Alkaline anion exchange composite membrane for fuel cell and preparation method thereof

An alkaline anion and fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of poor chemical stability, limit the large-scale application of proton exchange membrane fuel cells, and harsh synthesis conditions, and achieve thermal stability and High mechanical strength, preventing instability and easy decomposition, and easy control of film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

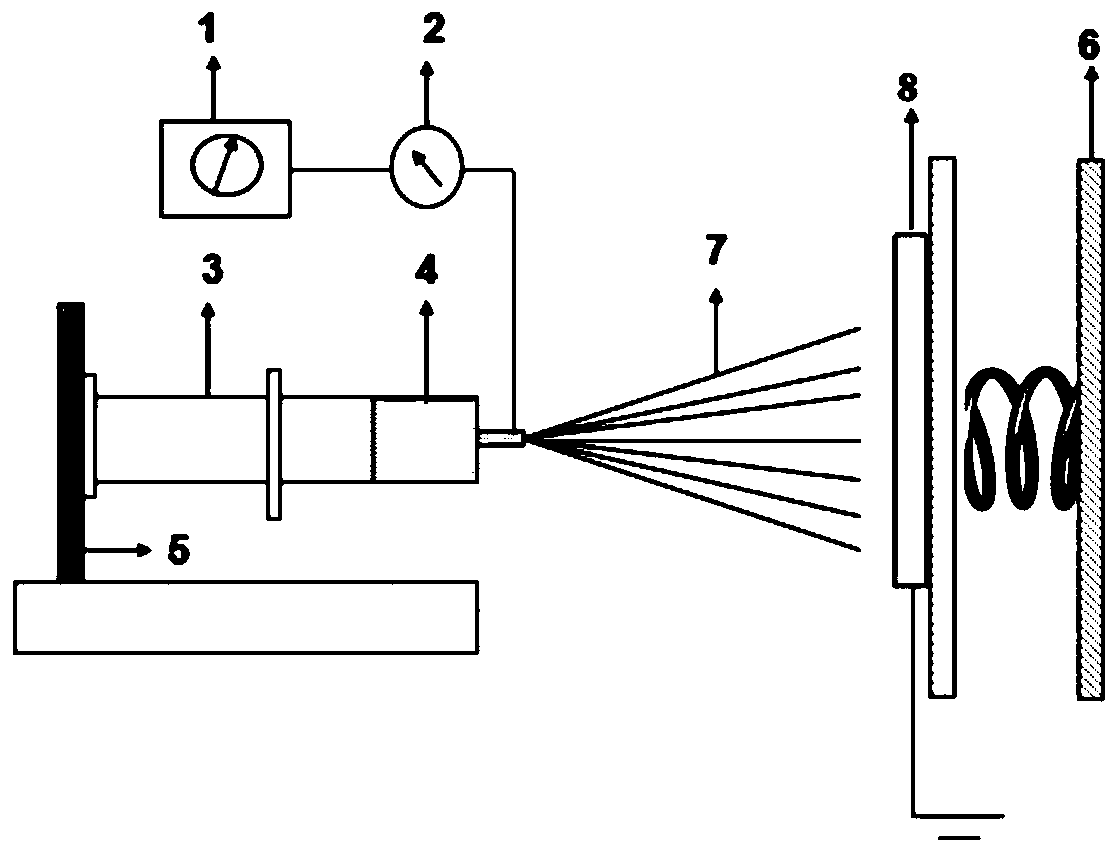

Method used

Image

Examples

Embodiment 1

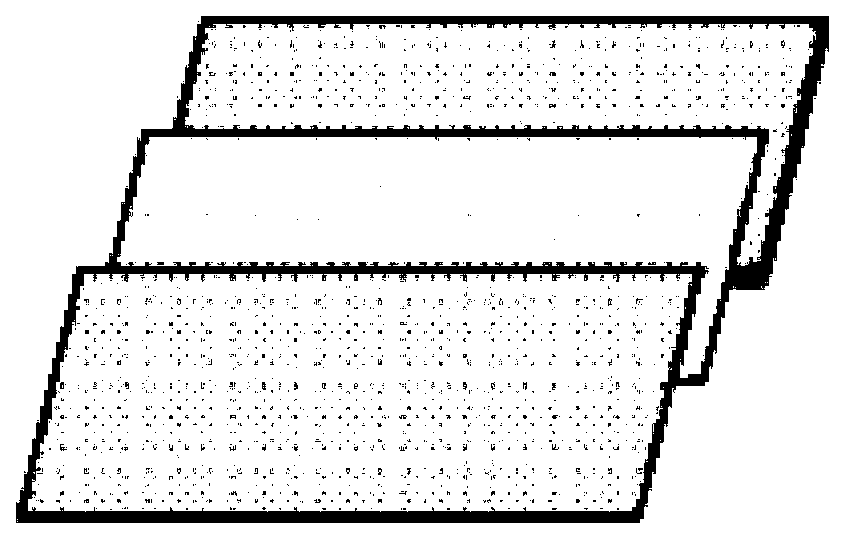

[0033] A method for preparing a fuel cell alkaline anion exchange composite membrane, comprising the following steps:

[0034] 1. Preparation of nano-TiO 2 : Add 2g of coarse titanium dioxide powder into 100mL of NaOH solution with a concentration of 10mol / L, stir magnetically for 30min and mix evenly. Then the above-mentioned pretreated titanium dioxide was transferred to a polytetrafluoroethylene-lined stainless steel reactor for hydrothermal reaction at 120° C. for 10 h. Then take out the reaction kettle, soak the reacted titanium dioxide in 0.1mol / L HCl solution for 2 hours, then sonicate for 60 minutes, wash with deionized water until neutral, and obtain nano-TiO 2 .

[0035] 2. TiO2 2 / Preparation of PVA spinning solution: Dissolve PVA powder in deionized water, heat and magnetically stir at 90°C for 2 hours to obtain a PVA stock solution with a mass fraction of 5%, and take nano-TiO 2 Uniformly dispersed into PVA solution to obtain TiO 2 The mass fraction is 1% TiO...

Embodiment 2

[0040] A method for preparing a fuel cell alkaline anion exchange composite membrane, comprising the following steps:

[0041] 1. Preparation of nano-TiO 2 : Add 2g of coarse titanium dioxide powder into 100ml of NaOH solution with a concentration of 10mol / L, and stir magnetically for 30min to mix evenly. Then the above-mentioned pretreated titanium dioxide was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and reacted at 200° C. for 12 hours. Then take out the reactor, soak the reacted titanium dioxide in 0.1mol / L HCl for 2h, then ultrasonicate for 60min, wash with deionized water until neutral, and obtain TiO 2 Nanoparticles.

[0042] 2. TiO2 2 / Preparation of PVA spinning solution: Dissolve PVA powder in deionized water, heat and magnetically stir at 90°C for 2 hours to obtain a PVA stock solution with a mass fraction of 5%, and take nano-TiO 2 Uniformly dispersed into PVA solution to obtain TiO 2 The mass fraction is 1% TiO 2 / PVA spinning so...

Embodiment 3

[0047] A preparation method of an alkaline anion exchange composite membrane material for a fuel cell, comprising the following steps:

[0048] 1. Preparation of nano-TiO 2 : Add 2g of coarse titanium dioxide powder into 100ml of NaOH solution with a concentration of 10mol / L, and stir magnetically for 30min to mix evenly. Then the above-mentioned pretreated titanium dioxide was transferred to a polytetrafluoroethylene-lined stainless steel reactor, and reacted at 180° C. for 15 hours. Then take out the reactor, soak the reacted titanium dioxide in 0.1mol / L HCl for 2h, then ultrasonicate for 60min, wash with deionized water until neutral, and obtain TiO 2 Nanoparticles.

[0049] 2. TiO2 2 / Preparation of PVA electrospinning solution: Dissolve PVA powder in deionized water, heat and magnetically stir at 90° C. for 2 hours to obtain a PVA stock solution with a mass fraction of 10%. Take a certain amount of nano-TiO 2 , uniformly dispersed into the PVA solution to obtain TiO ...

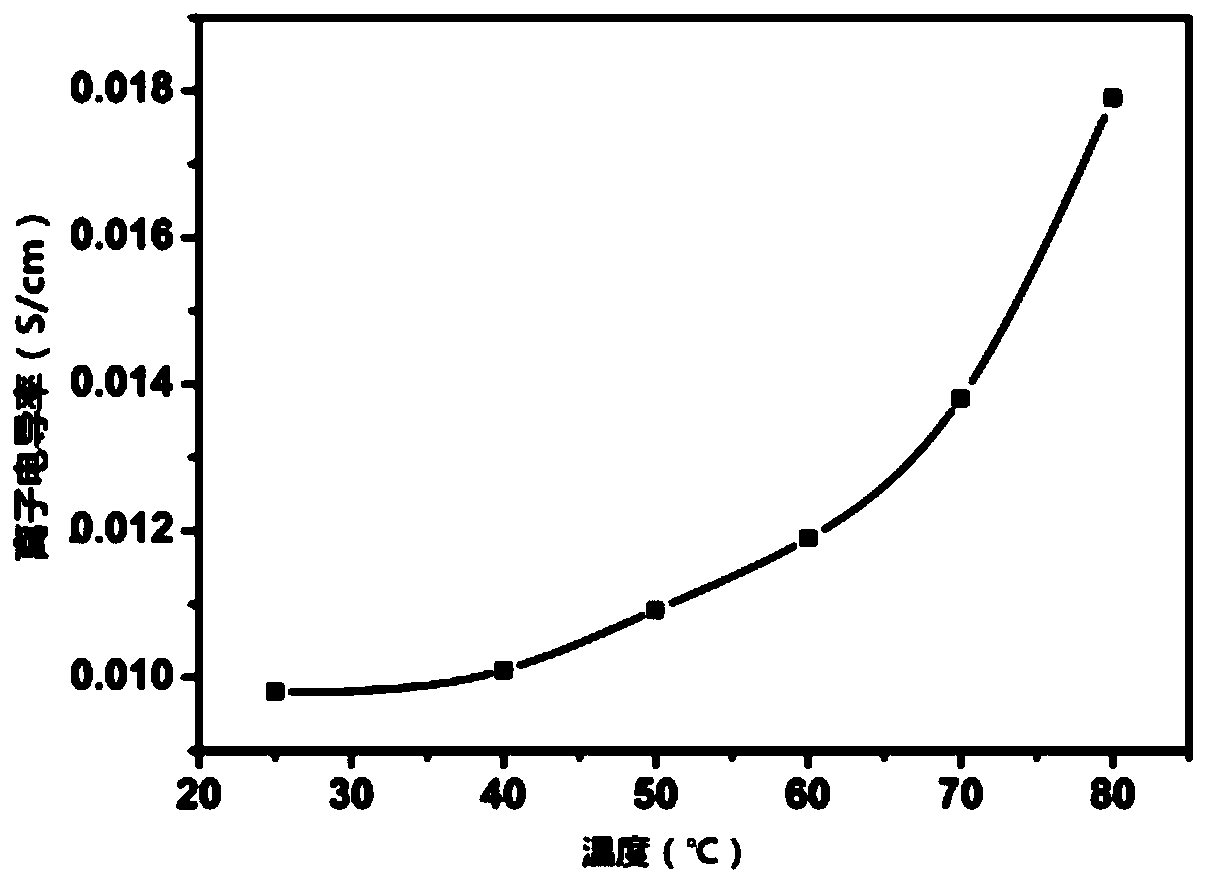

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com