Magnetic lithium ion sieve and method for preparing same

An ion sieve and magnetic technology, which is applied in the field of lithium extraction, can solve problems such as affecting the formation of spinel, being easily oxidized, and affecting production, and achieves the effects of reducing dissolution loss, easy large-scale production, and reducing manganese dissolution loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

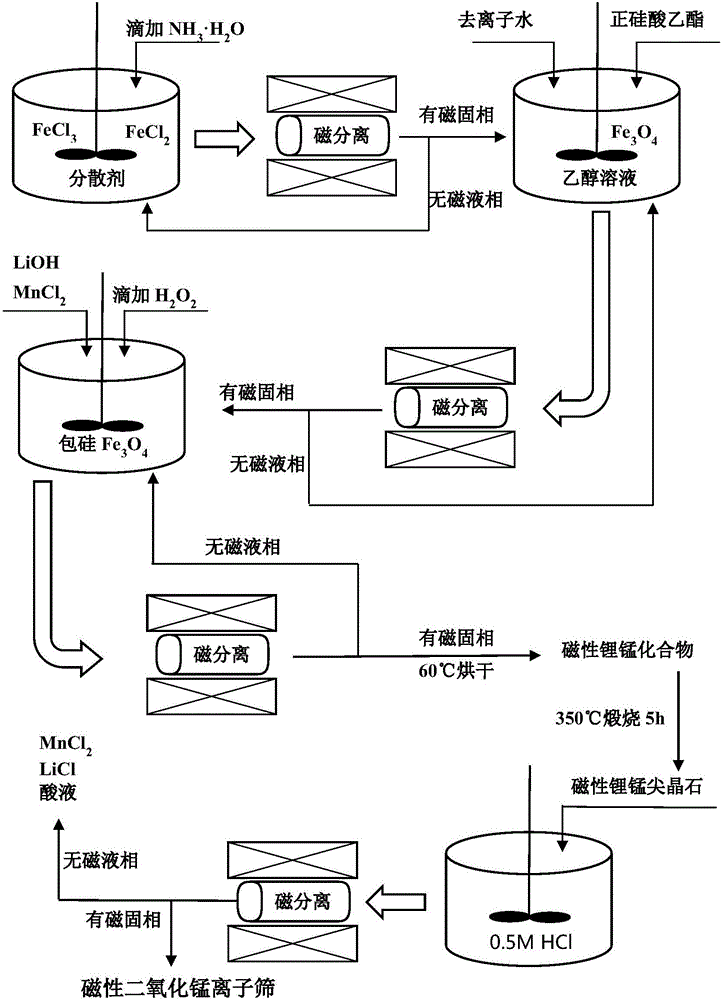

Method used

Image

Examples

Embodiment 1

[0037] Prepare 1 ton of magnetic manganese dioxide ion sieve, add 0.5 g / l concentration of urea as a dispersion system, and add 0.17-0.18 t of ferrous chloride and 0.26-0.27 t of sulfurous acid at a molar ratio of 1:1.5 under the condition of 500 rpm stirring Iron solution, then slowly add 10% ammonia water 900-1000 L ammonia solution through a peristaltic pump until the solution pH=7.0, the black precipitate is ferroferric oxide magnetic core, and its average particle size is 20±3 nm. The above mixed solution is pumped into a φ300 mm slurry electromagnetic separator, which is filled with a stainless steel rhombic mesh as a high gradient medium. The magnetic component is ferroferric oxide magnetic core, which is washed by air-water mixed pulse, and the ferroferric oxide magnetic core is pumped into the silicon-coated mixing tank. The non-magnetic liquid phase component is unreacted ammonia water, which is directly returned to the stirring tank. barrel, this reflux process can ...

Embodiment 2

[0042] Embodiment 2: extract lithium from brine:

[0043] A certain brine contains lithium 0.3g / l, magnesium 100g / l, potassium 0.6g / l, sodium 1.3g / l, brine pH=5.0-5.3, add 10g / l magnetic manganese dioxide to the brine delivery pipeline Ion sieve, use sodium hydroxide to adjust the brine pH>5.0, and then use a 1.25m diameter slurry electromagnetic machine for magnetic separation, with a magnetic field strength of 1.3T, and a diamond-shaped media mesh for high gradient media. The above-mentioned magnetic separation can realize the treatment capacity of 300 tons of brine per hour. The magnetic separation process integrates three process steps: ion sieve capture, ion sieve cleaning in the magnetic field, and desorption liquid elution outside the magnetic field, as follows: After magnetic separation, the non-magnetic liquid phase component is brine after lithium extraction, which can be directly discharged; The magnetic part, that is, the magnetic ion sieve is trapped on the surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

| adsorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com