Antibacterial hexapeptide derived from Pediococcus lactis and preparation method thereof

An antimicrobial peptide and amino acid technology, applied in the field of bioengineering, can solve problems such as the decline of immune function of livestock and poultry, endogenous infection of animals, and the production of drug-resistant strains, etc. It achieves good pH stability and thermal stability, mild operating conditions, The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of lactobacillus R16

[0040] Prepare antibacterial hexapeptide lactobacillus R16 according to the following method:

[0041] 1. The antibacterial hexapeptide is fermented by Pediococcus lactis. After the fermentation supernatant is centrifuged, the supernatant is collected by ultrafiltration (molecular weight cut-off 10000Da) and concentrated 8-10 times to obtain a crude extract.

[0042] 2. Separation by anion-exchange chromatography Hitrap Q FF: the crude extract was loaded on the Hitrap Q FF chromatographic column to separate two elution peaks, and the active peak with antibacterial effect on Escherichia coli was collected, and the collected active peak L2 Freeze-dried after extensive dialysis with Mill-Q water.

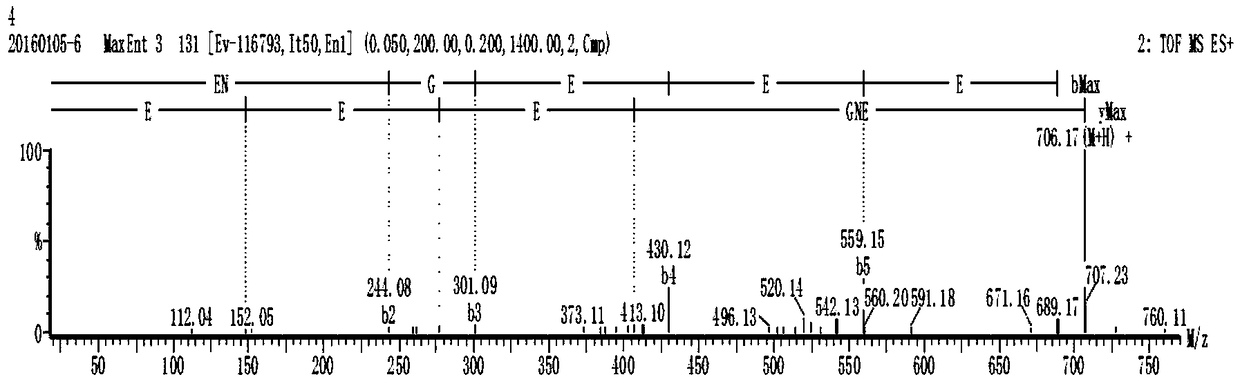

[0043] 3. Separation by gel filtration chromatography Superdux Peptide 10 / 300GL: put the elution peak L2 of anion exchange chromatography on the Superdux Peptide 10 / 300GL gel filtration chromatography column, separate and obt...

Embodiment 2

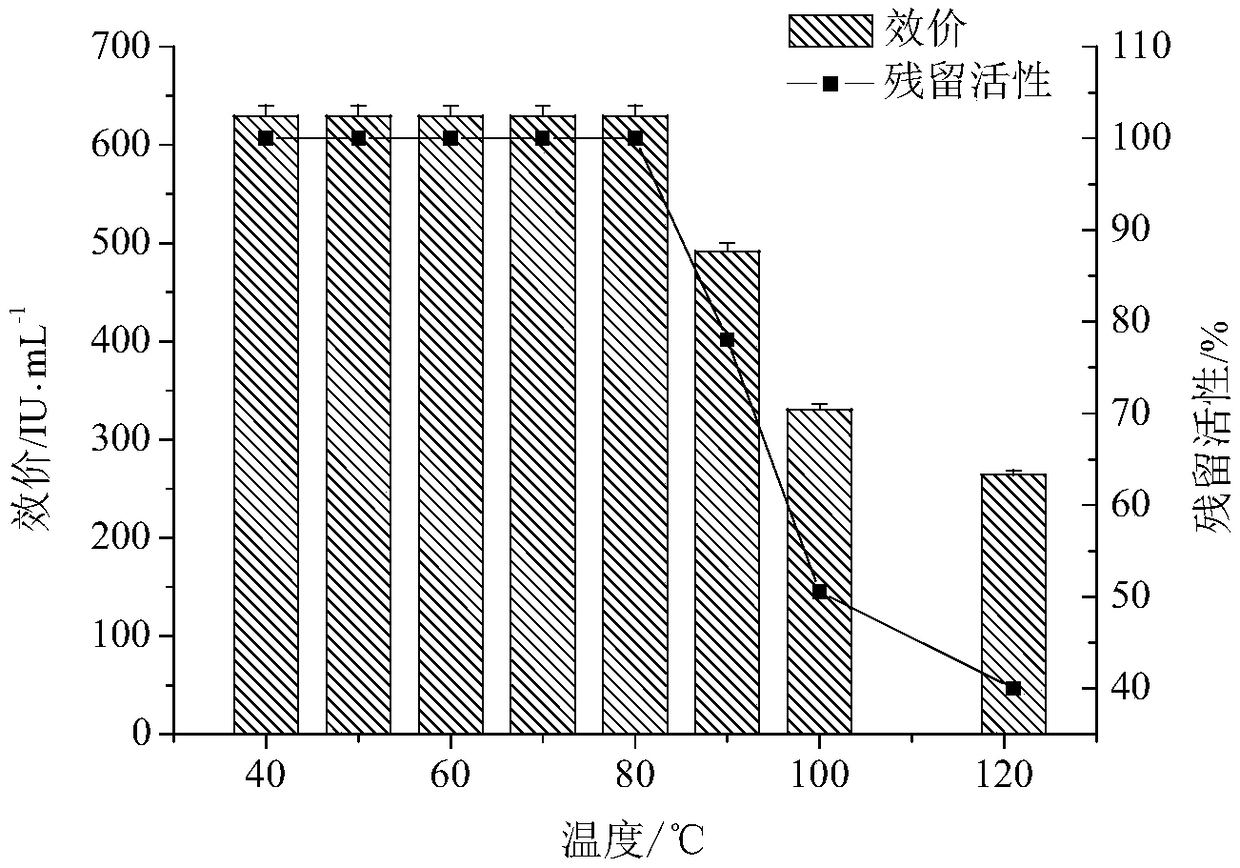

[0048] Embodiment 2: the biological characteristic of lactobacillus R16

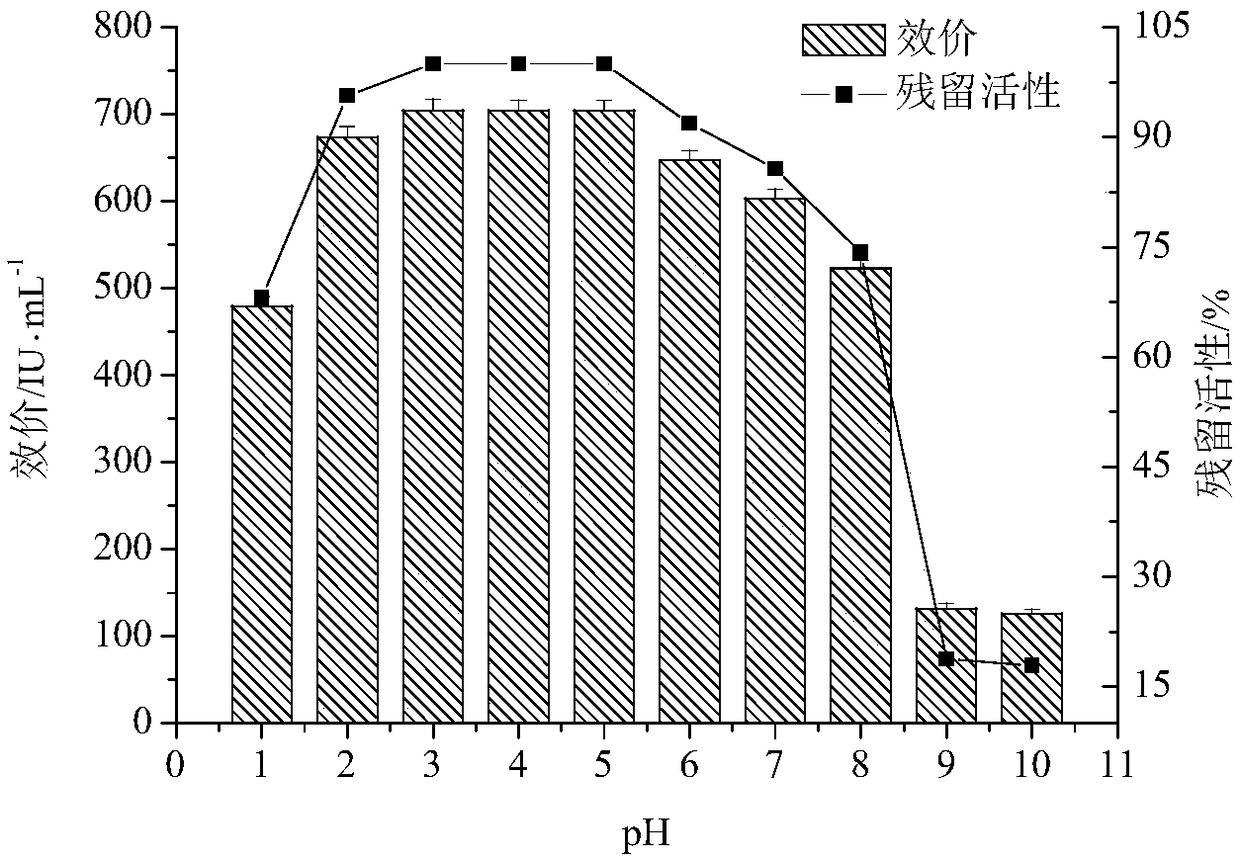

[0049] (1) Stability of lactobacillus R16 in pH

[0050] Take 10 parts with a concentration of 100mg·mL -1 Purified active substance lactobacillus R16, with 1.0mol L -1 NaOH and 1.0mol L -1 Adjust the pH to 1.0-10.0 with HCl, place it in a water bath at 37°C for 2 hours, and then adjust the pH to 4.5 [62] , do antibacterial experiment, observe its inhibition to Escherichia coli. The result is as figure 2 shown.

[0051] figure 2 It was shown that the antibacterial activity of lactobacillus R16 reached the maximum at pH 3.0-5.0. At pH 6.0-8.0, the antibacterial activity of lactic acid bacterium R16 gradually decreased, and the decreasing trend was slow, and the residual activity was maintained at about 75%, indicating that the stability of lactic acid bacterin R16 decreased to a certain extent under this pH condition, but this pH has no effect on lactic acid bacteria. The stability of prime R16 ...

Embodiment 3

[0080] Embodiment 3: the application of lactobacillus R16

[0081] Application method:

[0082] (A) Grind the soybean meal with a blade grinder, take 4 portions, put 40g of each portion into a 500mL fermentation bottle, numbered as Group 5, Group 6, Group 7, and Group 8, and sterilize at 105°C for 10 minutes.

[0083] (B) See Table 3 for fermentation conditions.

[0084] Table 3 Initial fermentation conditions of soybean meal containing lactobacillus R16

[0085]

[0086] (C) The national standard for the determination of coliform bacteria in feed is used to measure the number of E. coli.

[0087]By adding E. coli to sterilized soybean meal, the inhibitory effect of lactobacillus R16 on E. coli in soybean meal was studied. The results showed that when no lactobacillus R16 was added, the number of Escherichia coli was changed from 1380 per 100g before fermentation -1 Increased to 4×10 post-fermentation 6 100g -1 , after adding lactobacillus R16, the number of Escherich...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com