A method for synchronously extracting xylooligosaccharides and lignosulfonate from neutral sulfite pretreated plant fiber waste liquid

A technology of lignosulfonate and sulfite, which is applied in the production of oligosaccharides, chemical instruments and methods, sugar, etc., can solve the problems of synchronous extraction of lignosulfonate, achieve short production cycle, increase additional value, the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

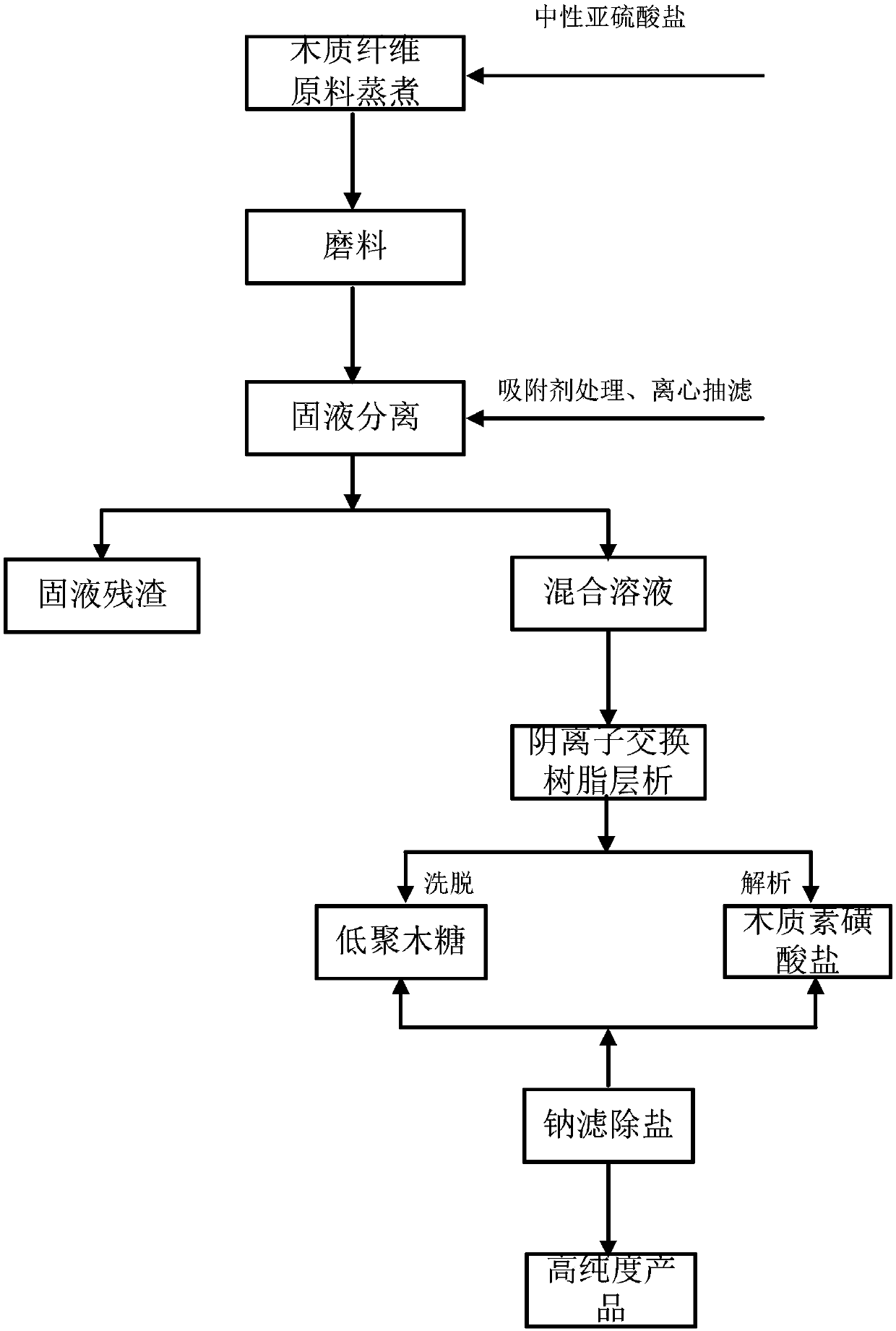

Method used

Image

Examples

Embodiment 1

[0040] Neutral magnesium bisulfite pretreats the waste liquid obtained from wheat straw, the pH value is 3.55, precipitates with 5wt‰ diatomaceous earth, centrifuges, clarifies and discards the precipitate, uses G1 sand core funnel for suction filtration, and after dilution, the liquid passes through the anion at room temperature Exchange resin D354 (Cl - type), chromatography column type: 16mm×12cm: two column volumes of the chromatography column are eluted with water, and the flow rate is 2BV / h. LNaOH+20g / L NaCl mixed solvent was used to analyze six column volumes, the flow rate was 2BV / h, and the eluate was concentrated by nanofiltration to obtain high-purity sodium lignosulfonate. The waste liquid contained 0.134 g of xylooligosaccharide and 0.758 g of lignosulfonate. After separation, 0.131 g of xylooligosaccharide was recovered from the eluent, and 0.755 g of lignosulfonate was recovered from the analysis solution. The distribution of xylooligosaccharides in the waste l...

Embodiment 2

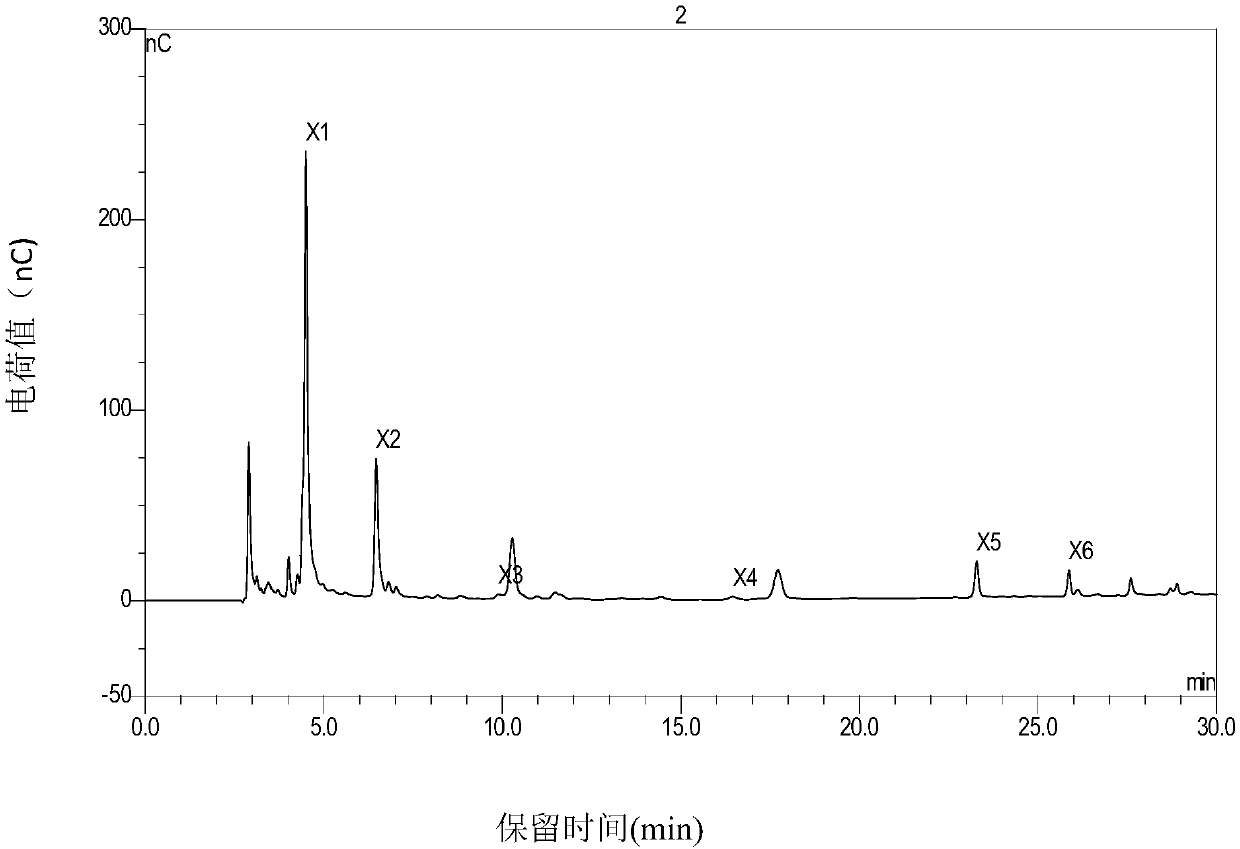

[0042] Neutral magnesium bisulfite pretreatment wheat straw waste liquid, pH value 2.61, precipitated with 5wt‰ diatomaceous earth, centrifuged, clarified and discarded, filtered with G1 sand core funnel, diluted liquid passed through anion exchange resin at room temperature D380 (Cl - type), chromatography column type: 10mm×55cm, one column volume of the chromatography column is eluted with water, and the flow rate is 1BV / h. NaOH+20g / L NaCl mixed solvent was used to analyze three column volumes, the flow rate was 2BV / h, and the eluate was concentrated by nanofiltration to obtain high-purity sodium lignosulfonate. The waste liquid contained 0.268g of xylooligosaccharides and 1.990g of lignosulfonate. After separation, 0.261g of xylooligosaccharides were recovered from the eluent, and 2.000g of lignosulfonates were recovered from the analysis solution. Ion chromatograph ICS-3000 is used for detection of xylo-oligosaccharide content, chromatographic separation conditions: colum...

Embodiment 3

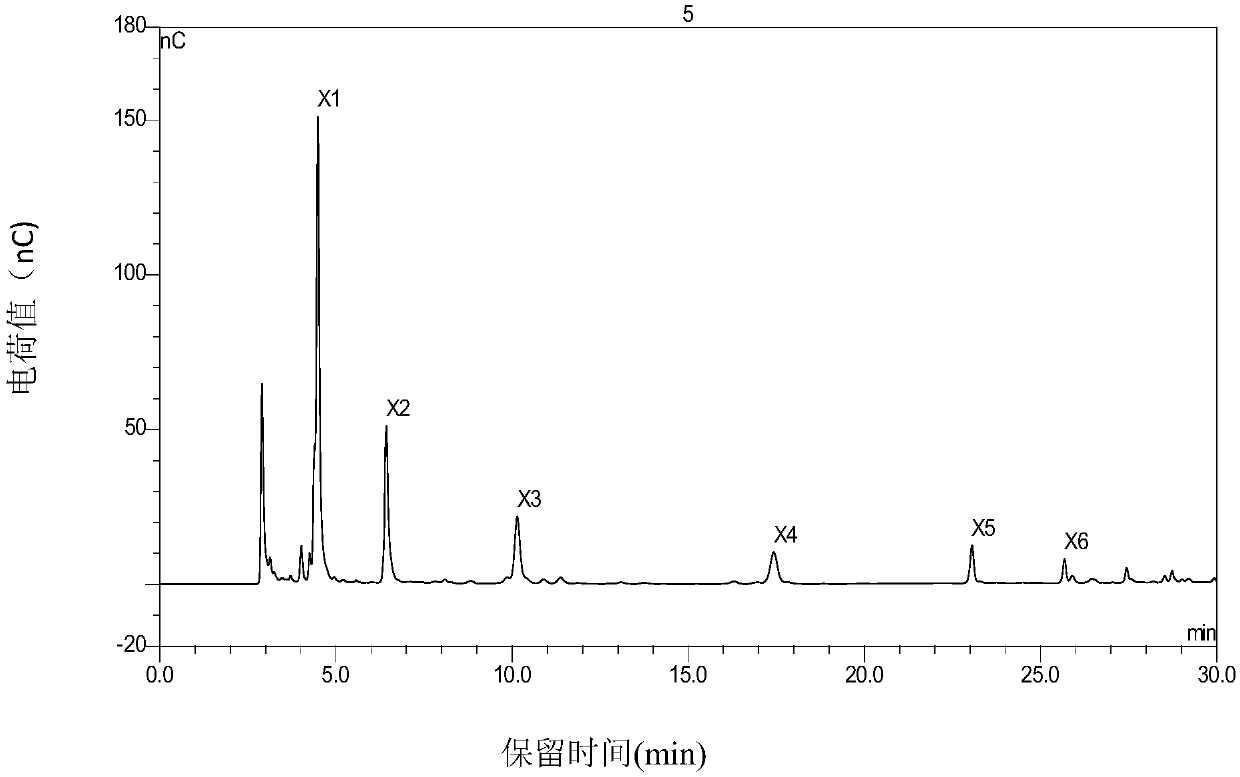

[0044] Neutral magnesium bisulfite pretreatment of wheat straw waste liquid, pretreatment conditions: 170 ℃, sealed reactor reaction for 40min, gear refiner abrasive after pretreatment, filter press for solid-liquid separation, the obtained waste liquid has a pH value of 3.63, used 5wt‰ diatomaceous earth precipitation, centrifugation, clarification and discarding the precipitation, suction filtration with G1 sand core funnel, after dilution, the liquid passes through anion exchange resin D354 (Cl - type), chromatographic column type: 16mm×12cm, two column volumes of eluted chromatographic column with water, flow rate 1BV / h, the obtained eluate is desalted by nanofiltration to obtain xylooligosaccharide solution, and the waste liquid is Contains 0.065g of xylo-oligosaccharides, and after separation, 0.063g of xylo-oligosaccharides is recovered from the eluate. Ion chromatograph ICS-3000 is used for detection of xylo-oligosaccharide content, chromatographic separation condition...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com