Bisphenol A imprinted Pickering emulsion polymer microspheres, preparation and applications thereof

A Pickering emulsion and polymer technology, applied in the fields of biological analysis and new materials, to achieve high adsorption capacity and selectivity, reduce matrix interference, and ultra-high specific selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

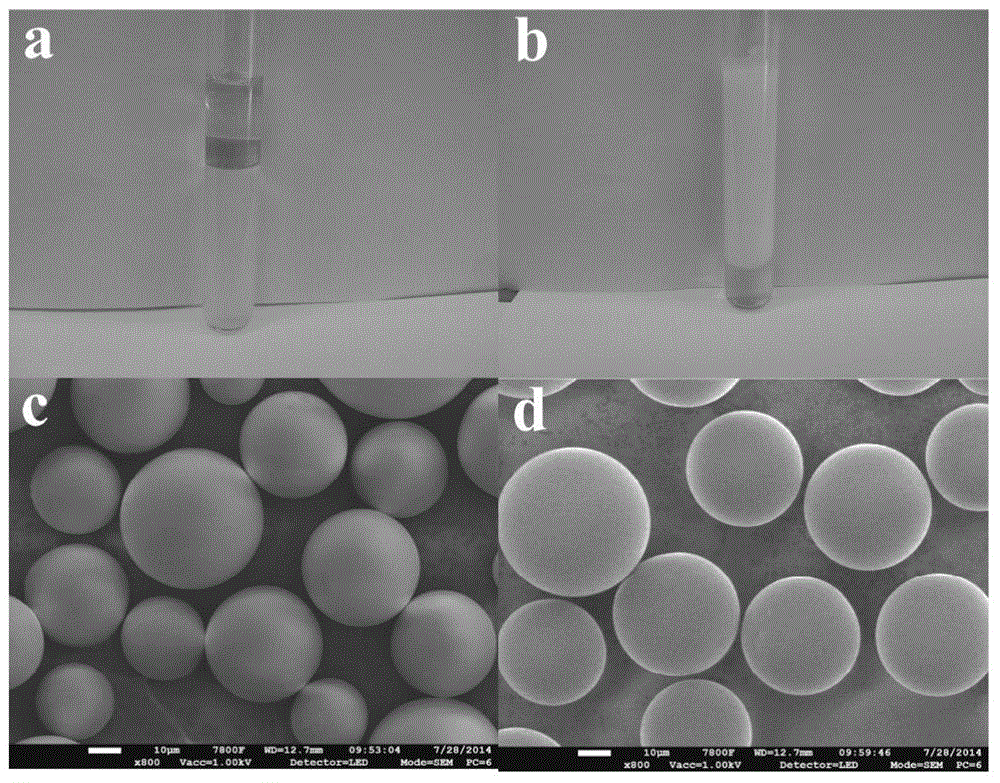

[0032] Preparation of bisphenol A imprinted Pickering emulsion polymer microspheres and their corresponding non-imprinted Pickering emulsion polymer microspheres for selective separation and purification of bisphenol pollutants:

[0033] (1) 0.228g (1mmol) template molecule bisphenol A (BPA), 0.42mL (4mmol) functional monomer 4-vinylpyridine (4-VP), 3.8mL (20mmol) cross-linking agent dimethacrylate Glycol ester (EGDMA) and 40mg initiator azobisisobutyronitrile (AIBN) were dissolved in 3.6mL of porogen toluene, 100Hz ultrasonic 5min to make it evenly mixed to form a pre-polymerization solution, and nitrogen gas was passed through for 10min to remove oxygen for backup use.

[0034] (2) 30mg of SiO 2 Nanoparticles were dispersed in 10 mL of Triton X-100 aqueous solution with a mass concentration of 0.2% by ultrasonication at 100 Hz for 10 min. Then add 4 mL of the pre-polymerization solution obtained in step (1), shake it by hand for 1.0 min to form a stable Pickering emulsion,...

Embodiment 2

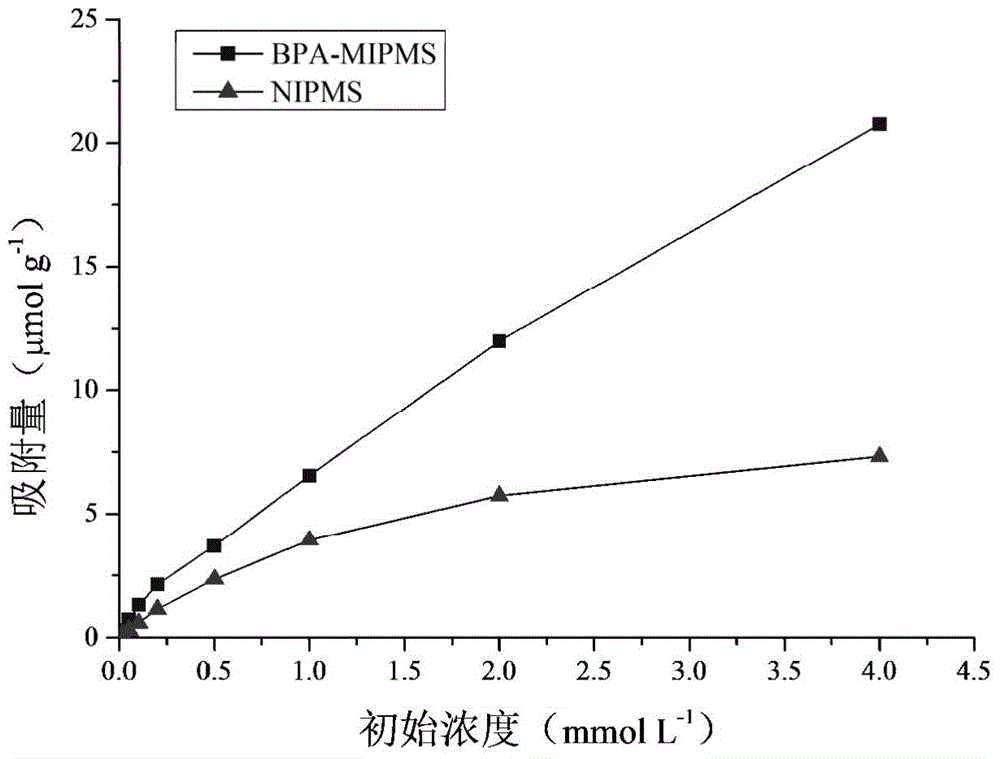

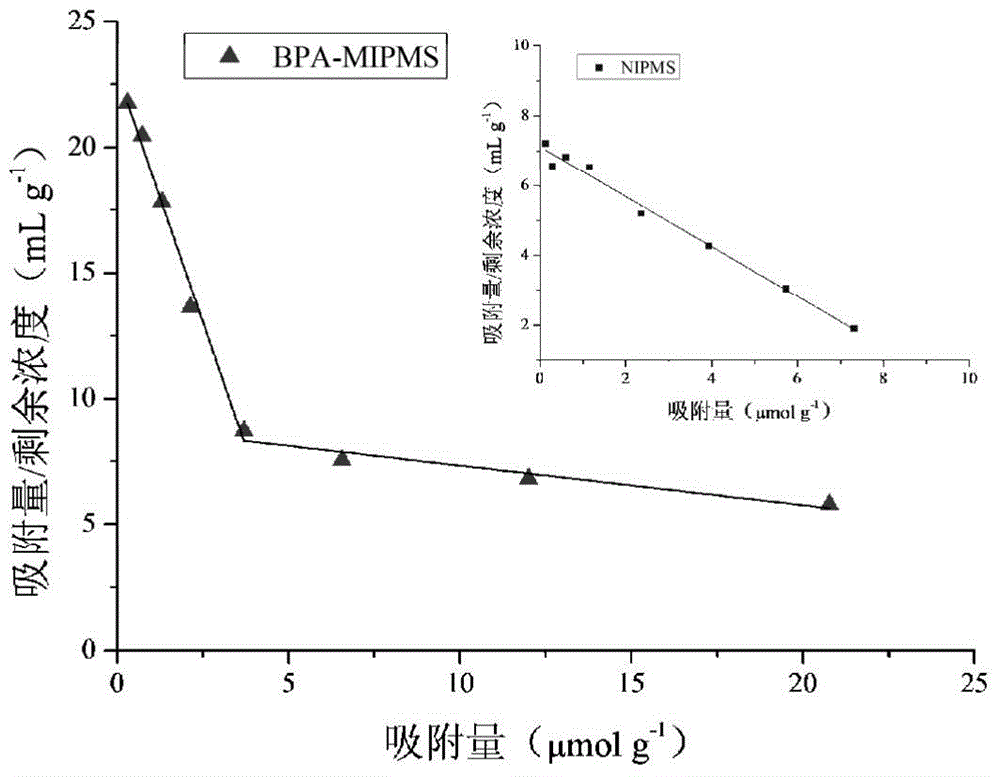

[0039] Static adsorption evaluation is carried out to the material prepared by the method provided by the invention:

[0040] Accurately configure acetonitrile of BPA with a series of concentrations (0.02mmol / L, 0.05mmol / L, 0.1mmol / L, 0.2mmol / L, 0.5mmol / L, 1.0mmol / L, 2.0mmol / L, 4.0mmol / L) The solution is ready for use. Take 2ml of each of the above solutions and place them in separate sample bottles, add 40 mg of bisphenol A imprinted Pickering emulsion polymer microspheres prepared in Example 1 to each sample bottle, and take BPA of serial concentrations configured in addition. Each 2ml of the acetonitrile solution was placed in a separate sample bottle, and 40 mg of the non-imprinted Pickering emulsion polymer microspheres prepared in Example 1 were added to each sample bottle. After continuous shaking at a speed of 150 rpm for 24 hours, the solid-liquid mixture was filtered with a 0.22 μm filter membrane. Utilize Agilent 1200 type high performance liquid chromatography to ...

Embodiment 3

[0043] Evaluate the imprint factor of bisphenol A imprinted Pickering emulsion polymer microspheres prepared by the method provided by the invention to bisphenol pollutants:

[0044] The bisphenol pollutants include: bisphenol A (BPA), bisphenol F (BPF), bisphenol B (BPB), bisphenol E (BPE), bisphenol AF (BPAF), bisphenol S (BPS) , bisphenol AP (BPAP), bisphenol Z (BPZ), tetrabromobisphenol A (TBBPA), estrone (E1), 17β-estradiol (E2), dienestrol (DNS), diethylstilbestrol ( DES), n-octylphenol (OP) and n-nonylphenol (NP).

[0045] The bisphenol A imprinted Pickering emulsion polymer microspheres prepared in Example 1 and the corresponding non-imprinted Pickering emulsion polymer microspheres were packed into stainless steel chromatographic columns (100mm × 4.6mm) with methanol as the dispersion solvent. i.d.), resulting in imprinted and non-imprinted columns. The retention time of the above-mentioned bisphenol pollutants on the imprinted column and non-imprinted column was ob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com