Novel high-performance waterproof paint

A waterproof coating, high-performance technology, applied in the direction of coating, can solve the problems of deformation, aging, breaking, etc., and achieve the effect of excellent comprehensive performance, excellent adhesion and mechanical properties, and excellent water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

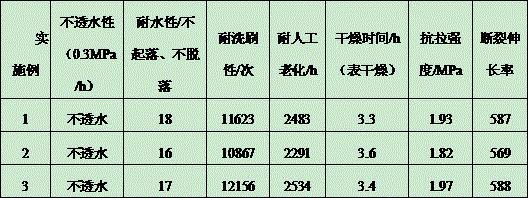

Examples

preparation example Construction

[0065] The preparation method of described novel high-performance waterproof paint, comprises the following steps:

[0066] S1: tert-butyl methacrylate, n-propyl methacrylate, tributyl citrate, ethyl methacrylate, polyethylene wax, calcium carbonate, kaolin, talc, polyester fiber, glass fiber, hydroxypropyl Methyl cellulose, bamboo charcoal fiber, degassing agent, dispersant, wetting agent, adhesion promoter, catalyst, and initiator are mixed, and the microwave power is 120-150W, the temperature is 88-95°C, and the rotation speed is 2400- Stirring at 3000r / min for 2.5-3h to prepare mixture a;

[0067] S2: Add water-based acrylic emulsion, polyacrylamide solution, drooping agent, toughening agent, brightening agent, defoamer, tackifier to the mixture a prepared in step S1, and the microwave power is 140-180W, and the temperature is Stirring at 115-125°C for 3-5 hours at a rotation speed of 400-600r / min to prepare mixture b;

[0068] S3: Add curing agent, preservative, antioxi...

Embodiment 1

[0077] A new type of high-performance waterproof coating, by weight, including the following raw materials: 120 parts of tert-butyl methacrylate, 45 parts of n-propyl methacrylate, 30 parts of tributyl citrate, and 20 parts of ethyl methacrylate , 40 parts of water-based acrylic emulsion, 30 parts of polyacrylamide solution, 30 parts of polyethylene wax, 6 parts of calcium carbonate, 5 parts of kaolin, 4 parts of talcum powder, 5 parts of polyester fiber, 4 parts of glass fiber, hydroxypropyl methyl 6 parts of cellulose, 4 parts of bamboo charcoal fiber, 0.6 part of degassing agent, 0.7 part of dispersing agent, 0.3 part of wetting agent, 0.4 part of adhesion promoter, 0.2 part of catalyst, 0.1 part of initiator, 0.5 part of weeping agent, 0.4 parts of toughening agent, 0.5 parts of brightening agent, 0.5 parts of defoamer, 0.2 parts of tackifier, 1.2 parts of curing agent, 0.2 parts of preservative, 0.2 parts of antioxidant, 0.1 part of light stabilizer, 0.2 parts of ultraviol...

Embodiment 2

[0111]A new type of high-performance waterproof coating, with weight as the unit, including the following raw materials: 105 parts of tert-butyl methacrylate, 34 parts of n-propyl methacrylate, 23 parts of tributyl citrate, and 15 parts of ethyl methacrylate , 32 parts of water-based acrylic emulsion, 24 parts of polyacrylamide solution, 20 parts of polyethylene wax, 4 parts of calcium carbonate, 3 parts of kaolin, 2 parts of talcum powder, 3 parts of polyester fiber, 3 parts of glass fiber, hydroxypropyl methyl 4 parts of cellulose, 2 parts of bamboo charcoal fiber, 0.4 part of degasser, 0.5 part of dispersant, 0.2-0. part of wetting agent, 0.3 part of adhesion promoter, 0.1 part of catalyst, 0.1 part of initiator, 0.3 part of wetting agent 0.2 parts of toughening agent, 0.3 parts of brightening agent, 0.4 parts of defoamer, 0.2 parts of tackifier, 0.8 parts of curing agent, 0.2 parts of preservative, 0.2 parts of antioxidant, 0.1 part of light stabilizer, UV absorber 0.2 par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com