%;

[0072] 2), prepare the mixture,

[0073] Mix the weighed raw materials, stir evenly, add the above semi-fluid fat, and continue mixing for 2 to 4 minutes;

[0074] 3), prepare the product,

[0075] At 20-30°C, feed pellets with a diameter of 10mm and a length of 10-20mm are produced by a ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com