Silk fibroin modified depression structure lactic acid-based polymer drug-carrying microsphere and method for preparing same

A technology of drug-loaded microspheres and silk fibroin, which is applied in the field of biomedicine, can solve the problems of disintegration of drug-loaded particles, destruction of sustained-release preparations, dissolution of hydrophobic drugs, etc. Compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1: the preparation of silk fibroin aqueous solution:

[0041] Take 1g of silk fibroin powder, place it in 5mL LiBr (9.3M) aqueous solution, stir slowly at 60°C for 4h to produce a 20% solution, transfer the resulting solution to a dialysis bag (MWCO 3500), and dialyze with distilled water for 4d (change the water every 4h Once), the obtained solution was centrifuged at 8,000 rpm for 20 min, and repeated 3 times to remove insoluble matter, and then the obtained solution was passed through a 0.45 μm filter membrane. By measuring the weight of a certain volume of the silk fibroin aqueous solution after freeze-drying, the concentration of the silk fibroin aqueous solution is about 3%. And dilute it into a silk fibroin aqueous solution with a concentration of 0.5%-2%, and store the stock solution at 4°C for use.

Embodiment 2

[0043] Dimple structure lactic acid-based polymer microspheres are made by the following method:

[0044] (1) Dissolving the lactic acid-based polymer in dichloromethane to make a solution 1 with a concentration of 10 mg / mL;

[0045] (2) Add solution 1 to a 1% polyvinyl alcohol aqueous solution with a mass concentration of 1% at a stirring speed of 800 rpm, and the volume ratio of the solution 1 to the polyvinyl alcohol aqueous solution is 1:5;

[0046] (3) Continue to stir for 3 hours, centrifuge, remove the supernatant, wash with deionized water, and freeze-dry to obtain lactic acid-based polymer microspheres with pit structure.

[0047] The lactic acid-based polymer is a polylactic acid-glycolic acid copolymer with a weight average molecular weight of 10,000–50,000.

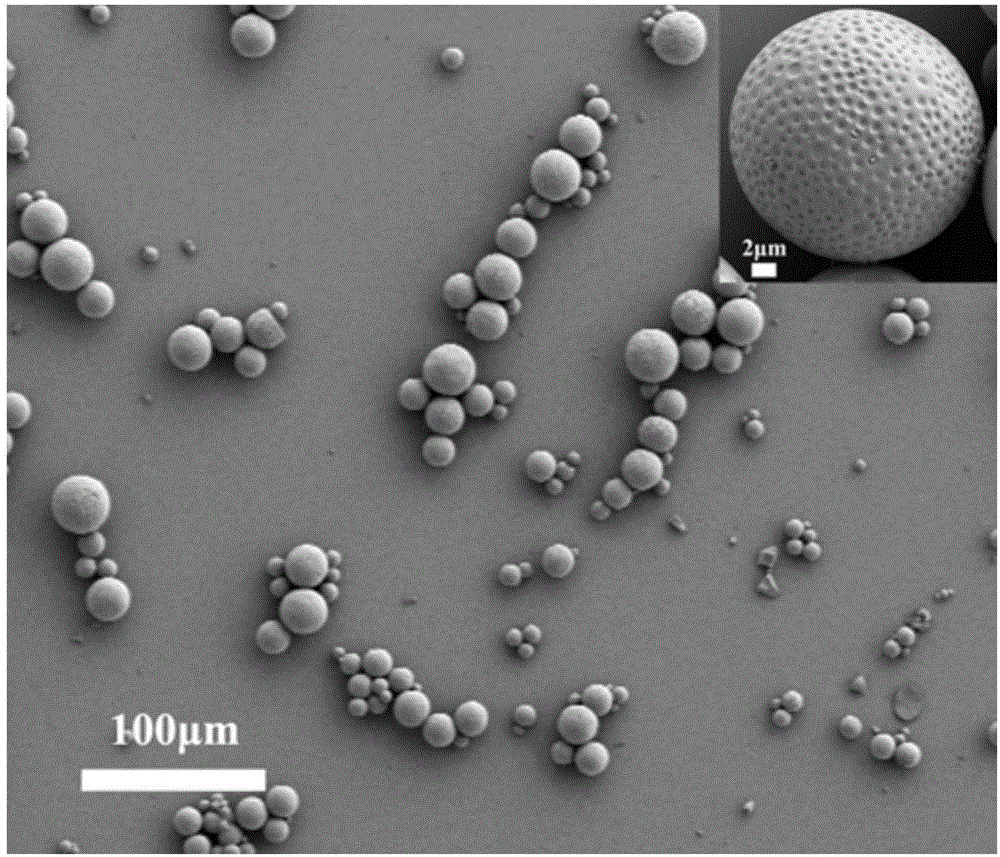

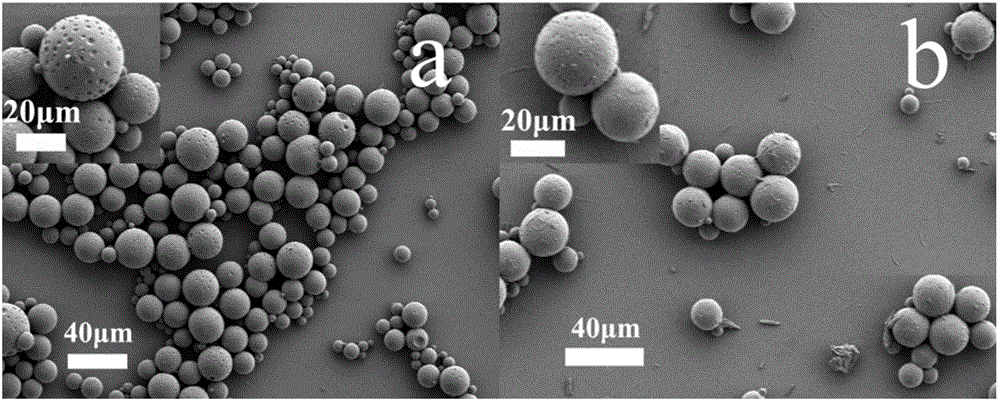

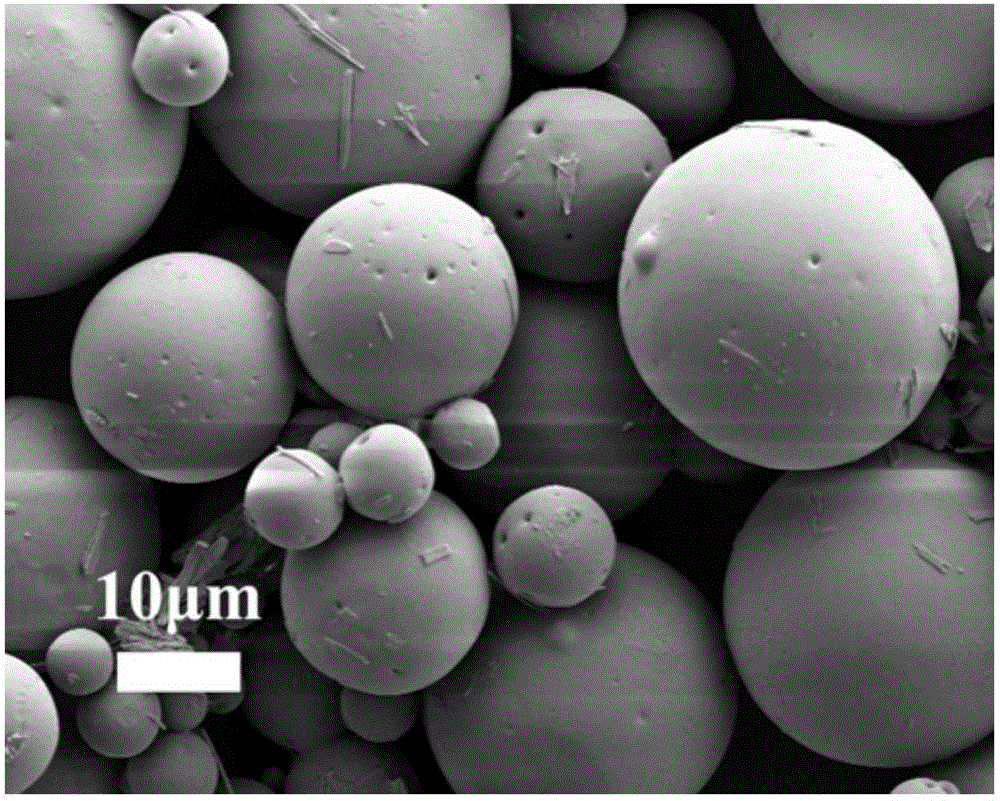

[0048] The yield of the obtained pit-structured lactic acid-based polymer microspheres was 82%. The SEM pictures of the microspheres are shown in figure 1 , its shape is spherical, the diameter is 6.8-29.3μ...

Embodiment 3

[0050] Dimple structure lactic acid-based polymer microspheres are made by the following method:

[0051] (1) Dissolving the lactic acid-based polymer in dichloromethane to make a solution 1 with a concentration of 5 mg / mL;

[0052] (2) Add solution 1 to a 0.5% polyvinyl alcohol aqueous solution with a stirring speed of 400 rpm, and the volume ratio of the solution 1 to the polyvinyl alcohol aqueous solution is 1:10;

[0053] (3) Continue to stir for 2 hours, centrifuge, remove the supernatant, wash with deionized water, and freeze-dry to obtain lactic acid-based polymer microspheres with a pit structure.

[0054] The lactic acid-based polymer is a polylactic acid-glycolic acid copolymer with a weight average molecular weight of 10,000–50,000.

[0055] Yield and shape were similar to Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com