Radiation-proof tunnel fireproof paint

A fireproof coating and anti-radiation technology, applied in the field of coatings, can solve problems such as lack of anti-radiation and anti-fouling properties, different thermal expansion and contraction, adverse effects on physical and mental health, etc., to solve compatibility and processing problems, Large internal volume, the effect of suppressing the phenomenon of efflorescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

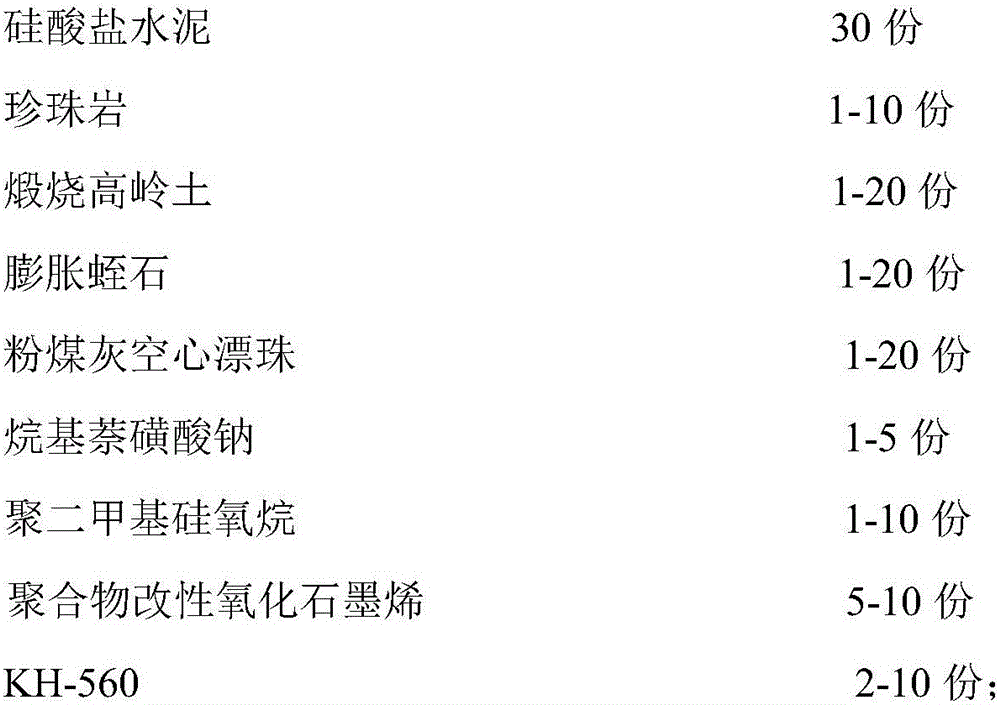

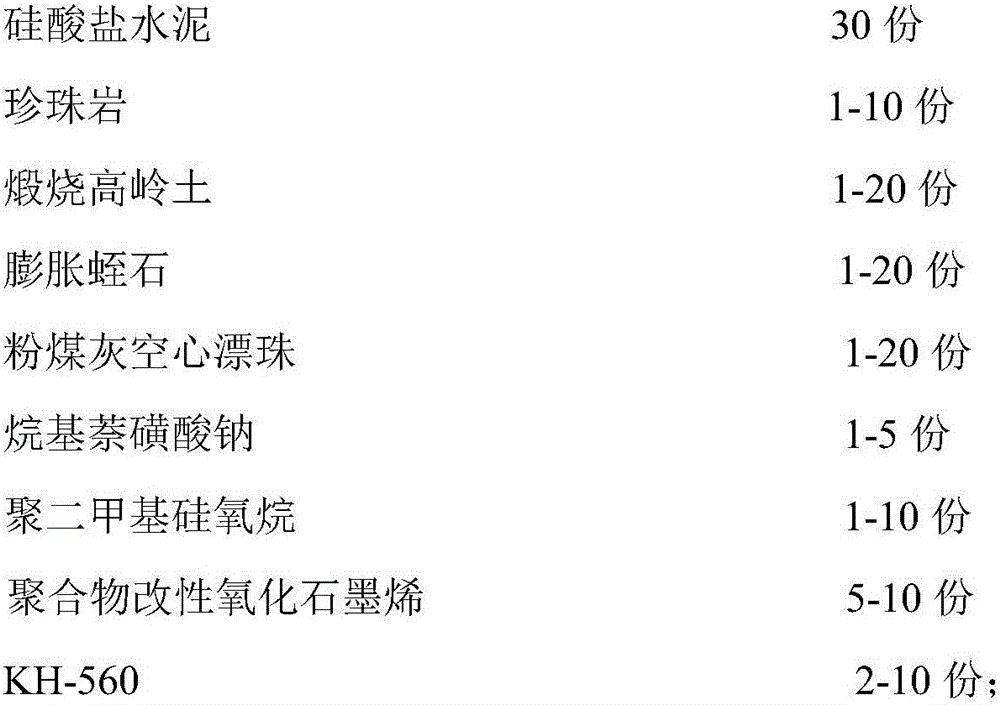

Method used

Image

Examples

preparation example Construction

[0033] H1: Polymer-modified graphene oxide, prepared by the following method:

[0034] (1) Synthesis of NTDA-terminated polypyrrolene prepolymer

[0035] In a 100mL dry three-necked flask, add 10mmol of 3,3'-diaminobenzidine DAB, 11mmol of 1,4,5,8-naphthalene tetracarboxylic anhydride NTDA, 22mmol of benzoic acid, 3mL of isoquinoline and 40mL of m-cresol, nitrogen protection and magnetic stirring; after 2 hours, heat up to 85°C for 6h, 190°C for 21h, after the reaction, cool down to 70°C and quickly pour it into 150mL methanol to obtain a large amount of solid precipitation; wash the mixture repeatedly with methanol After the product is produced, the polymer is collected by suction filtration, and dried in a vacuum oven at 160°C for 20 hours for use;

[0036] (2) Synthesis of amino-terminated sulfonated polyimide prepolymer

[0037] In a 100mL dry three-neck flask, add 1.6mmol 2,2'-bis(4-sulfophenoxy)biphenyldiamine, 12.5mL m-creso1 and 0.8mL triethylamine successively, and ...

Embodiment 1

[0059] In parts by weight, add 30 parts of A1, 8 parts of B1, 12 parts of C1, 15 parts of D1, 8 parts of E1, 3 parts of F1, 7 parts of G1, 8 parts of H1 and 5 parts of I1 into the mixer and mix well for 10 minutes , and the output is dry powder coating. According to the weight ratio, mix the powder and water according to the ratio of 1:0.5, and then coat it on the steel structure to complete the construction.

Embodiment 2

[0061] In parts by weight, add 30 parts of A1, 8 parts of B1, 12 parts of C1, 15 parts of D1, 8 parts of E1, 3 parts of F1, 7 parts of G1, 8 parts of H2 and 5 parts of I1 into the mixer and mix well for 10 minutes , and the output is dry powder coating. According to the weight ratio, mix the powder and water according to the ratio of 1:0.5, and then coat it on the steel structure to complete the construction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com