A kind of sodium ion battery negative electrode sns/c composite material and preparation method thereof

A sodium-ion battery and composite material technology, which is applied in the field of sodium-ion battery tin sulfide and carbon composite materials and its preparation, can solve the problems of less sodium-ion batteries, immature positive and negative electrode materials and processes, and performance problems of sodium-ion batteries. Incomparable and other problems, to achieve the effect of high production efficiency, simple preparation process and high output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) 1 mmol commercialized SnS 2 Stir to dissolve in 1000 ml with a concentration of 0.1 mol L -1 A stable transparent solution is formed in the ammonium sulfide solution (the molar ratio of tin sulfide to ammonium sulfide is 0.01:1);

[0034] (2) Add 182.84 mg of PVP to the above solution to make the mass ratio of organic carbon source to tin sulfide 1:1, and stir for 600 min;

[0035] (3) blowing and drying the solution after the reaction and stirring treatment to obtain a composite material precursor;

[0036] (4) The composite material precursor was sintered at 550 °C for 1 h under nitrogen atmosphere, cooled, washed and dried to obtain the SnS / C composite material.

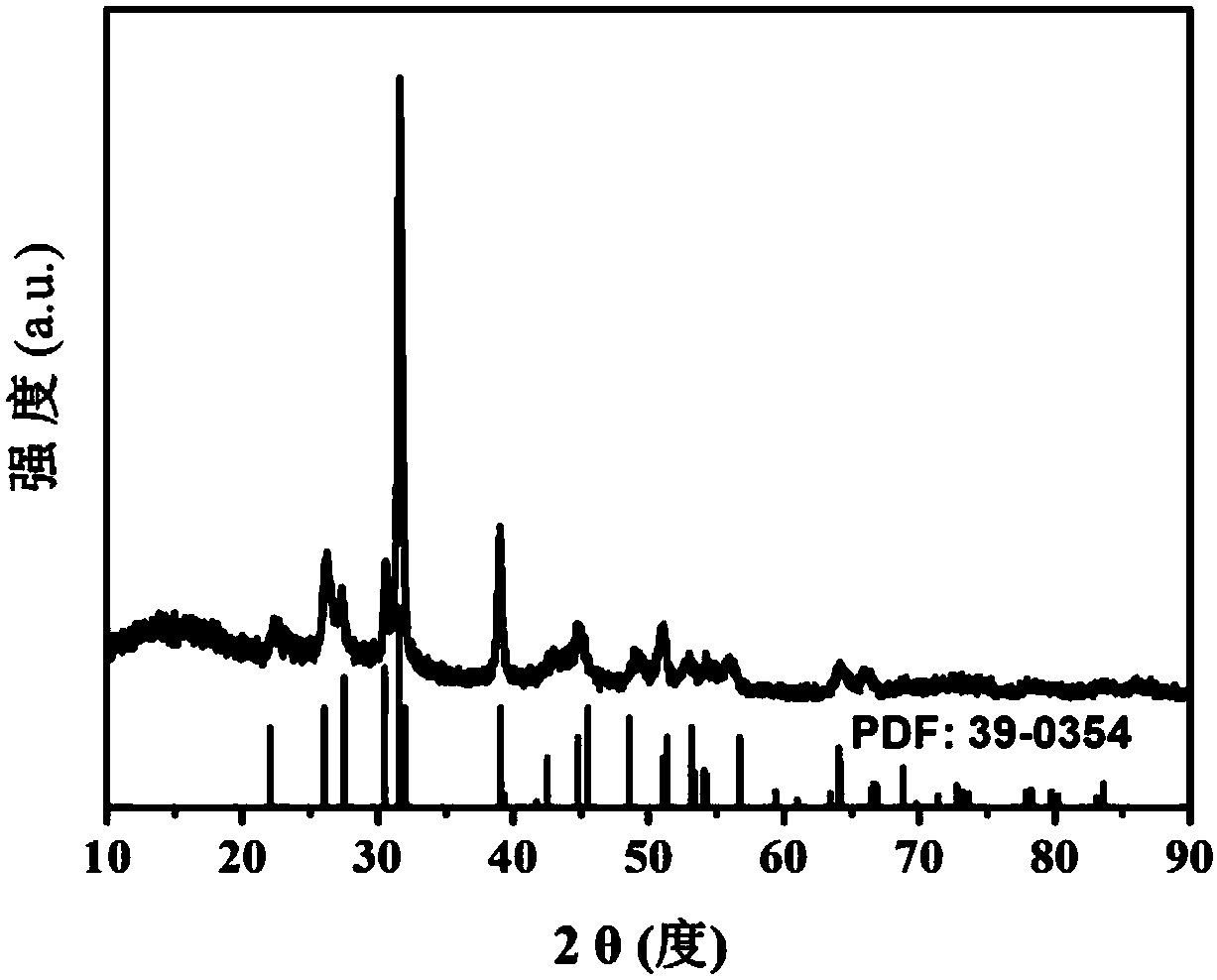

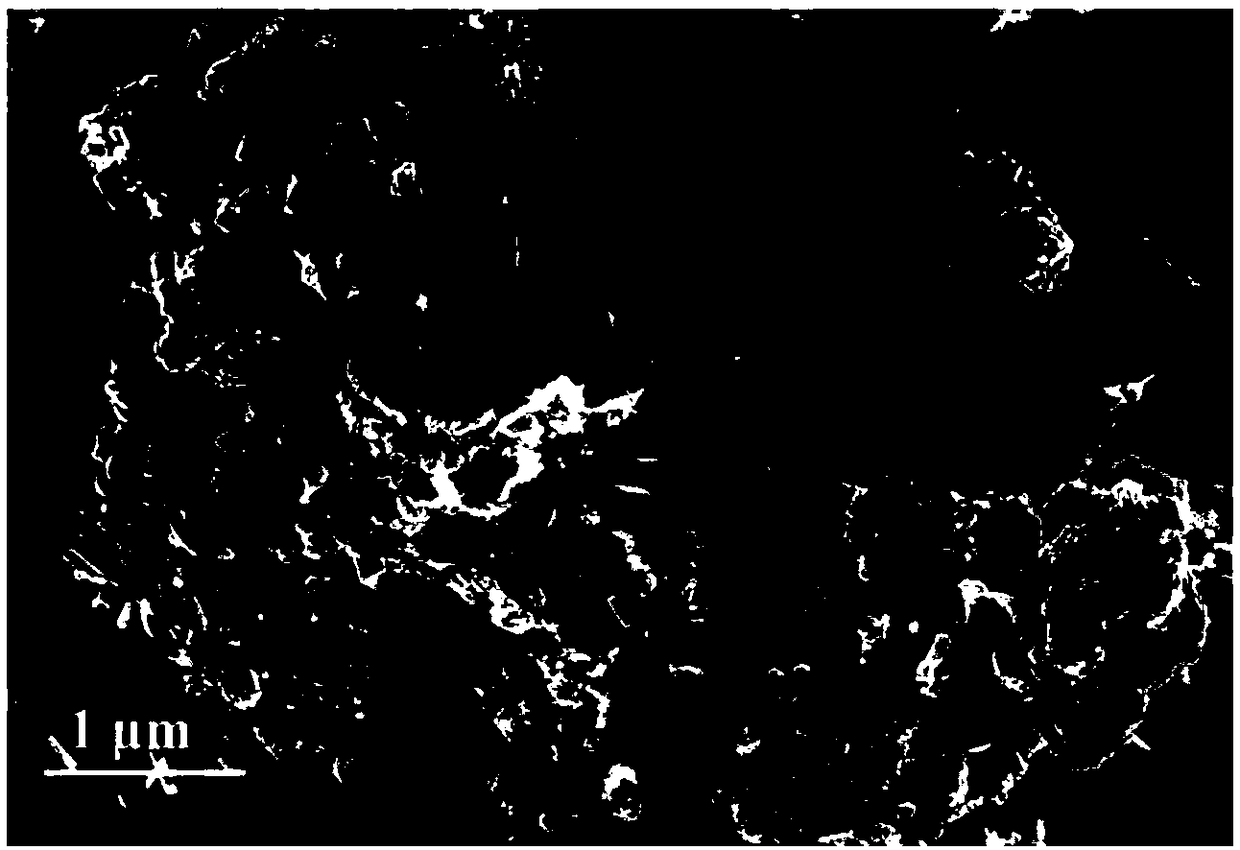

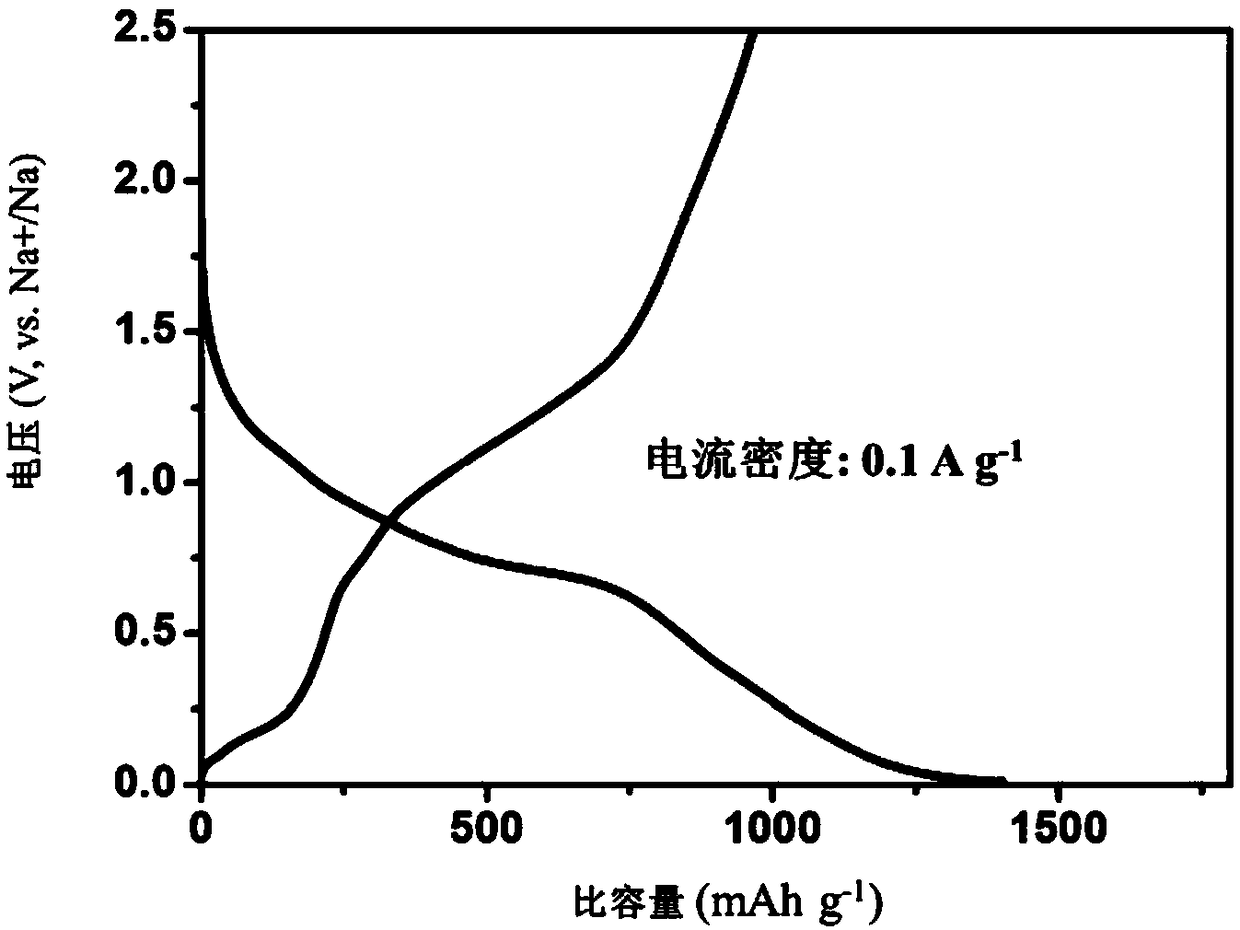

[0037] The physical and chemical properties of the prepared SnS / C composites are shown in figure 1 and figure 2 , figure 1 is the XRD spectrum of the prepared SnS / C composite, figure 2 is the SEM image of the SnS / C composite material prepared in Example 1.

[0038] XRD shows that the SnS / C mate...

Embodiment 2

[0041] (1) 0.1 mol commercial SnS 2 Stir to dissolve in 5 ml at a concentration of 5 mol L -1 A stable transparent solution is formed in the sodium sulfide solution (the molar ratio of tin sulfide to ammonium sulfide is 4:1);

[0042] (2) Add 0.182 g of glucose to the above solution so that the mass ratio of organic carbon source to tin sulfide is 0.01:1, and stir for 5 min;

[0043] (3) Freeze-drying to obtain the precursor of the composite material;

[0044] (4) The composite material precursor was sintered at 400 °C for 24 h in an argon atmosphere, cooled, washed, and dried to obtain the SnS / C composite material.

[0045] The physical and chemical properties of the prepared SnS / C material are shown in Figure 4 , Figure 5 , Figure 4 is the SEM image of the prepared SnS / C composite, Figure 4 It shows that the composite of tin sulfide and carbon is relatively uniform. The resulting SnS / C composites were assembled into coin cells, Figure 5 at a current density of 3...

Embodiment 3

[0047](1) 10 mmol of commercial SnS 2 Stir to dissolve in 2 mL with a concentration of 2.5 mol L -1 In the mixed solution of potassium sulfide and ammonium sulfide (the molar ratio of tin sulfide to ammonium sulfide is 2:1, and the molar ratio of potassium sulfide to ammonium sulfide is 1:1);

[0048] (2) Add 914.2 mg of citric acid to the above solution so that the mass ratio of organic carbon source to tin sulfide is 0.5:1, and stir for 300 minutes;

[0049] (3) Vacuum drying at 90°C to obtain the composite material precursor;

[0050] (4) Mix the composite material precursor at 3% vol. H 2 / N 2 Sintering at 475°C for 12 h in a mixed atmosphere, cooling, washing, and drying to obtain SnS / C composites.

[0051] The obtained SnS / C composite material was assembled into a button battery to measure its charge and discharge capacity, and the cycle life test was carried out in the range of 0.01-2.5V. Such as Figure 6 Shown is the rate performance of the prepared button batte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com