Method for preparing aniline through aqueous-phase catalysis nitrobenzene hydrogenation

A technology for the preparation of nitrobenzene and hydrogen, which is applied in the preparation of amino compounds, chemical instruments and methods, preparation of organic compounds, etc., can solve the problems of catalyst poisoning and deactivation, high production process cost, harsh reaction conditions, etc., and achieves easy separation. , The preparation method is simple and easy to implement, and the equipment requirements are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

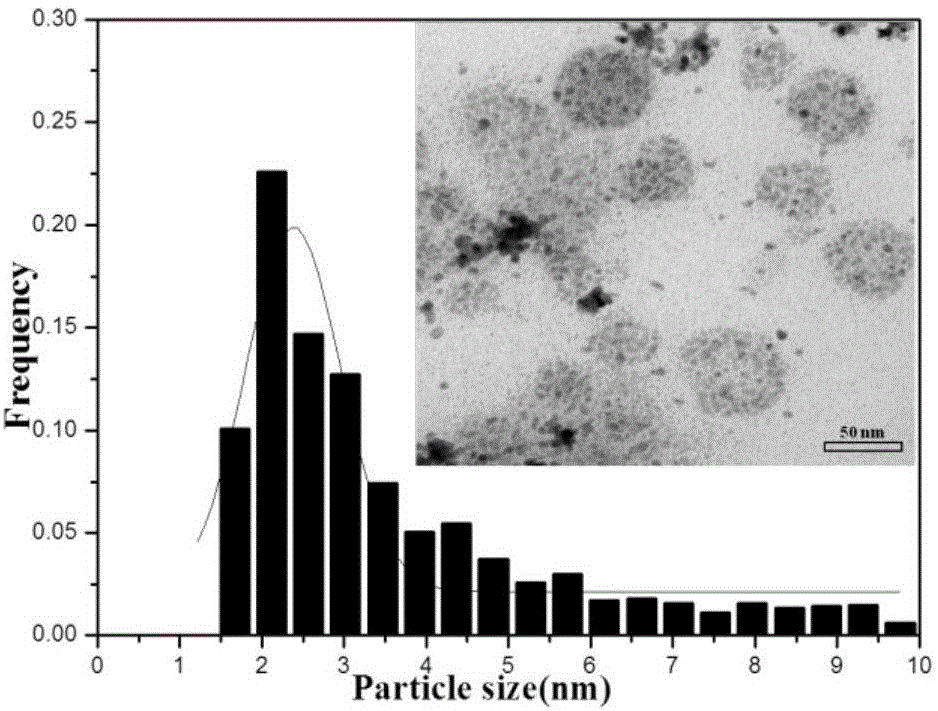

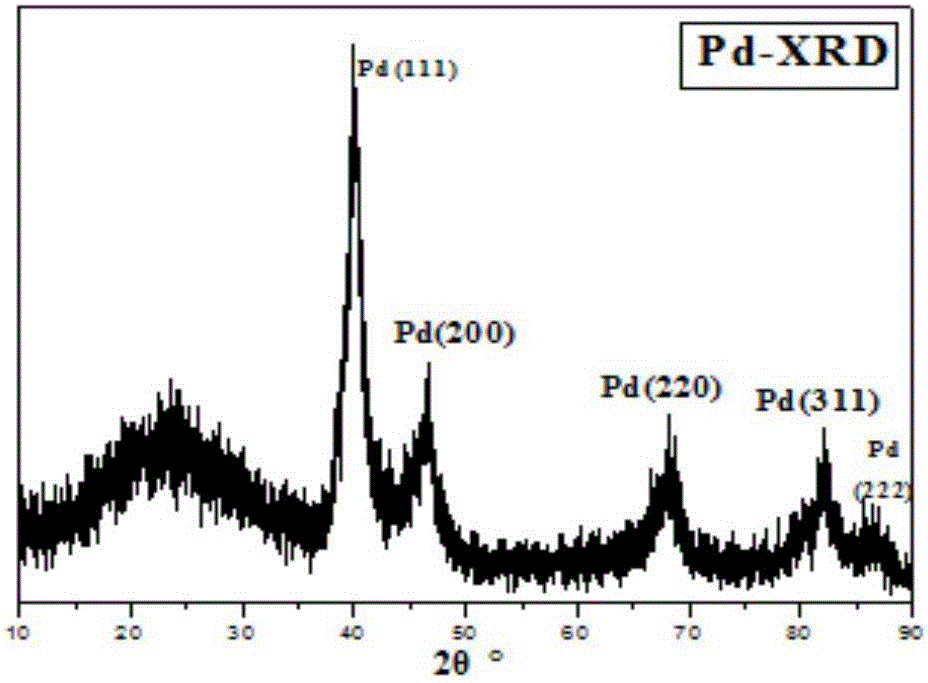

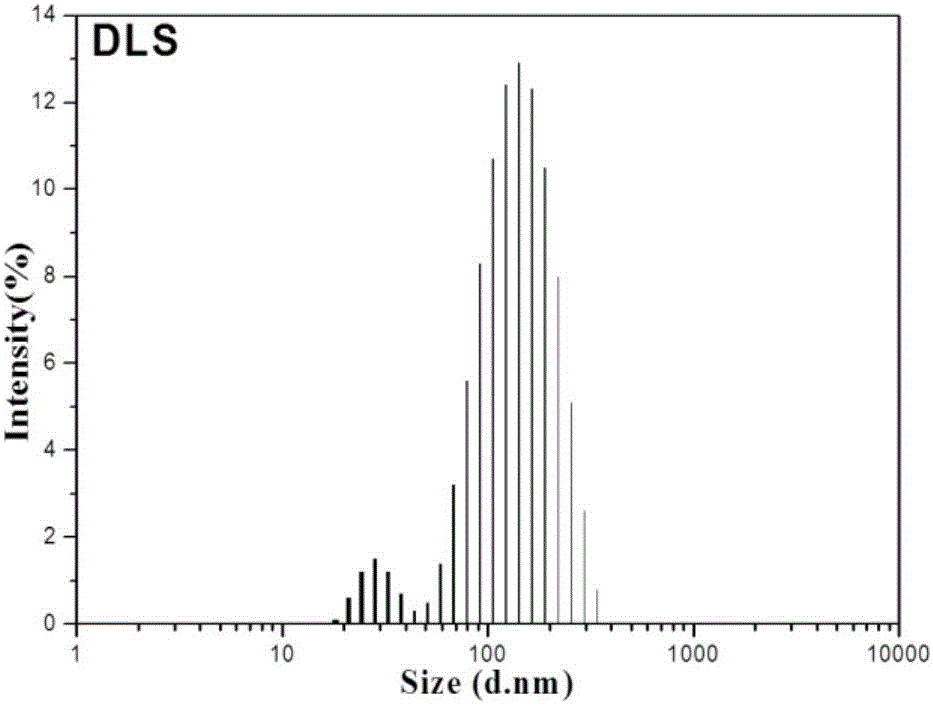

[0017] Add secondary water 10mL, P123 0.1g and Pd(OAc) to 75mL autoclave 2 1×10 -4 mol, stirred at room temperature for 1 h, with H 2 Filled with 1MPa H after replacing 5 times 2 , reacted at 50°C for 1h to obtain a black uniform P123 stable palladium nanoparticle aqueous sol catalyst, named catalyst a 0 (According to the number of uses, the catalyst is named a 0 ~a 6 ). For catalyst a 0 The transmission electron microscope analysis (TEM) is shown in Figure 1, the X-ray diffraction analysis (XRD) is shown in Figure 2, the dynamic light scattering analysis (DLS) is shown in Figure 3 and the laser confocal microscope analysis (CLSM) is shown in Figure 4. The results showed that the prepared palladium nanoparticles were uniformly dispersed, and the average particle size was about 2.5±0.5nm; the average size of P123 micelles was 115.1nm.

Embodiment 2

[0019] Take by weighing nitrobenzene and catalyst a in the ratio of n (nitrobenzene): n (Pd)=500 0 Add to 75mL autoclave, use H 2 Filled with 3MPa H after 5 replacements 2 , react at 45°C for 3h, cool naturally, release the pressure and open the kettle, the catalyst and product are separated into two phases, and the catalyst and product are separated. The composition of the product was determined by gas chromatographic analysis, and the yield of aniline was 100%.

Embodiment 3~8

[0021] Get the catalyst a reclaimed in embodiment 2 n (According to the number of uses, the catalyst is named a 1 ~a 6 ), and take by weighing nitrobenzene in the ratio of the amount of substance n (nitrobenzene):n (Pd)=500, add together in the 75mL autoclave, with H 2 Filled with 3MPa H after 5 replacements 2 , react at 45°C for 3h, cool naturally, release the pressure and open the kettle, separate the catalyst and the product, and determine the composition of the product by gas chromatography. The reusability experiment was carried out seven times, and the catalytic results obtained are shown in Table 1.

[0022] The reusable performance of table 1 catalyst

[0023]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com