Three-dimensional graphene production method and apparatus, composite electrode material and preparation and application of composite electrode material

A composite electrode and graphene technology, applied in graphene, battery electrodes, chemical instruments and methods, etc., can solve the problems of high production cost, low specific capacity, and slow charging of ion batteries

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0283] According to a more specific embodiment of the present invention, the device provided by the present invention for realizing the three-dimensional graphene preparation method of the present invention can be found in Figure 9 As shown, it mainly includes: a reactor 9 for gasification reaction, an inlet system for feeding raw gas into the reactor, a feed system for feeding solid raw materials into the reactor, and a feed system for feeding the raw material gas into the reactor. The product collection system in which the gas generated by the gasification reaction is exported to the reactor and condensed for collection; where:

[0284] The reactor 9 is equipped with temperature control equipment, the middle part of the reactor 9 is a main reaction zone 10 for filling solid raw materials, the lower part of the reactor is provided with a distributor 11; the bottom of the reactor is provided with a raw material gas inlet and a solid slag outlet 12, The top is provided with an...

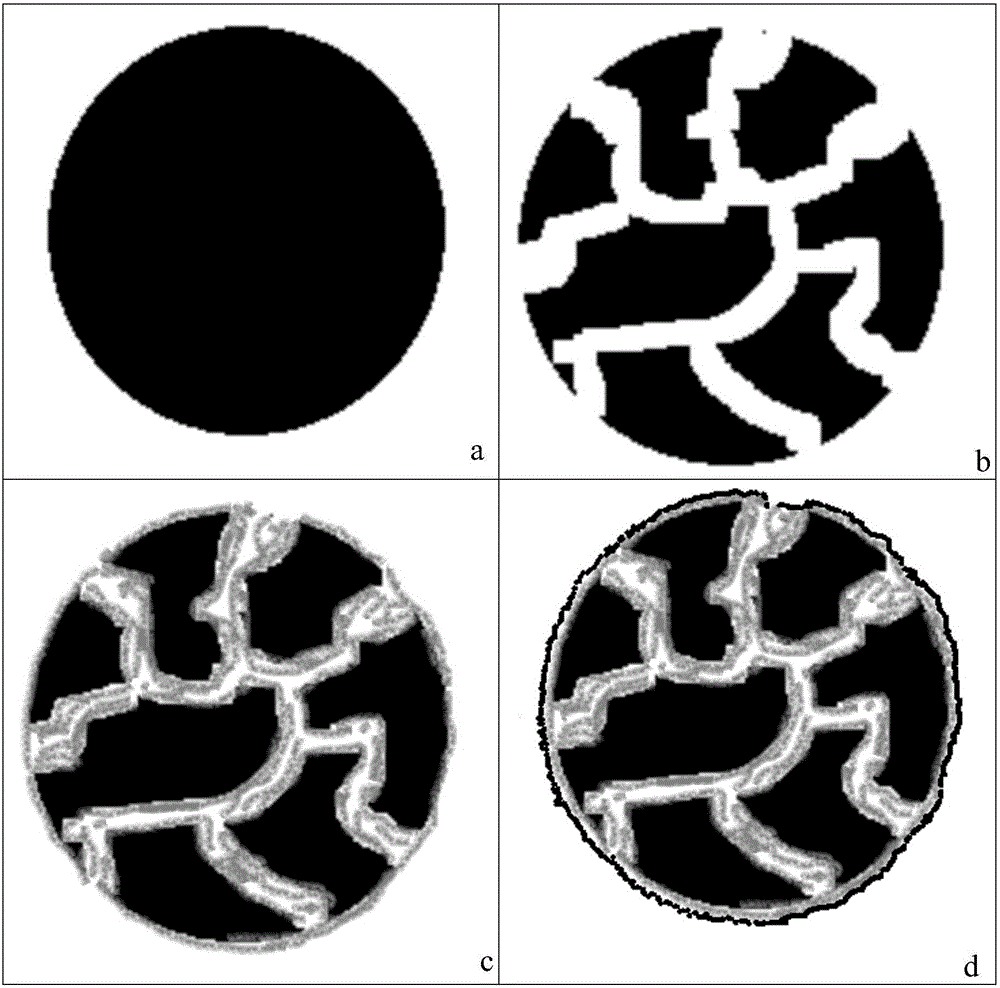

Embodiment 1

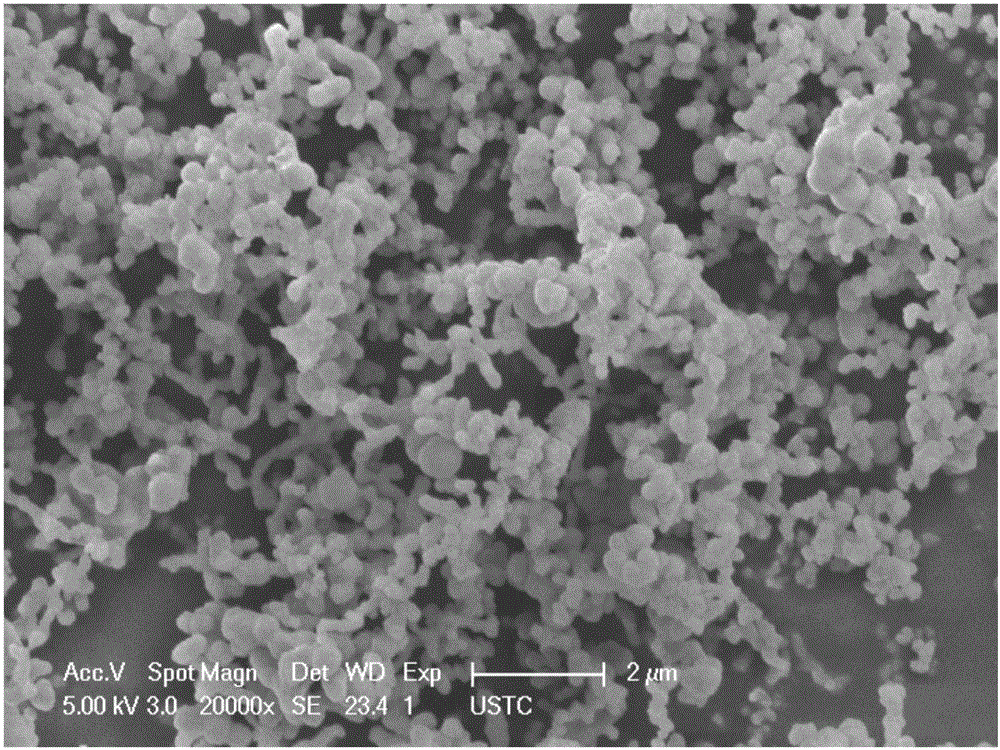

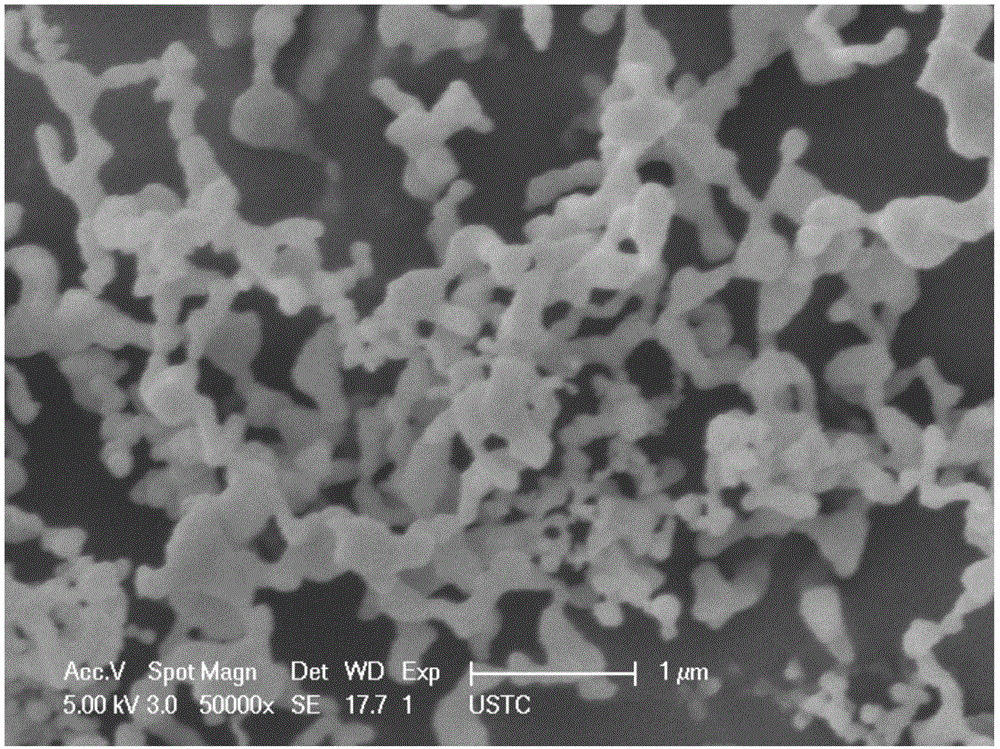

[0303] Embodiment 1: Expanded graphite produces conjoined graphene permeated silicon

[0304] This embodiment is achieved through the following steps: (1) 100 grams of expandable flake graphite (100 mesh) is placed in the reactor, heated to 600 ° C under vacuum, and the volume expands by 100 times to become Siamese graphene, and the graphene is sent to the reactor (2) feed 20 grams of silane gas (MEMC) into the reactor in (1) until the decomposition reaction is completed (stepwise method can be taken), and observe The pressure was increased to confirm completion of the reaction. Figure 2a , 2b It is the electron micrograph that the nanometer silicon that silane decomposes is attached on the graphite; (3) pass inert gas Ar into the reactor, get rid of hydrogen, the expanded graphite that is deposited with silicon in (2) is cooled to room temperature by extrusion Return to original density, silicon-containing 15% (wt); (4) silicon-containing graphite is shaped into round part...

Embodiment 2

[0309] Example 2: Preparation of graphite with high through-hole and high internal surface area by activated carbon module

[0310] This embodiment is achieved through the following steps: (1) uniformly mix 1 kg of mesophase pitch with 200 grams of high surface area activated carbon; (2) prepare the material by oxidative curing to make the mesophase a thermosetting material, and (3) allow the activated carbon to be Gasification forms a graphitizable material with through-holes; (4) high-temperature graphitization of the material containing through-holes obtained in (3) to obtain graphite with through-holes; (5) repeating the infiltration of silicon in Example 1 to surface coating The carbon-coated protective layer obtains the silicon-containing composite lithium-ion battery electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com